A bottom cold end spraying equipment

A technology of spraying equipment and cold end, which is applied in the direction of coating, spray booth, spraying device, etc. It can solve the problems of spraying dead angle, incomplete protective film, and asynchronous distance adjustment, etc., to achieve cost saving, uniform spraying without dead angle, and increase smoothness The effect of degree and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

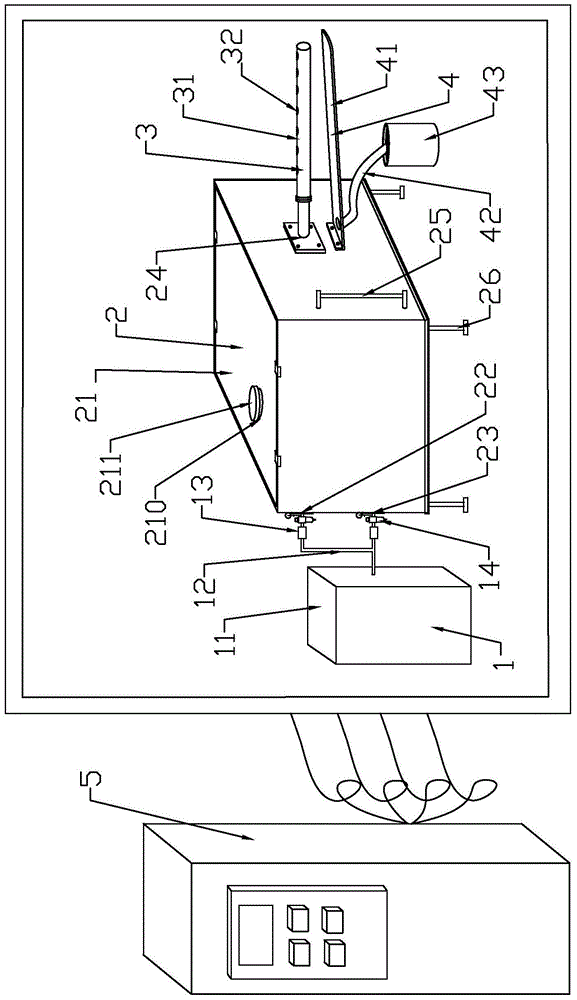

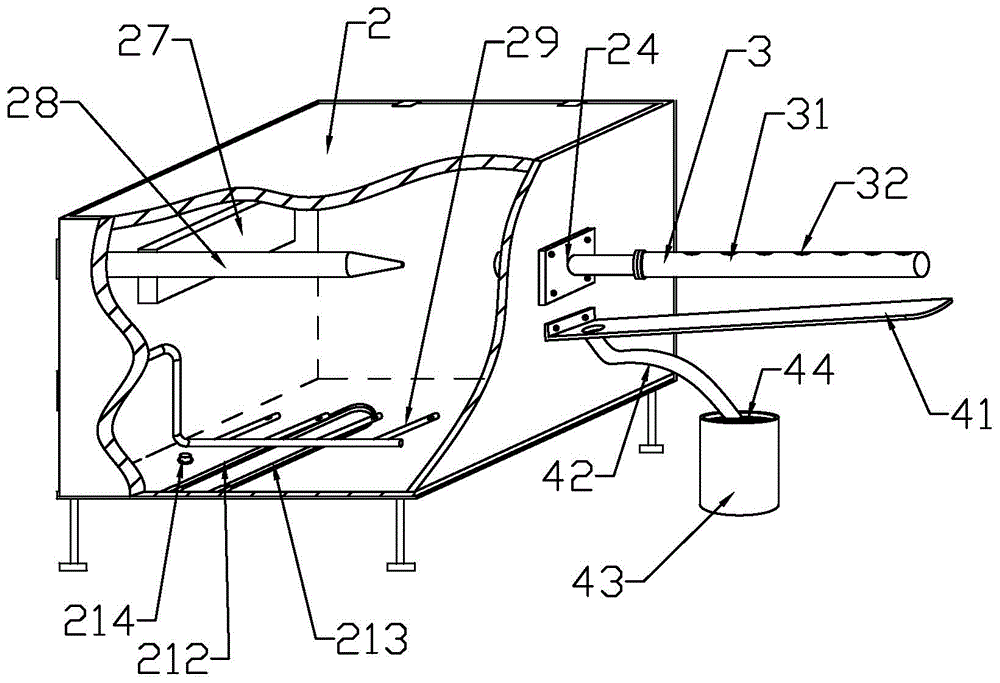

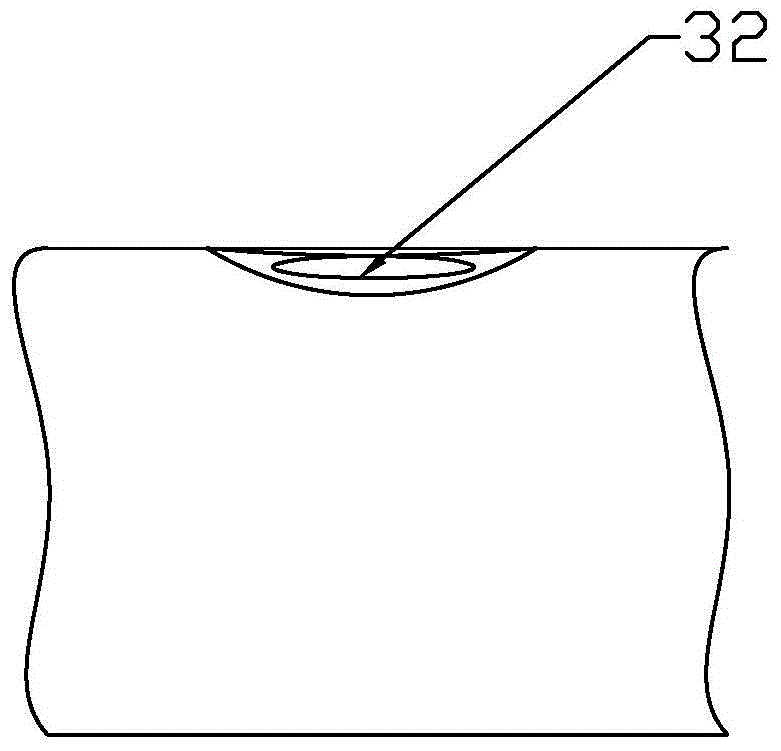

[0032] A bottom cold end spraying equipment, comprising an air supply system 1, an atomization system 2, a mist output system 3 and a material saving recovery system 4; the atomization system includes a tank body 21, a bracket 26, a temperature control heating device 212, a bottom Spray device 29, upper end diversion spray gun 28, described temperature control heating device 212, bottom spray device 29, upper end diversion spray gun 28 are all arranged in the inside of tank body 21; Described tank body 21 is a sealed tank body, tank body 21 The top is provided with a feeding port 210 for adding spraying liquid, an upper air inlet 22, a lower air inlet 23, a mist discharge port 24 and a liquid level gauge 25; the feeding port 210 is provided with a sealing cover 211, and the upper end guide The flow spray gun 28 is connected to the air supply system 1 through the upper air inlet 22, the air supply system 1 is located outside the tank body 21, the spray direction of the nozzle of...

Embodiment 2

