Abrasive particle shear fatigue test equipment

A technology of fatigue testing and abrasive particles, which is applied in the direction of testing the strength of materials by applying a stable shear force, and can solve the problems of quantitative analysis of abrasive particle shear fatigue characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below by embodiment the content of the present invention is specified:

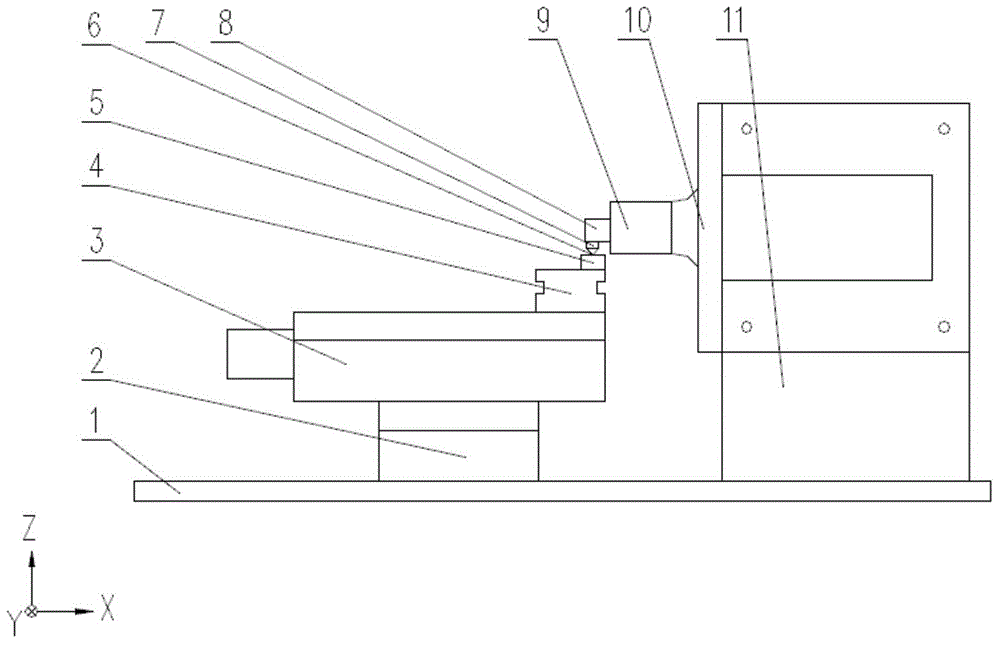

[0037] Please check figure 1 , a kind of abrasive grain shear fatigue testing equipment, comprises abrasive grain 6 and the scratched sample 5 that shears and slides with abrasive grain 6; Described abrasive grain 6 is brazed or bonded on a tool head 7 top; Also Including base system, ultrasonic vibration system, force measurement system and acoustic emission system;

[0038] The base system includes an optical flat plate 1, an X-axis sliding table 3, a Y-axis sliding table 2 and a Z-axis sliding table 11; the Y-axis sliding table 2 is slidably mounted on the optical flat plate 1 and can slide along the Y-axis direction; X Axis sliding table 3 is slidably attached to Y-axis sliding table 2 and can slide along the X-axis direction; Z-axis sliding table 11 is slidably attached to optical flat plate 1 and can slide along the Z-axis direction; the X-axis direction, Y The axis direction is perpendicul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com