Nanometer rare-earth compound luminescent material and preparation method thereof

A technology of luminescent materials and nano-rare earths, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of unreasonable structure of rare earth industry, low overall product quality, and few varieties and specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

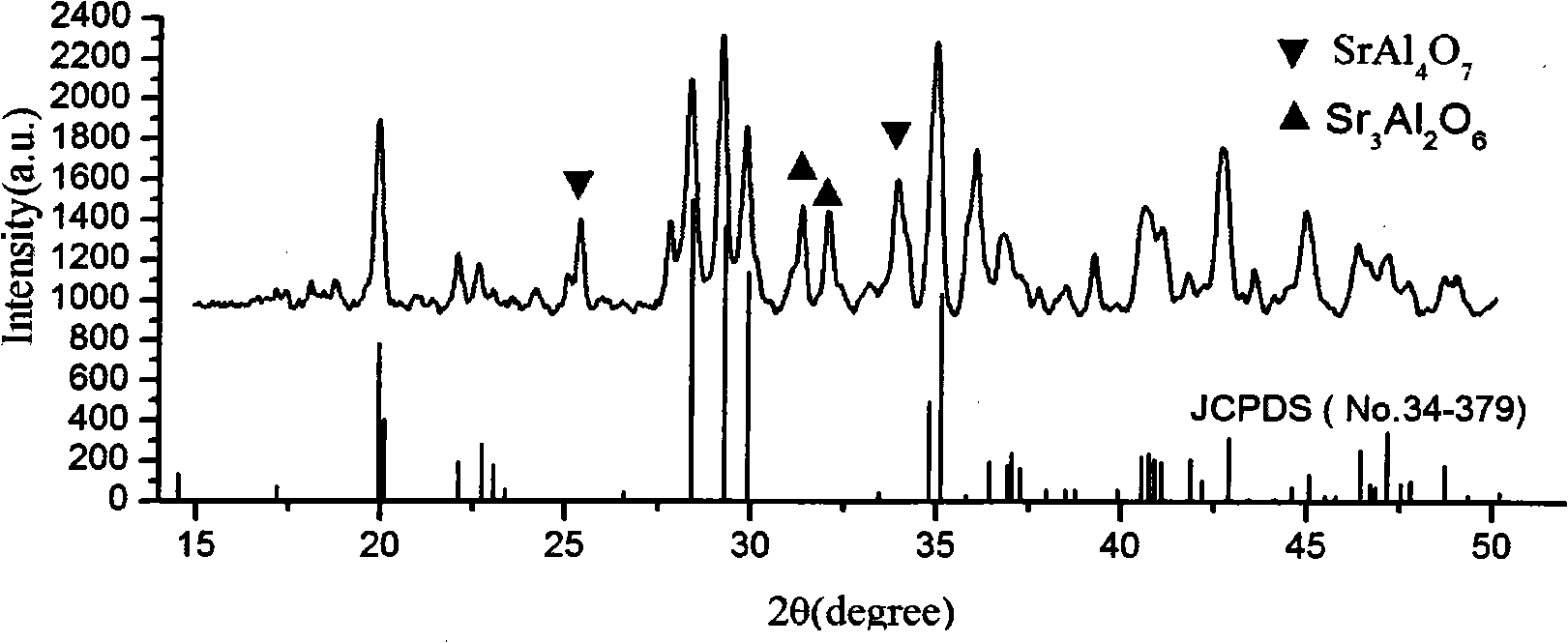

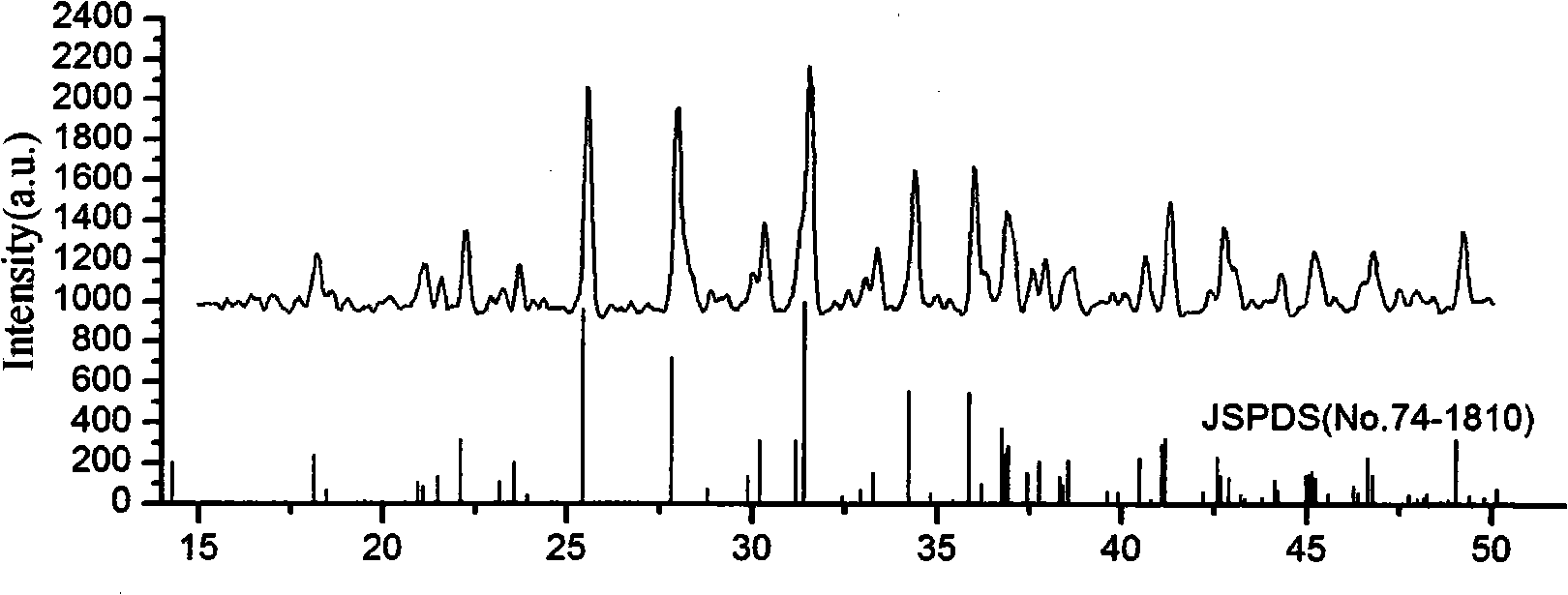

Image

Examples

Embodiment 1

[0017] Take 52.52 grams of Al(NO 3 ) 3 9H 2 O, 8.46 g Sr(NO 3 ) 2 Dissolve in distilled water in a 250ml beaker to obtain a clear solution; in addition, weigh 0.0352 grams of Eu according to the stoichiometric ratio 2 o 3 , 0.0373 g Dy 2 o 3 Put it into a 50ml beaker and dissolve it with concentrated nitric acid, combine the two solutions, and then add 3.7 grams of H 3 BO 3 and 100 g CO(NH 2 ) 2 , magnetically stirred in a constant temperature water bath at 70°C for 2 hours. After fully stirring, transfer the solution to a 300ml porcelain crucible and quickly put it into a muffle furnace that has been preheated to 500°C. As the reaction progresses, it can be observed that The solution rapidly boils, evaporates, expands, burns and releases a large amount of ammonia gas. The whole process is completed within 5 minutes. After cooling, it can be observed that the product is light yellow mushroom cloud, loose and porous, and can be finely ground after a little grinding. ...

Embodiment 2

[0019] Take 52.52 grams of Al(NO 3 ) 3 9H 2 O and 8.46 g Sr(NO 3 ) 2 Dissolve in distilled water in a 250ml beaker to obtain a clear solution; weigh another 0.044 grams of Eu 2 o 3 , 0.047 g Dy 2 o 3 Put it into a 50ml beaker and dissolve it with concentrated nitric acid, combine