Method for preparing porous graphene-like material from water hyacinth

A technology of water hyacinth and graphene is applied in the field of preparing porous graphene-like materials to achieve the effects of sufficient raw material sources, suitable for large-scale production and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Wash the discarded water hyacinth and dry it under vacuum at 80°C for 12 hours.

[0025] 2) Put the dried water hyacinth in 0.1mol / L HCl to acid boil for 1 hour, filter it with suction, and dry it in vacuum at 80°C for 12 hours;

[0026] 3) Put the water hyacinth after vacuum drying in N 2 In the atmosphere, the temperature is raised to 300°C at a rate of 1°C / min for pre-carbonization treatment for 1h;

[0027] 4) Mix the carbonized product after pre-carbonization in step 3) with KOH at a mass ratio of 1:8, and mix thoroughly in N 2 In the atmosphere, the temperature was raised to 400°C at a rate of 1°C / min for 1h, and then cooled to room temperature;

[0028] 5) Wash the sample obtained in step 4) with 0.1 mol / L HCl, then wash with distilled water several times until neutral, and dry the porous graphene-like material at 80°C.

Embodiment 2

[0029] Embodiment 2, with embodiment 1, difference is,

[0030] 2) Place the dried water hyacinth in 1mol / L HCl and acid boil for 3 hours, then suction filter;

[0031] 3) Put the water hyacinth after vacuum drying in N 2 In the atmosphere, pre-carbonize at a rate of 5°C / min at 500°C for 2 hours;

[0032] 4) Mix the carbonized product after pre-carbonization in step 3) with KOH at a mass ratio of 1:1, and mix thoroughly in N 2 In the atmosphere, the temperature was raised to 800°C at a rate of 5°C / min for 2 hours, and then cooled to room temperature;

[0033] 5) Wash the sample obtained in step 4) with 1mol / L HCl, then wash with distilled water several times until neutral, and dry the porous graphene-like material at 80°C.

