Combined automatic doffing trolley

An automatic doffing and trolley technology, applied in textiles and papermaking, etc., can solve the problems of overhead empty bobbin box, empty bobbin cannot be transported smoothly, bobbin stuck, etc., to shorten time, improve function and use efficiency , the effect of saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

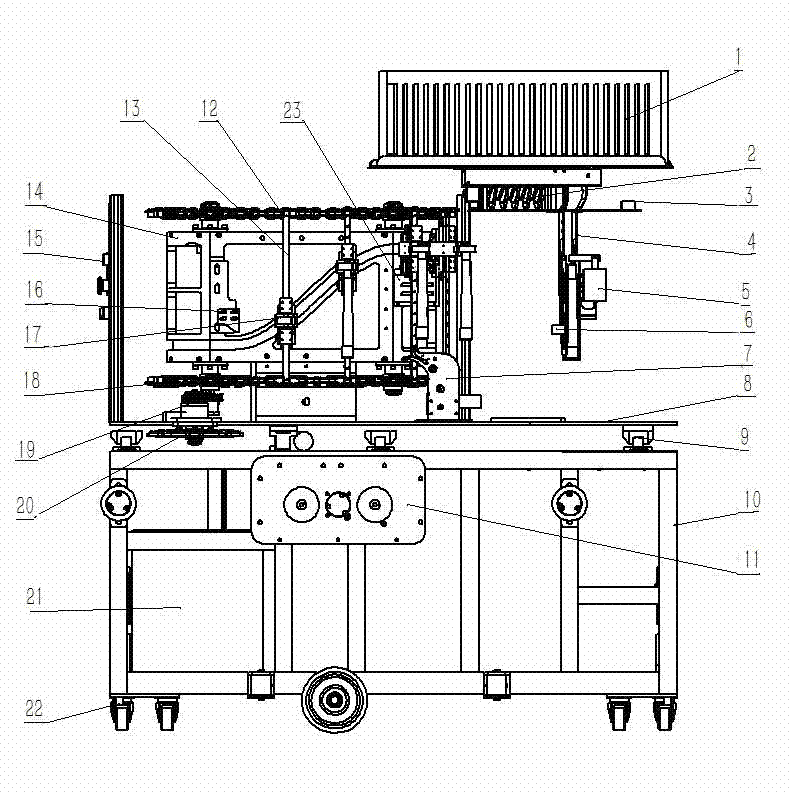

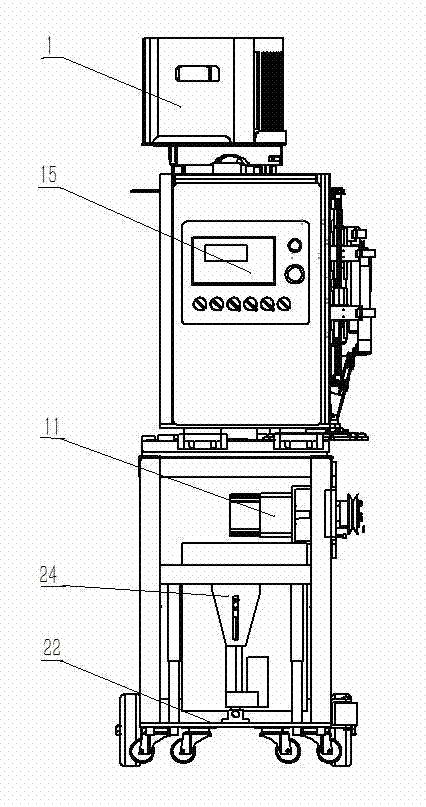

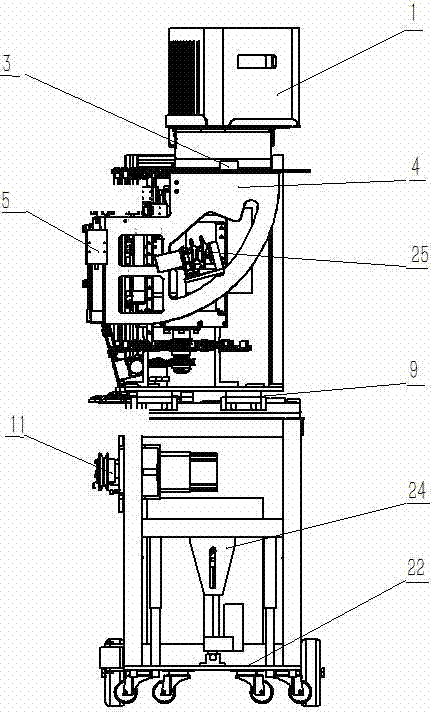

[0051] Such as Figure 1-4 Shown is the structural diagram of the combined automatic doffing trolley for distinguishing the bobbin size and vertically inserting the empty bobbin device, including the bobbin inserting device for distinguishing the bobbin big and small, the full bobbin pulling device, the traveling trolley device and the electric control system .

[0052] The bobbin inserting device for distinguishing bobbins from big to small includes an empty bobbin box 1, a first delivery screw driver 2, a bobbin position detection sensor 3, an empty bobbin channel 4, a bobbin insertion electromagnet 5, and a bobbin position detection sensor 6 and the second conveying screw driver 25, the empty bobbin box 1 is connected with the empty bobbin passage 4 through the first conveying screw driver 2, and the second conveying screw driver 25 is arranged in the middle of its empty bobbin passage 4 for The empty yarn bobbin is transported to the position of the yarn insertion bobbin,...

Embodiment 2

[0062] Figure 5 Shown is the device for distinguishing bobbins from big and small heads and inserting empty bobbins obliquely involved in the combined automatic doffing trolley of the present invention, including empty bobbin box 1, first conveying screw driver 2, bobbin position detection sensor 3 and empty bobbin tilting Intubation channel 26, the empty bobbin box 1 is connected with the inclined intubation channel 26 of the empty bobbin through the first conveying screw driver 2, and is used for the spindle rod to touch the lower end of the empty bobbin in the inclined intubation channel of the empty bobbin when the trolley is running At the edge of the hole, the empty yarn bobbin is pulled out of the inclined intubation channel and inserted on the spindle bar by its own weight in an inclined intubation mode. Other structures are the same as those in embodiment 1.

Embodiment 3

[0064] Figure 6-8 What is shown is the device for vertically inserting an empty bobbin regardless of the size of the bobbin, including the empty bobbin channel 4, the bobbin insertion electromagnet 5, the insertion position detection sensor 6, the second conveying screw driver 25, and the upper sprocket drive 42, The first bobbin distinguishing mechanism 43, the lifting chain 44, the lower sprocket drive 45, the empty bobbin box 46 that does not distinguish the bobbin size and the second bobbin distinguishing mechanism 47, the empty bobbin box that does not distinguish the bobbin small end 46 is provided with a lifting chain 44, the lifting chain 44 is connected to the upper sprocket drive 42 and the lower sprocket drive 45, and a second sprocket drive 42 is installed between the upper sprocket drive 42 and the empty bobbin case 46 that does not distinguish the size of the bobbins. The bobbin distinguishing mechanism 47, the back side of the second bobbin distinguishing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com