Automatic centering fixture for annular workpieces

An automatic centering, annular workpiece technology, applied in the direction of manufacturing tools, metal processing mechanical parts, clamping, etc., can solve the problem that the arc side of the annular workpiece cannot be well positioned, it is not easy to process the outer circle of the pipe fittings, and the wall thickness of the pipe fittings is not easy to be processed. Uniformity and other issues, to save production time, increase stability, facilitate accurate positioning and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a limitation to the present invention.

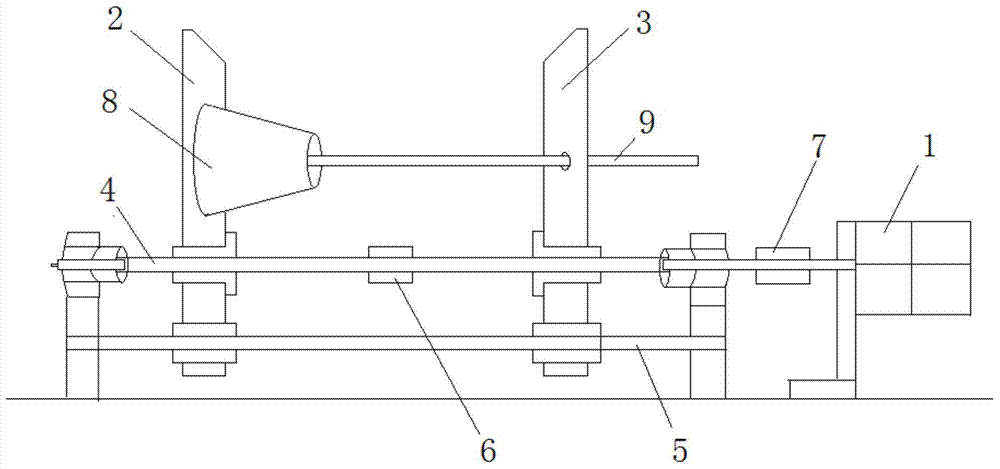

[0015] Such as figure 1 As shown, a self-centering fixture for a circular workpiece includes a bracket, a motor 1 screwed to the bracket, a first feed screw 4 screwed to the bracket through a second coupling 7, and the first feed screw 4. The second feed screw 5 parallel to the feed screw 4 is screwed to the first coupling 6 at the left and right ends of the first feed screw 4, and also includes a first guide plate 2 and a second guide plate 3; the first guide plate 2 and The lower end of the second guide plate 3 is respectively welded with two sliding seats, and the two sliding seats are respectively threaded with the first feed screw 4 and the second feed screw 5, and the first guide plate 2 is welded with a tapered tubular mandrel 8 and a long rod-shaped positioning post 9, the mandrel 8 is large on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com