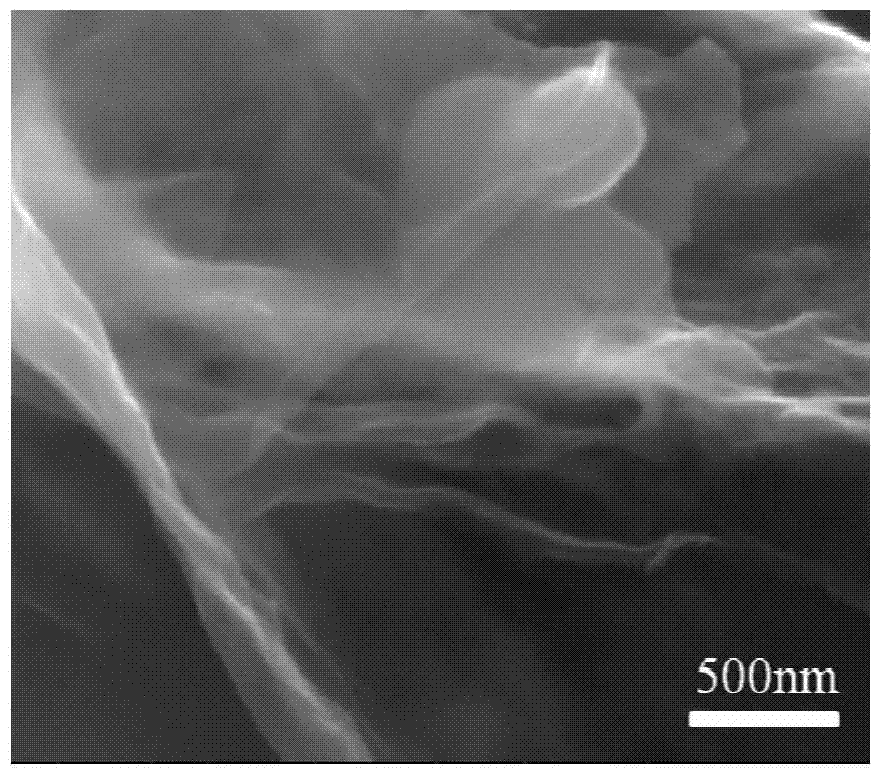

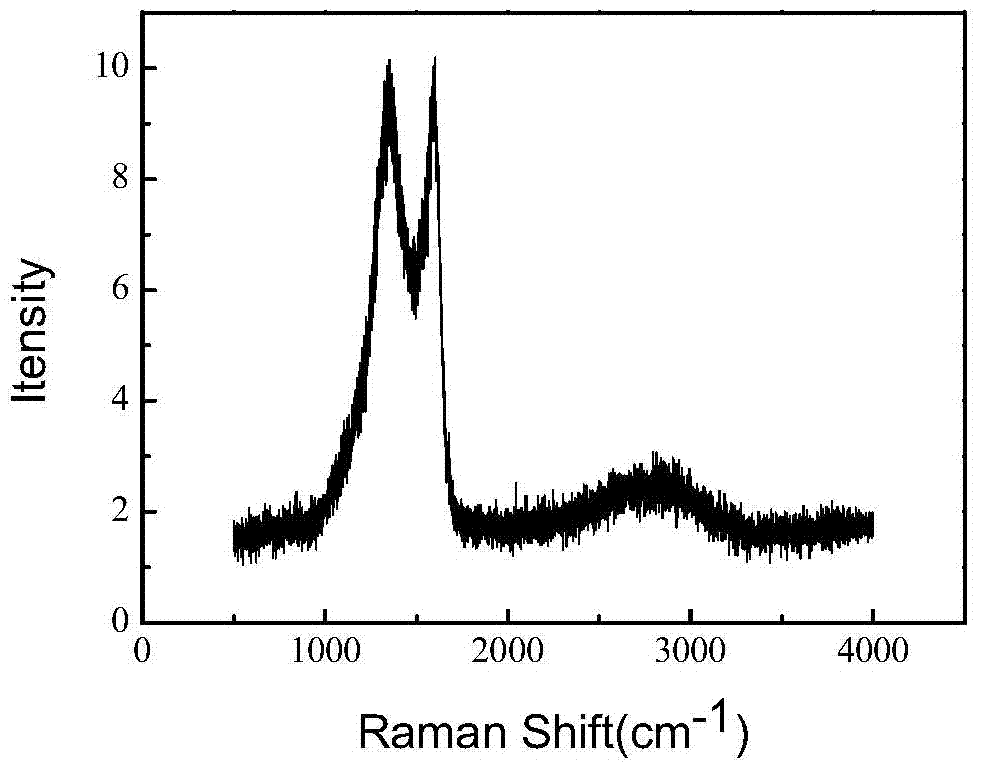

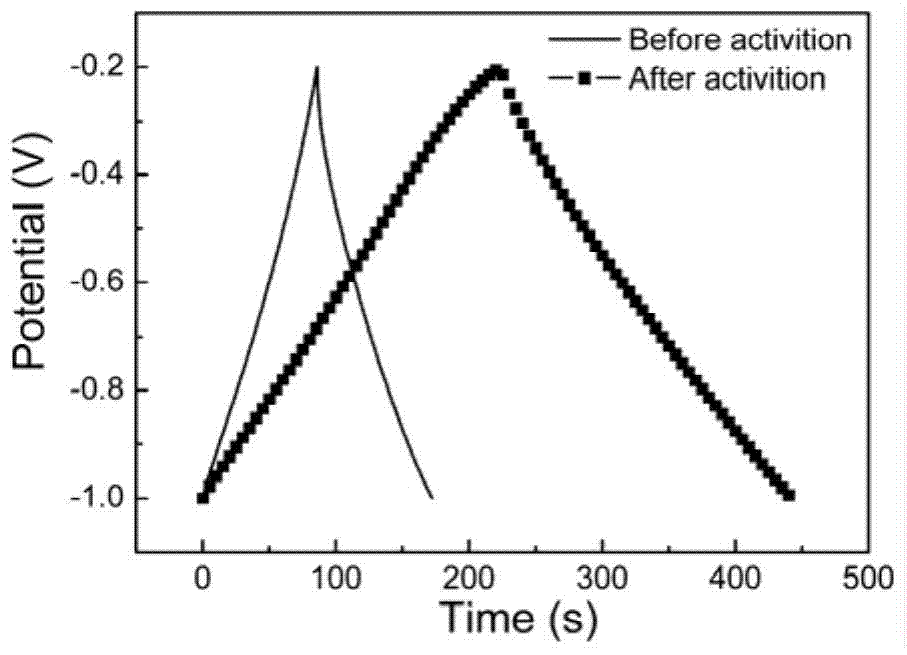

[0034] The porous graphene-like sheet prepared by this implementation consists of figure 1 The electron micrographs show that the product after high temperature treatment and activation is a lamellar structure. Depend on figure 2 According to the Ra...

Embodiment 3

[0035] Embodiment 3, with embodiment 1, difference is,

[0036] 2) Place the dried water hyacinth in 0.5 mol / L HCl and acid boil for 10 hours, then suction filter;

[0037] 3) Put the water hyacinth after vacuum drying in N 2 Pre-carbonization treatment at 800°C for 3 hours at a rate of 10°C / min in the atmosphere;

[0038] 4) Mix the carbonized product after pre-carbonization in step 3) with KOH at a mass ratio of 1:2, and mix thoroughly in N 2 In the atmosphere, the temperature was raised to 600°C at a rate of 6°C / min for 3 hours, and then cooled to room temperature;

[0039] 5) Wash the sample obtained in step 4) with 3mol / L HCl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com