Underwater detection air inlet leakage-preventing device of fuel oil tank

A leak-proof device and fuel tank technology, which is applied in the direction of using liquid/vacuum for liquid tightness measurement, etc., can solve the problems of laborious, unsmooth insertion of plugs, and easy to loose plugs, so as to achieve smooth and labor-saving insertion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

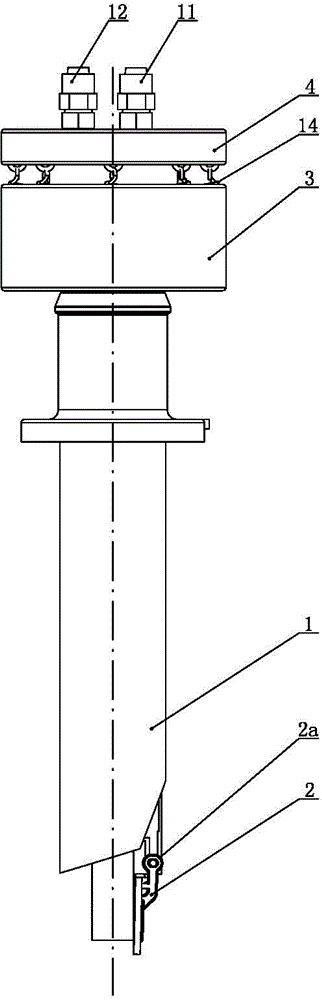

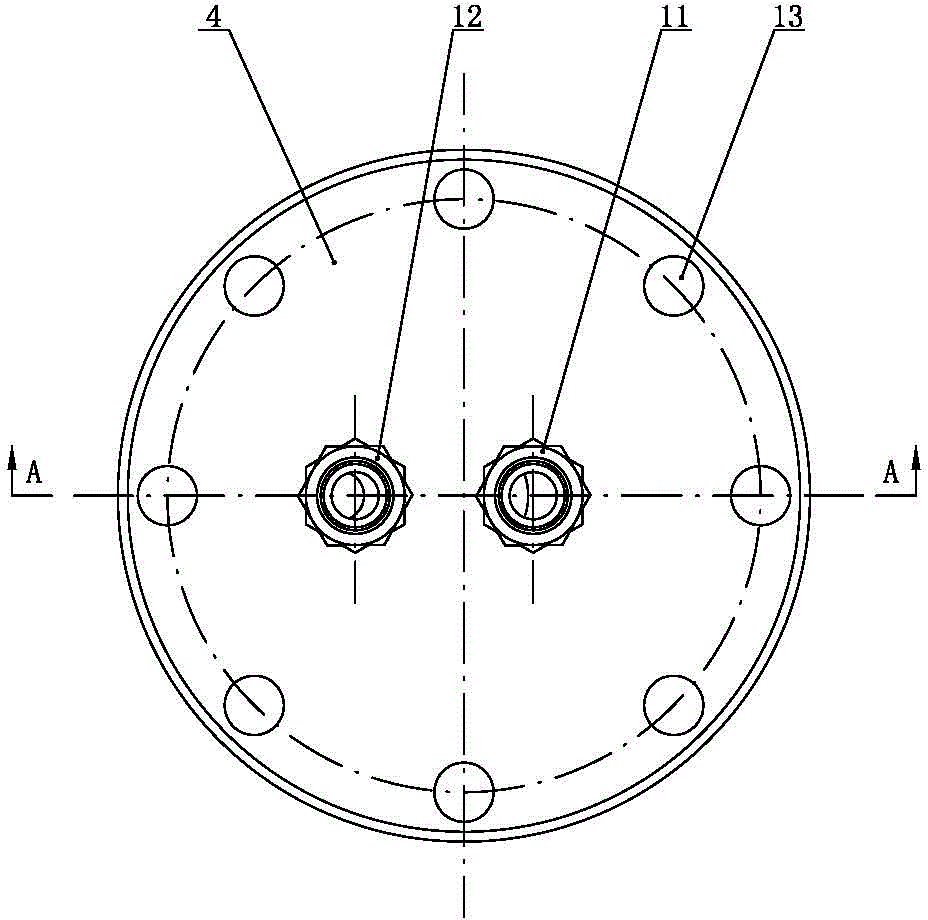

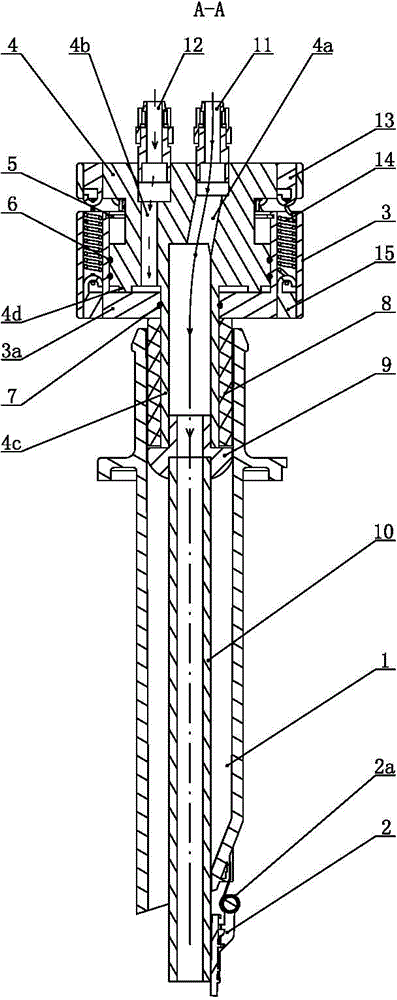

[0021] like Figure 1 to Figure 7 As shown, the fuel tank underwater detection air intake leak prevention device of the present invention includes a fuel tank body, which is connected with a fuel injection pipe 1, and the lower port of the fuel injection pipe 1 is equipped with a throttle cover 2, and the hinge of the throttle cover 2 A valve spring 2a is arranged on the shaft, and the tension of the valve spring 2a makes the throttle cover 2 normally closed and can be opened downward. A gas injection pipe 4c is inserted into the upper port of the oil injection pipe 1, a rubber sleeve 8 is provided between the outer wall of the gas injection pipe 4c and the inner wall of the oil injection pipe 1, and the lower port of the gas injection pipe 4c is provided with an internal thread and is screwed with a mushroom head screw 9 , The mushroom head screw 9 is provided with a through hole along its own axis. The lower end of the through hole of the mushroom head screw 9 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com