Stamping device used for forming spike heads

A punching device and head technology, which is applied in the field of punching devices for forming the head of a spike, can solve the problems of high punching force, damage to the head of the spike, and low quality of the forming of the spike, so as to improve the quality of the spike. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

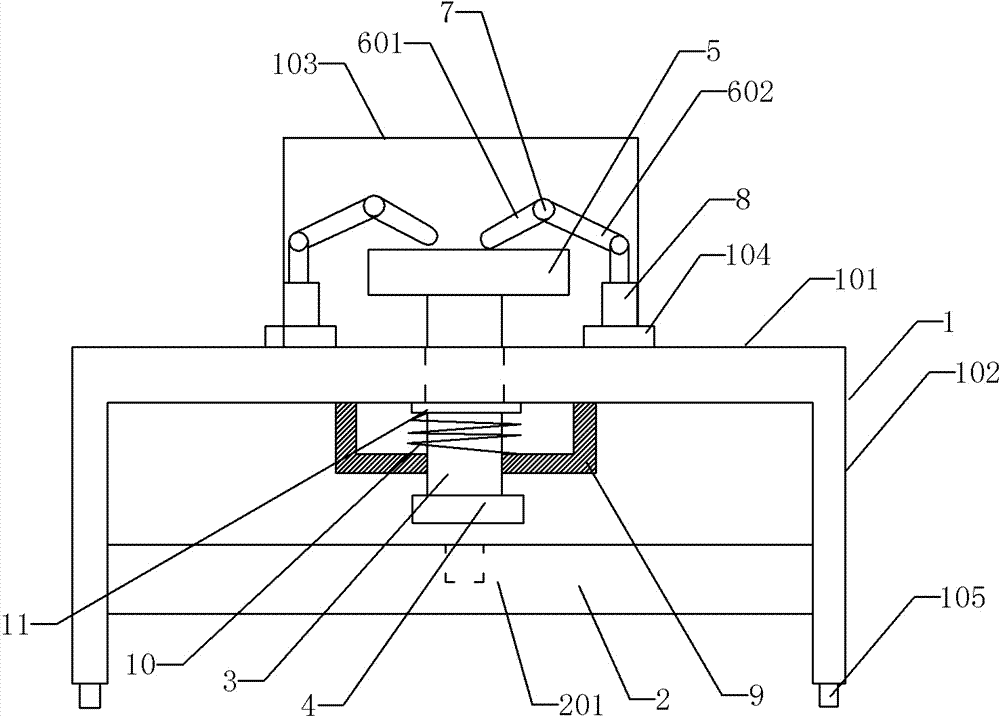

[0013] Such as figure 1 The stamping device shown for forming the head of the spike includes a base 1, a support table 101, a foot 102, a boss 103, a bearing table 104, a universal wheel 105, a stamping table 2, a positioning groove 201, a stamping rod 3, Punch 4, end plate 5, V-shaped rod driven end 601, V-shaped rod driven end 602, two pin shafts 7, two cylinders 8, spring mounting seat 9, return spring 10 and gasket 11.

[0014] The base 1 includes a horizontal supporting platform 101 and two legs 102 arranged on both sides of the supporting platform, four universal wheels 105 are arranged symmetrically under the two supporting feet 102, the boss 103 is arranged on the upper part of the supporting platform 101, and is located at The supporting platform 101 is centered, and the carrying platform 104 is symmetrically arranged on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com