[0038] A bottom cold end spraying equipment, comprising an air supply system 1, an atomization system 2, a mist output system 3 and a material saving recovery system 4; the atomization system includes a tank body 21, a bracket 26, a temperature control heating device 212, a bottom Spray device 29, upper end diversion spray gun 28, described temperature control heating device 212, bottom spray device 29, upper end diversion spray gun 28 are all arranged in the inside of tank body 21; Described tank body 21 is a sealed tank body, tank body 21 The top is provided with a feeding port 210 for adding spraying liquid, an upper air inlet 22, a lower air inlet 23, a mist discharge port 24 and a liquid level gauge 25; the feeding port 210 is provided with a sealing cover 211, and the upper end guide The flow spray gun 28 is connected to the air supply system 1 through the upper air inlet 22, the air supply system 1 is located outside the tank body 21, the spray direction of the nozzle of...

Embodiment 3

[0045] A bottom cold end spraying equipment, comprising an air supply system 1, an atomization system 2, a mist output system 3 and a material saving recovery system 4; the atomization system includes a tank body 21, a bracket 26, a temperature control heating device 212, a bottom Spray device 29, upper end diversion spray gun 28, described temperature control heating device 212, bottom spray device 29, upper end diversion spray gun 28 are all arranged in the inside of tank body 21; Described tank body 21 is a sealed tank body, tank body 21 The top is provided with a feeding port 210 for adding spraying liquid, an upper air inlet 22, a lower air inlet 23, a mist discharge port 24 and a liquid level gauge 25; the feeding port 210 is provided with a sealing cover 211, and the upper end guide The flow spray gun 28 is connected to the air supply system 1 through the upper air inlet 22, the air supply system 1 is located outside the tank body 21, the spray direction of the nozzle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com