Automatic packaging method

An automatic packaging and automatic technology, which is applied in the field of packaging materials, can solve the problems of low success rate of bag insertion, achieve the effect of avoiding interference, ordering the position, and improving the success rate of bag insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

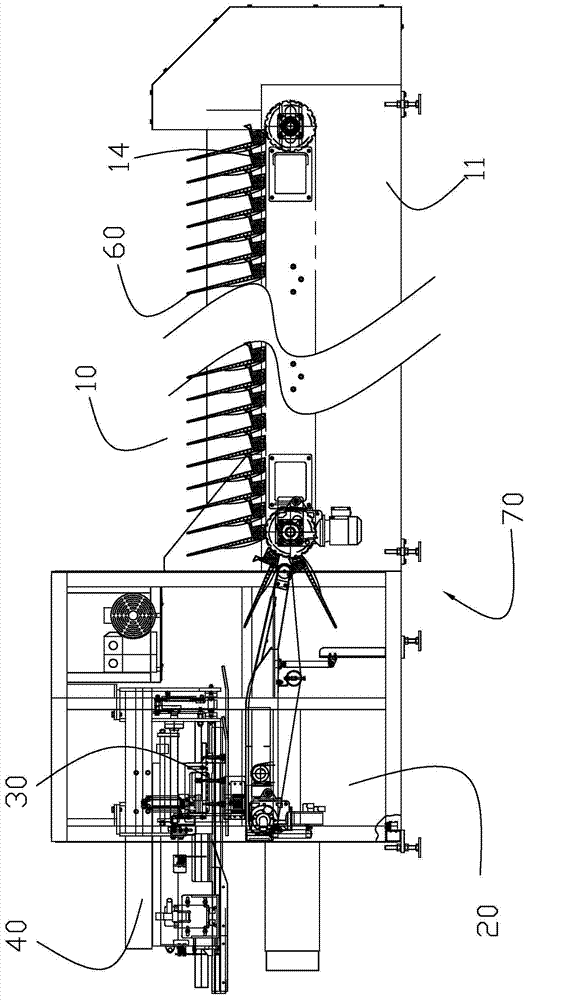

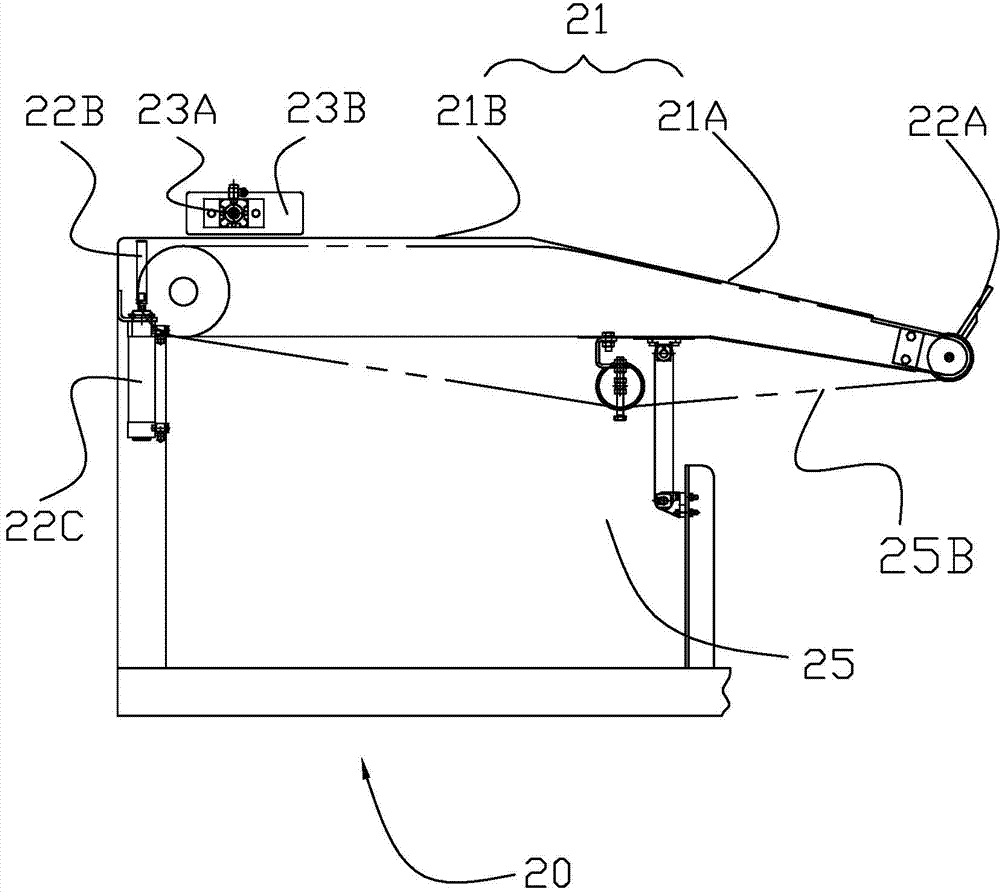

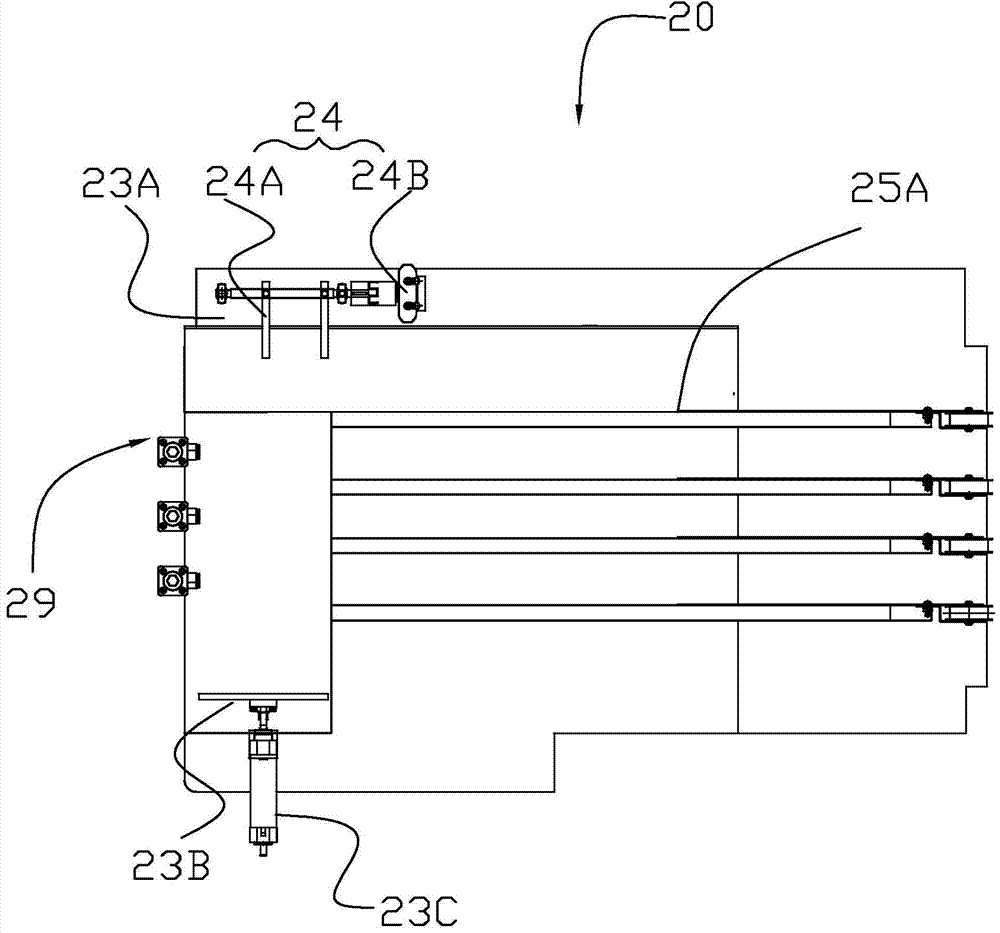

[0039] Such as figure 1 and Figure 18c As shown, a kind of automatic packaging method described in this embodiment, it utilizes automatic bag inserting machine 70 to automatically insert the valve port of packaging bag 60 on the discharge nozzle 50 of the packaging machine, so as to realize the packaging of the material to be packaged, the automatic The bag inserting machine 70 includes a bag feeding device 10, a bag carrying device 30, and a bag shooting device 40. The automatic bag inserting machine 70 also includes a finishing device 20, and the finishing device 20 includes a positioning device 29 and a bag pressing device 24. The automatic packaging The method includes the following steps: Step S1: the bag delivery device 10 transports the packaging bag 60 to the working platform 21, and the positioning device 29 positions the packaging bag 60 on the working platform 21 on a horizontal plane Step S2: the bag pressing device 24 presses the uppermost packaging bag 60 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com