Variable mach number transonic rigid free jet nozzle

A Mach number and transonic technology, which is applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as difficulty in ensuring the rectangular section of the nozzle outlet, limited test Mach number range, and poor repeatability of rigid panels. Achieve the effects of improving efficiency and practicability, simple design, and uniform flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

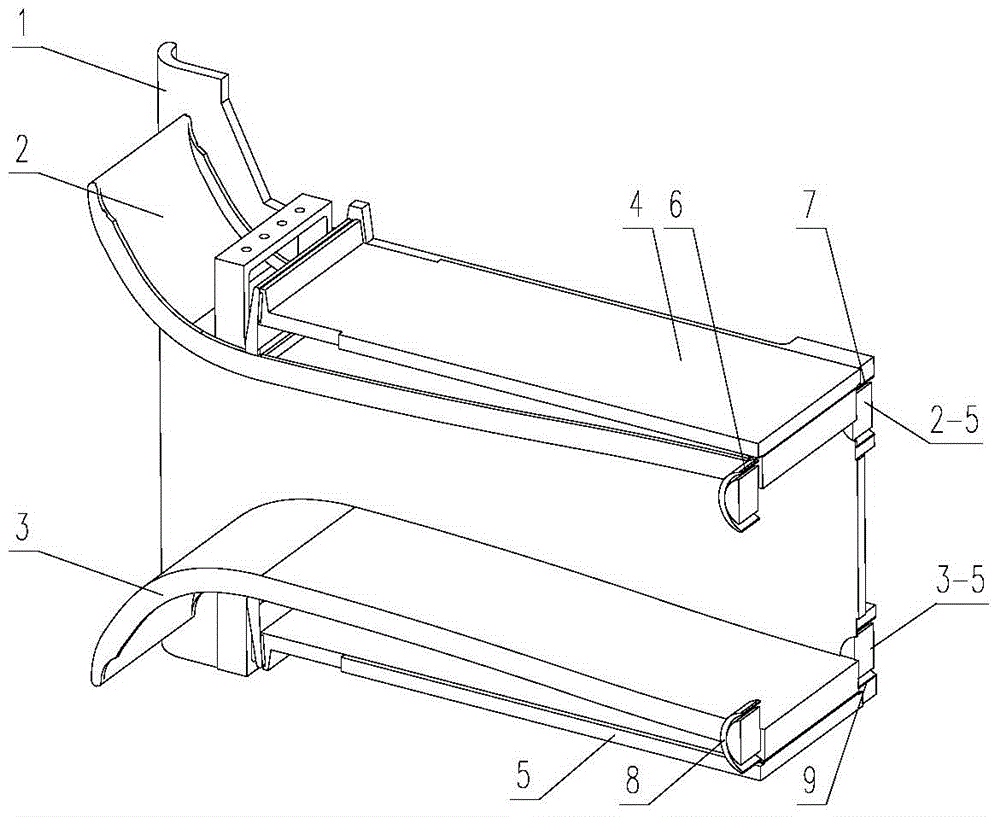

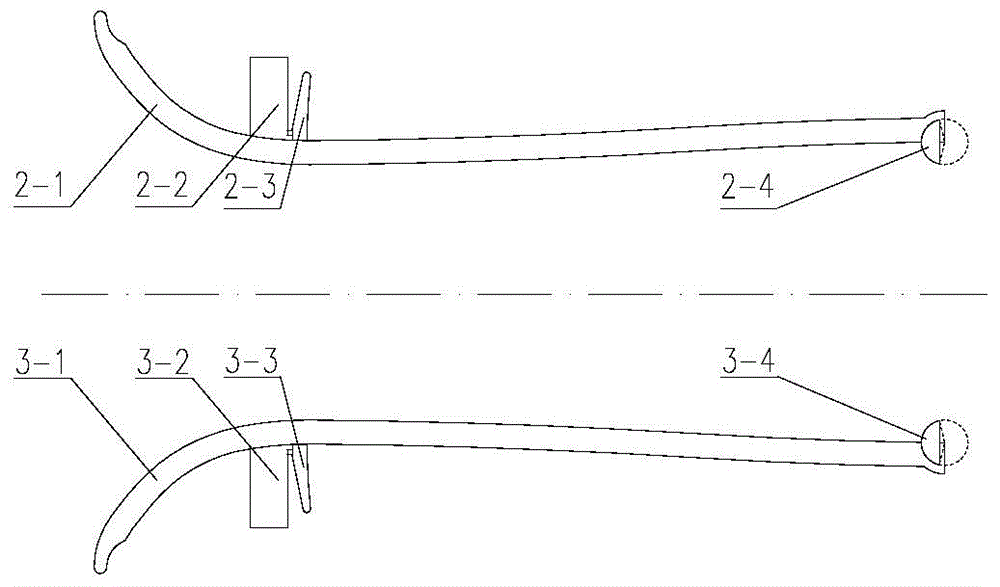

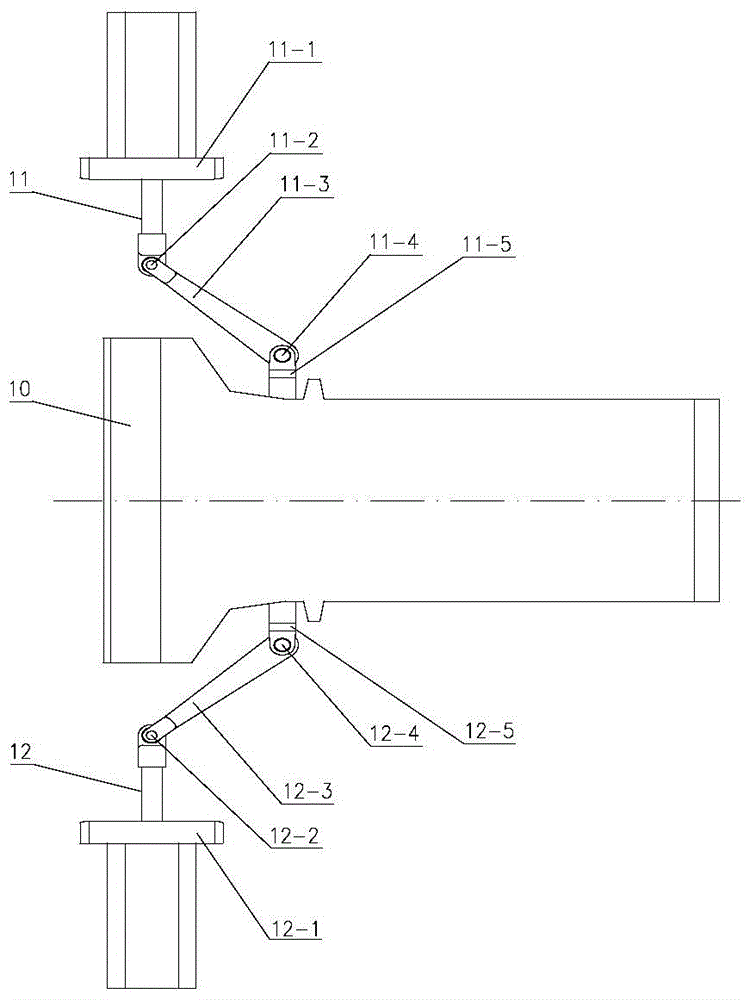

[0026] See attached Figures 1 to 3 , a free-jet transonic rigid nozzle with a variable Mach number of the present invention, comprising a symmetrical left side wall 1, a right side wall 10, an upper support plate 4 and a lower support plate 5, a left side wall 1 and a right side wall The wall 10 is fixed in position by the symmetrically arranged upper support plate 4 and the lower support plate 5 and is supported and connected to form an open nozzle frame; the upper profile mechanism 2 and the lower profile mechanism 3 are symmetrically arranged on the nozzle frame Inside, it is characterized in that it also includes an upper right semicircular bearing 6, an upper left semicircular bearing 7,

[0027] Wherein the upper profile mechanism 2 includes an upper profile panel 2-1, an upper right semicircle lug 2-4, an upper left semicircle lug 2-5, an upper right semicircle lug 2-4, and an upper left semicircle lug 2-5. The left and right sides of the outlet end of the top panel 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com