Torque measuring device of small engine

A technology of engine torque and measuring device, applied in measuring device, engine testing, torque measurement and other directions, can solve problems such as difficulty in accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A small engine torque measuring device of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

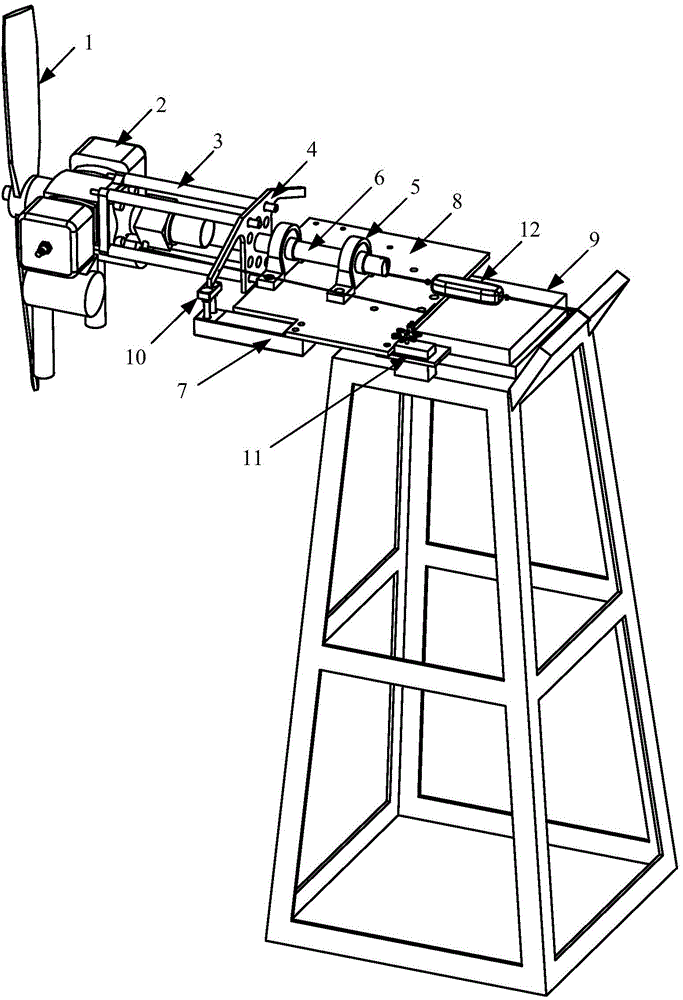

[0023] figure 1 It is a schematic diagram of the overall structure of a small engine torque measuring device provided by the present invention. The small-sized engine refers to an aircraft model engine, and the general power range is between 0.5kW and 15kW.

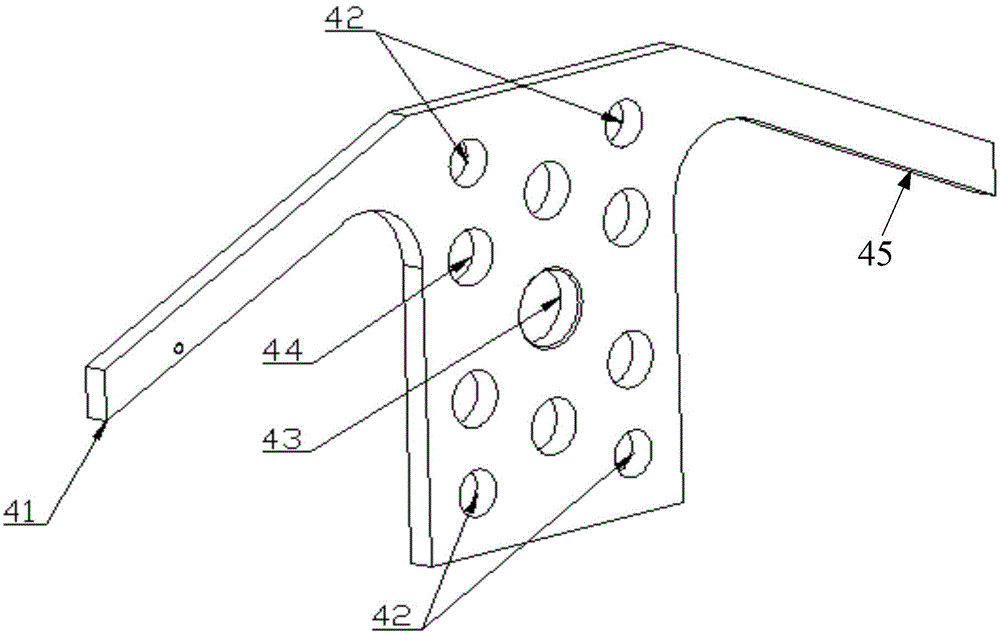

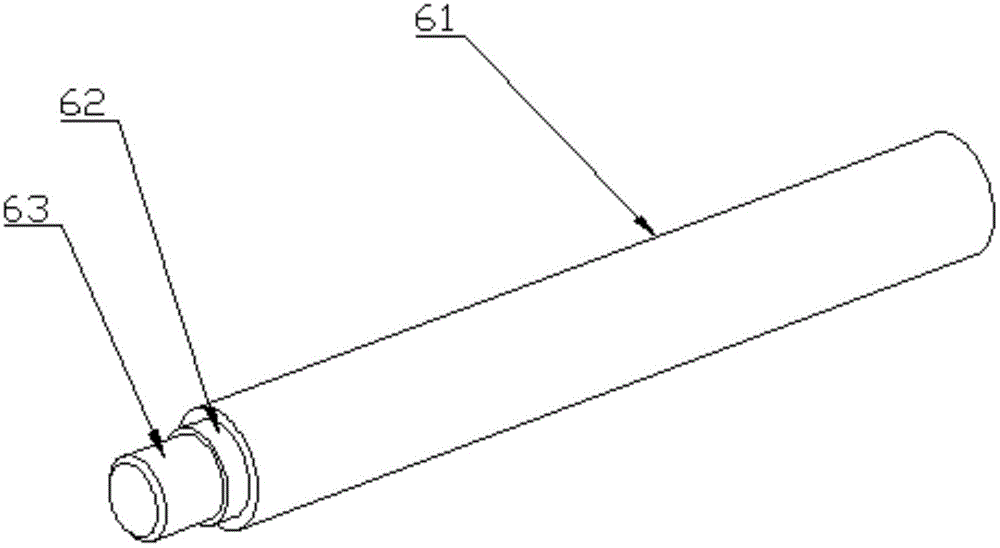

[0024] Described torque measuring device comprises: propeller 1, engine to be tested 2, connecting screw rod 3, double-arm steel plate 4, support bearing 5, support polished rod 6, pressure sensor 7, total support plate 8, the stand 9 that has sliding guide rail , pressure plate 10, steering gear 11 and tension gauge 12. Among them, the propeller 1, the engine to be tested 2, the connecting screw 3, the double-arm steel plate 4 and the supporting polished rod 6 constitute the cantilever system, and the supporting bearing 5, the total supporting plate 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com