Constant acceleration and constant deceleration curve components of cam profile generator

A cam profile, iso-acceleration technology, applied in the direction of instruments, educational appliances, teaching models, etc., can solve problems such as not easy, to achieve the effect of simple and clear teaching, strong demonstration, promoting enthusiasm and creativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

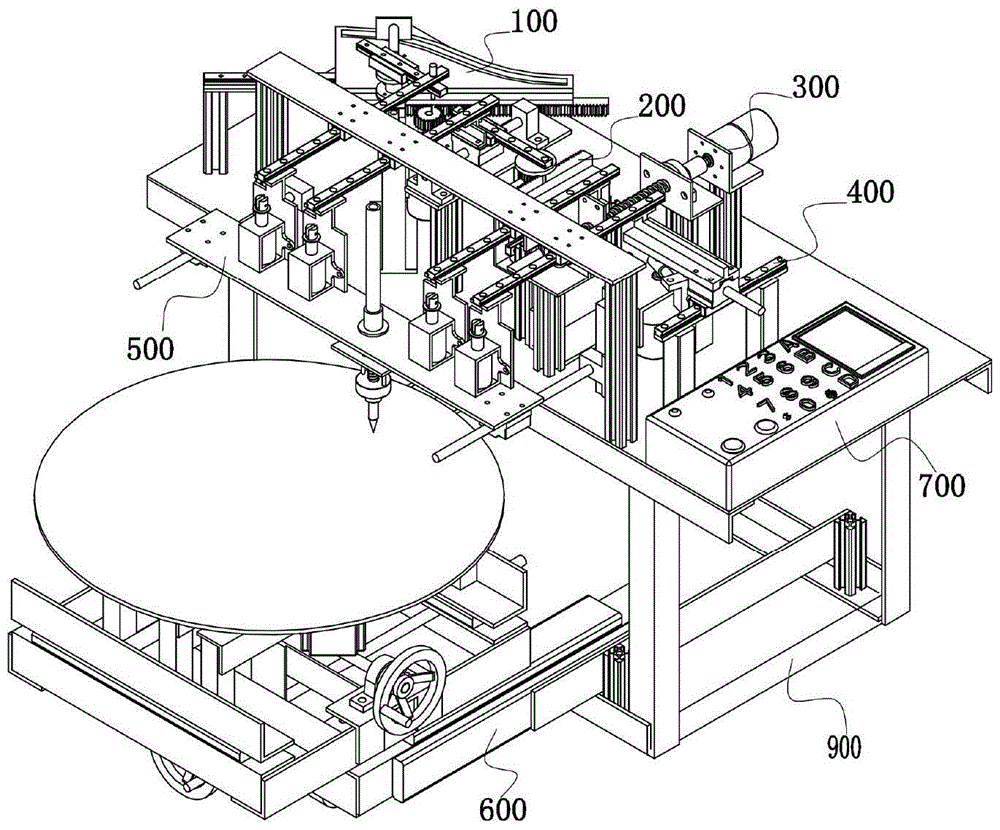

[0033] Such as Figure 1 to Figure 8 Shown, the present invention will be further described below in conjunction with accompanying drawing.