the two solutions, and then add 3.7 grams of H 3 BO 3 and 100 g CO(NH 2 ) 2, stirred magnetically in a constant temperature water bath at 70°C for 2 hours. After fully stirring, the solution was transferred to a 300ml porcelain crucible and quickly placed in a muffle furnace that had been preheated to 500°C. As the reaction progressed, it could be observed that The solution rapidly boils, evaporates, expands, burns and releases a large amount of ammonia gas. The whole process is completed within 5 minutes. After cooling, it can be observed that the product is light yellow mushroom cloud, loose and porous, and can be finely ground after a little grinding. Light yellow powder, put the product...

Embodiment 3

[0021] Take 52.52 grams of Al(NO 3 ) 3 9H 2 O and 8.46 g Sr(NO 3 ) 2 Dissolve in distilled water in a 250ml beaker to obtain a clear solution; weigh another 0.053 grams of Eu 2 o 3 , 0.056 g Dy 2 o 3 Put it into a 50ml beaker and dissolve it with concentrated nitric acid, combine the two solutions, and then add 3.7 grams of H 3 BO 3 and 100 g CO(NH 2 ) 2 , stirred magnetically in a constant temperature water bath at 70°C for 2 hours. After fully stirring, the solution was transferred to a 300ml porcelain crucible and quickly placed in a muffle furnace that had been preheated to 500°C. As the reaction progressed, it could be observed that The solution rapidly boils, evaporates, expands, burns and releases a large amount of ammonia gas. The whole process is completed within 5 minutes. After cooling, it can be observed that the product is light yellow mushroom cloud, loose and porous, and can be finely ground after a little grinding. Light yellow powder, put the produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com