Grinder provided with compressing mechanism

A technology of pressing mechanism and grinding mechanism, applied in grinding machine tools, grinding devices, grinding workpiece supports, etc., can solve the problems of time-consuming and labor-intensive, poor labor protection effect, affecting product quality, etc., so as to improve the function and processing. Efficiency, Ease of Promotion and Application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

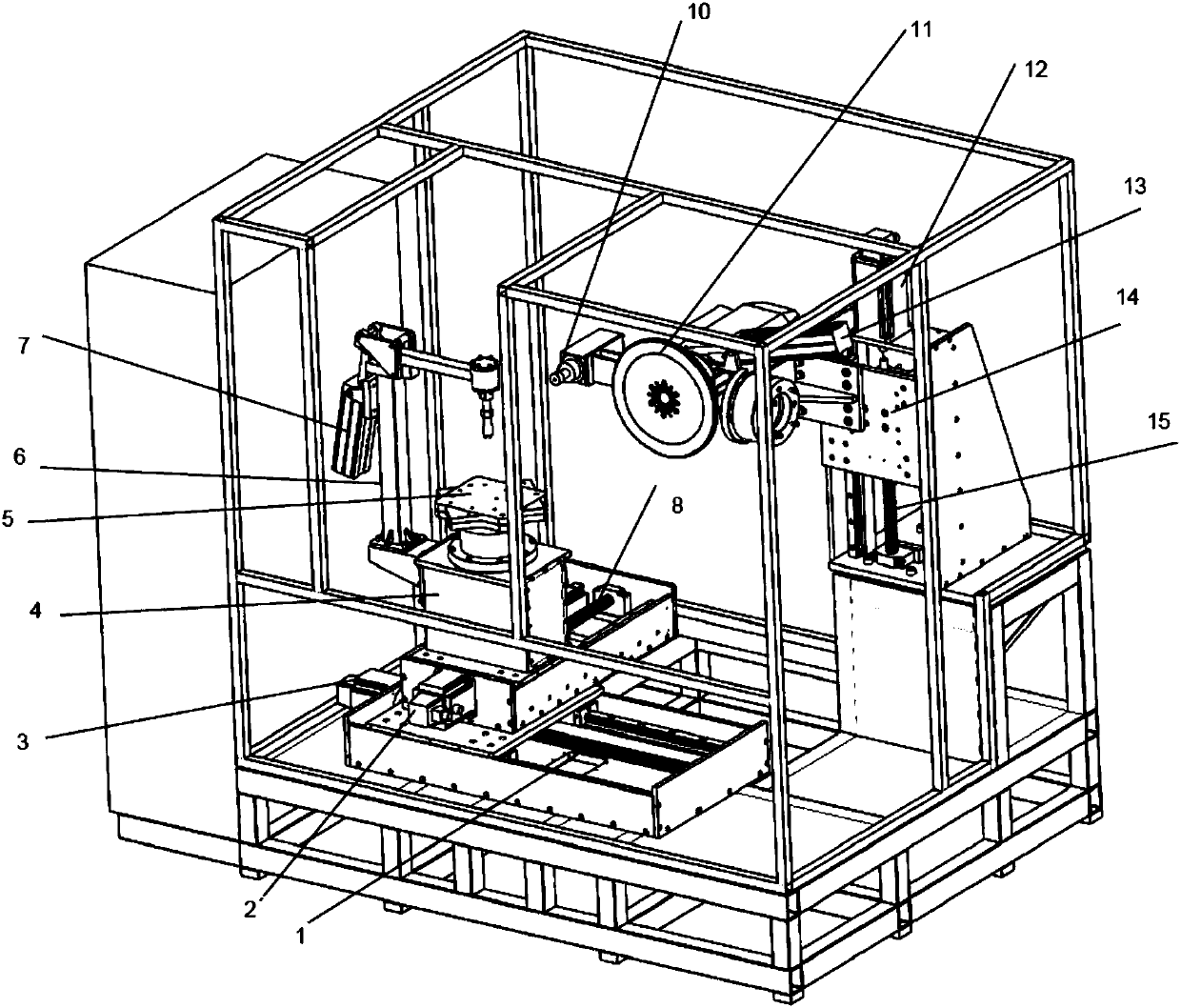

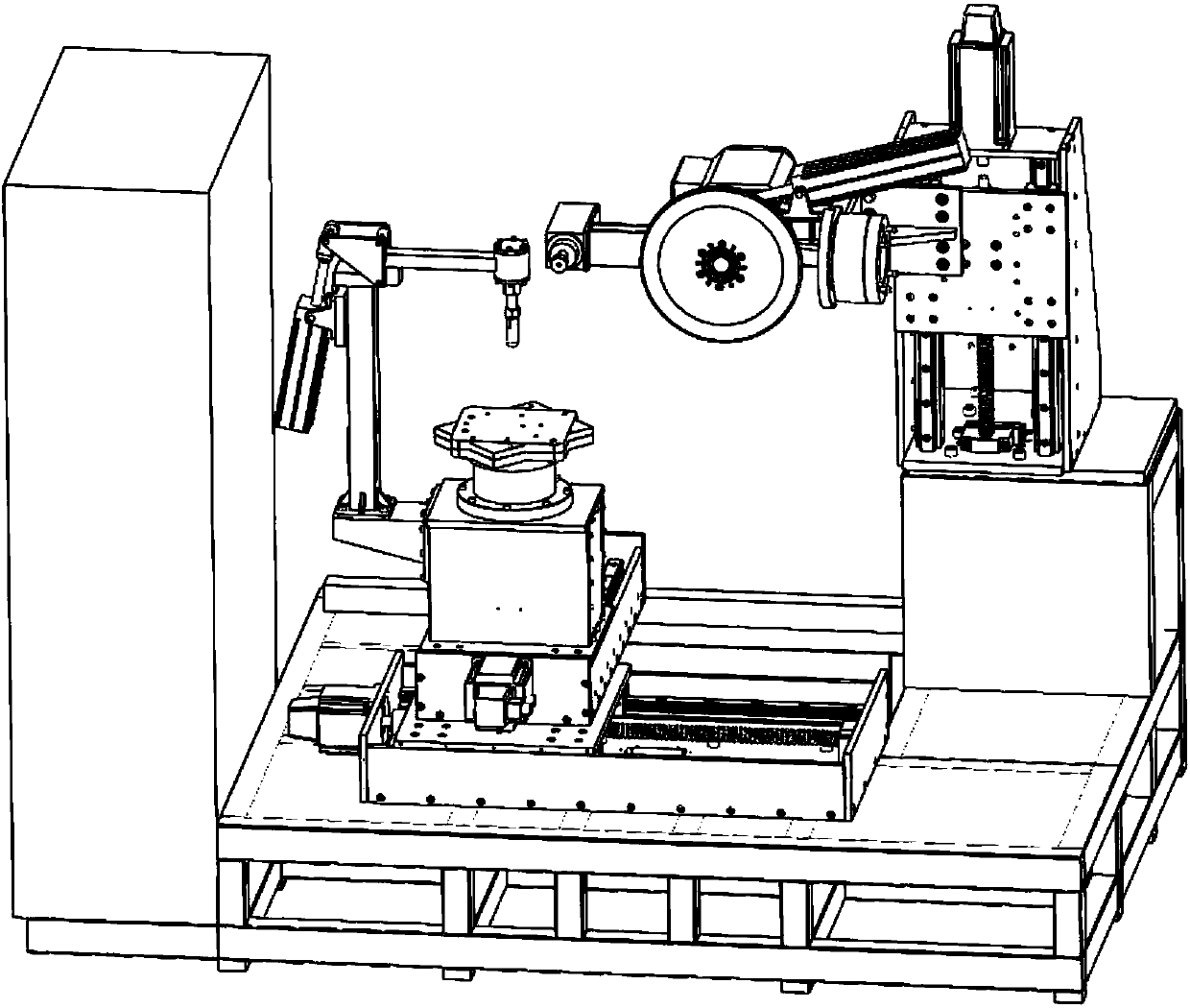

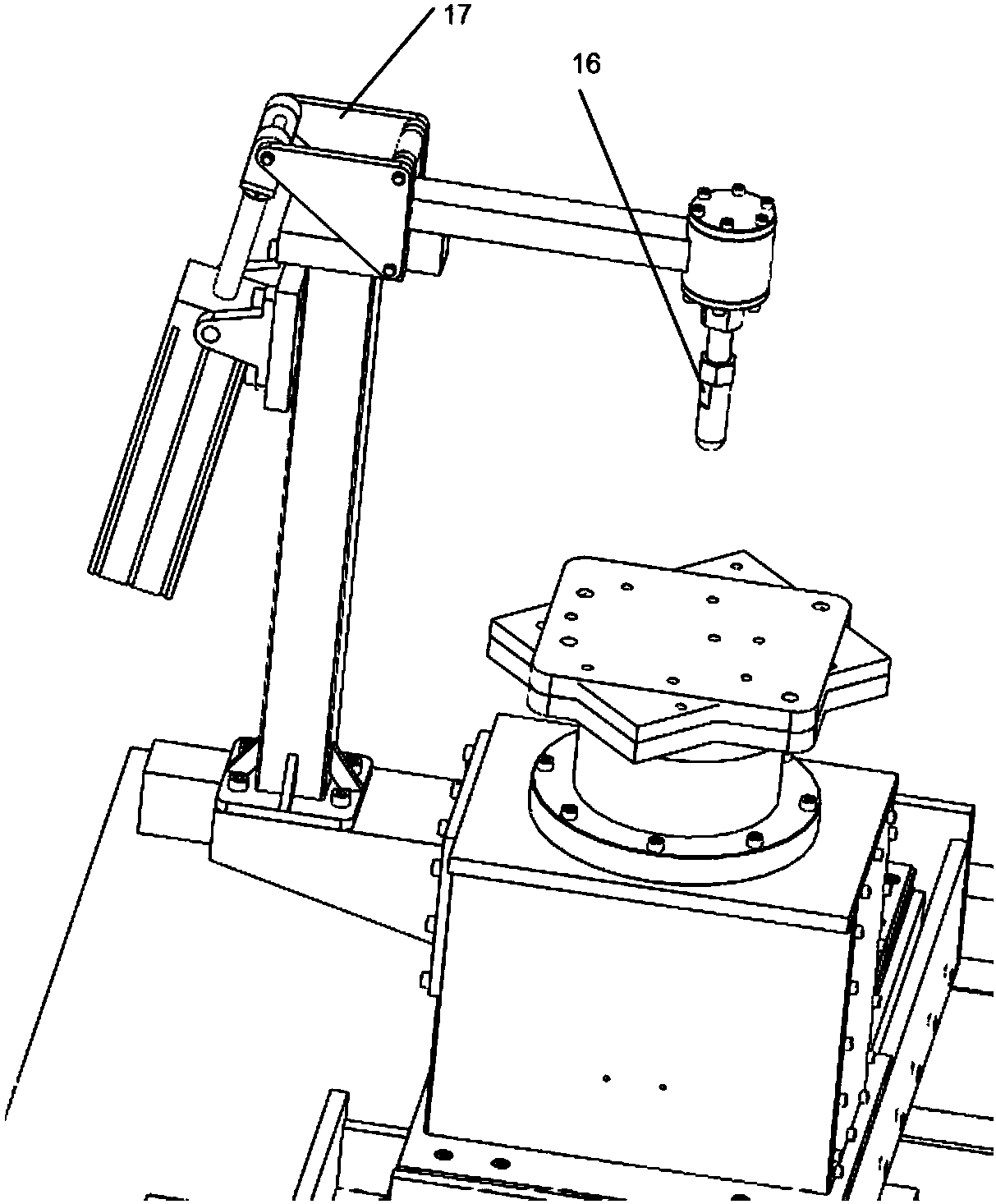

[0021] Such as Figure 1-9 As shown, this embodiment includes an X-axis drive mechanism, a Y-axis drive mechanism, a machine tool table, a grinding mechanism, and a cutting mechanism. The X-axis drive mechanism includes an X-axis drive motor 3, an X-axis ball screw 1, and the X-axis drive mechanism. The shaft driving motor 3 drives the X-axis ball screw to rotate, and the nut of the X-axis ball screw is connected with a Y-axis driving mechanism, and drives the Y-axis driving mechanism to move