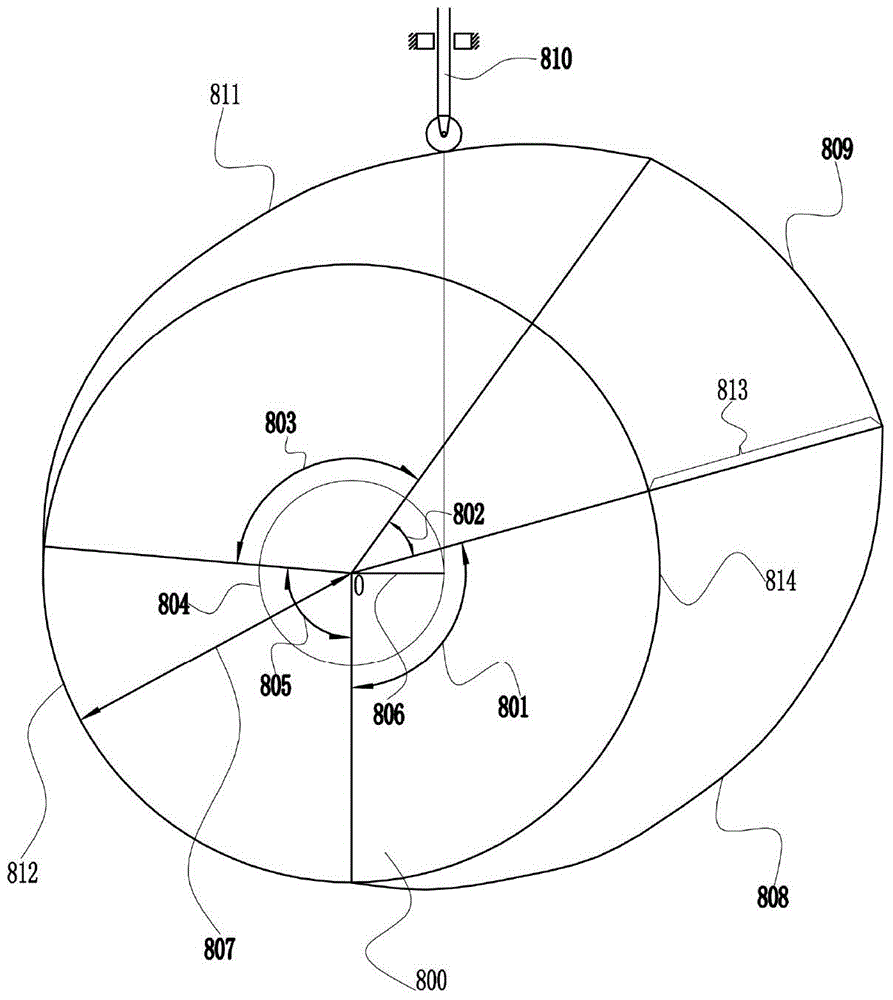

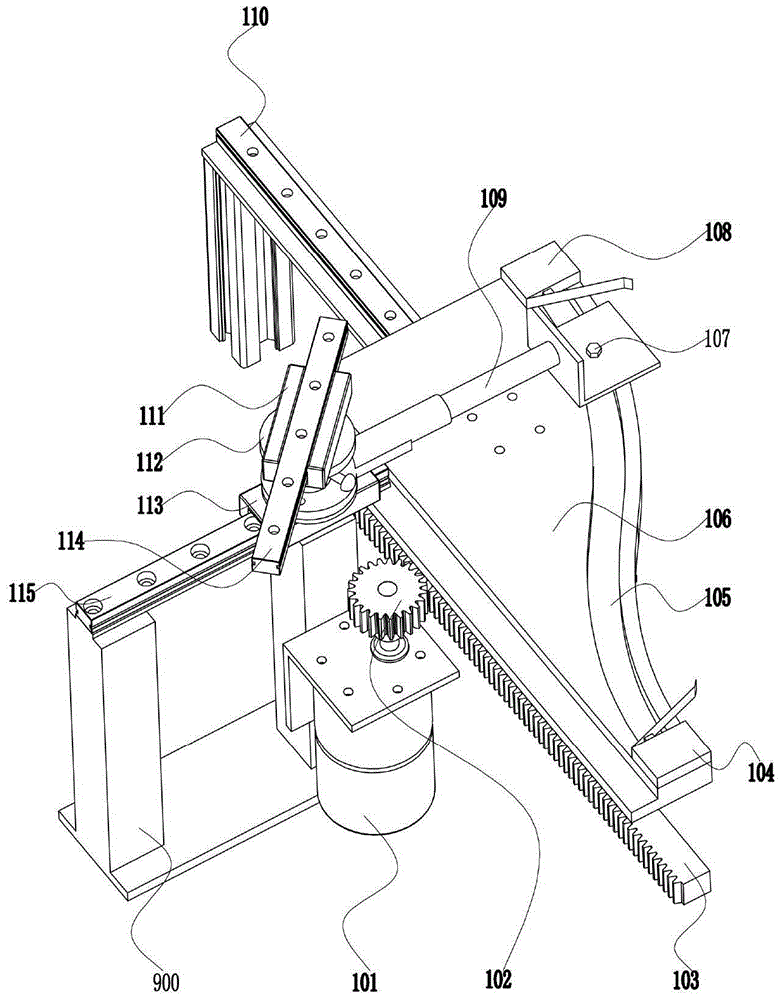

[0034] First, determine the follower 810 stroke 813h, base circle radius 807r, eccentricity 806e, and push angle 801φ 1 , Far angle of repose 802φ 2 , return angle 803φ 3 , Near angle of repose 805φ 4 The base circle radius 807 of the cam is adjusted by the base circle screw nut mechanism 607, the eccentric distance screw nut mechanism 604 adjusts the eccentricity 806, the stroke 813 is regulated by the stroke adjustment dial 112, and the prompt by the display screen 702 is followed by the numeric keypad 703 Type in the thrust angle 801φ 1 , Far angle of repose 802φ 2 , return angle 803φ 3 , Near angle of repose 805φ 4 , press the "*" key to confirm the input, press the "#" key to cancel the current operation, and A on the keyboard corresponds to the constant acceleration and deceleration curves. At this time, the display screen 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com