horizontally; the Y-axis driving mechanism includes a Y Shaft drive motor 2, Y-axis ball screw 8, the Y-axis drive motor 2 drives the Y-axis ball screw 8 to rotate, the nut of the Y-axis ball screw 8 is connected to the machine tool table 4, and the machine tool works The table 4 is connected with a tray 5, and the workpiece to be processed is placed on the tray 5; the grinding mechanism and the cutting mechanism are arranged on the machine tool support, and the grinding mechanism is conn...

Embodiment 2

[0024] Such as Figure 1-9 As shown, on the basis of Embodiment 1, in order to increase the accuracy of the operation and improve the work efficiency, a Z-axis drive mechanism is added. The grinding mechanism and the cutting mechanism are connected to the Z-axis drive mechanism through the grinding mechanism bracket. The Z-axis drive The mechanism includes a Z-axis drive motor 12, a Z-axis ball screw 15, and a lift plate 14. The Z-axis drive motor 12 drives the Z-axis ball screw 15 to rotate, and the nut of the Z-axis ball screw 15 and the lift plate 14, and the lifting plate 14 is connected with the grinding mechanism support.

[0025] Working process: The grinding mechanism and cutting mechanism can be driven up and down by the Z-axis driving mechanism, which increases the working angle of the grinding mechanism and cutting mechanism and improves the quality of work completion.

Embodiment 3

[0027] Such as Figure 1-9 As shown, on the basis of the above embodiment 1 or embodiment 2, the steering drive mechanism of the work platform is added, and the steering drive mechanism of the work platform includes a pallet rotation drive motor and a pallet 5 arranged in the machine tool table 4. The tray rotation driving motor is arranged vertically, which drives the tray to rotate.

[0028] Working process: The pallet is driven to rotate through the steering drive mechanism of the working platform, so that the workpiece to be processed can be rotated, and the workpiece to be processed can be processed on multiple sides, which makes the processing function of the equipment more powerful and can improve work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com