A tent pole structure

A pole structure and tent frame technology, which is applied in the field of tents, can solve the problems of increasing manufacturing costs, increasing the weight of the tent frame, and numerous poles, etc., and achieve the effects of increasing service life, reducing manufacturing costs, and reducing repair rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

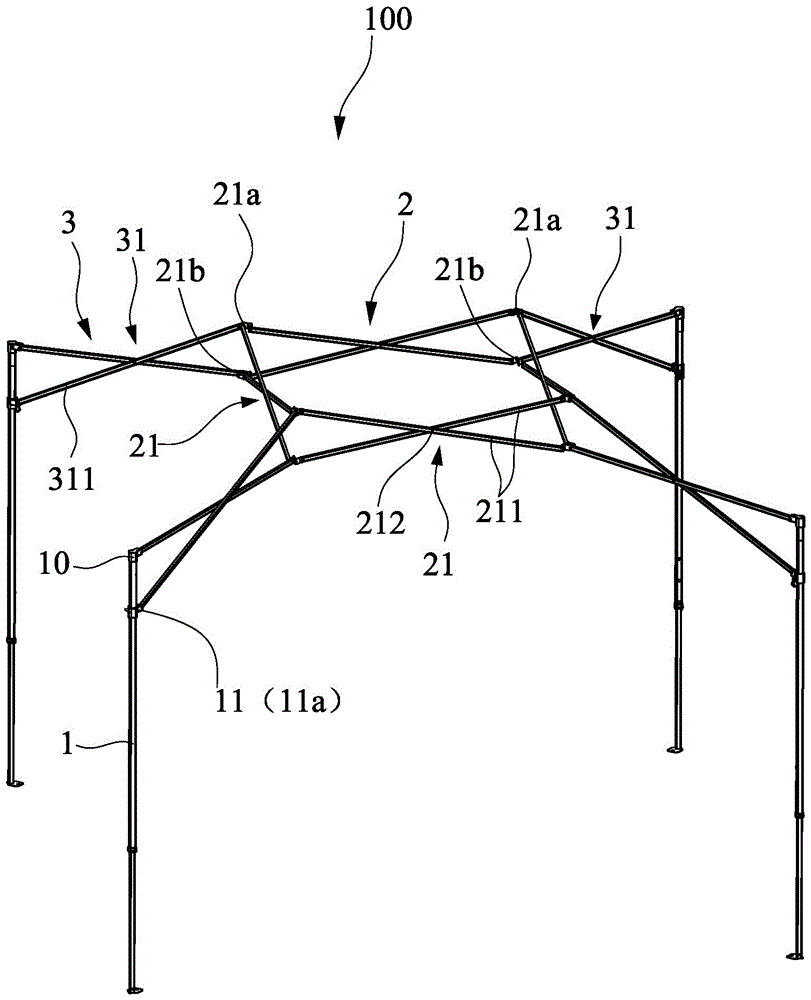

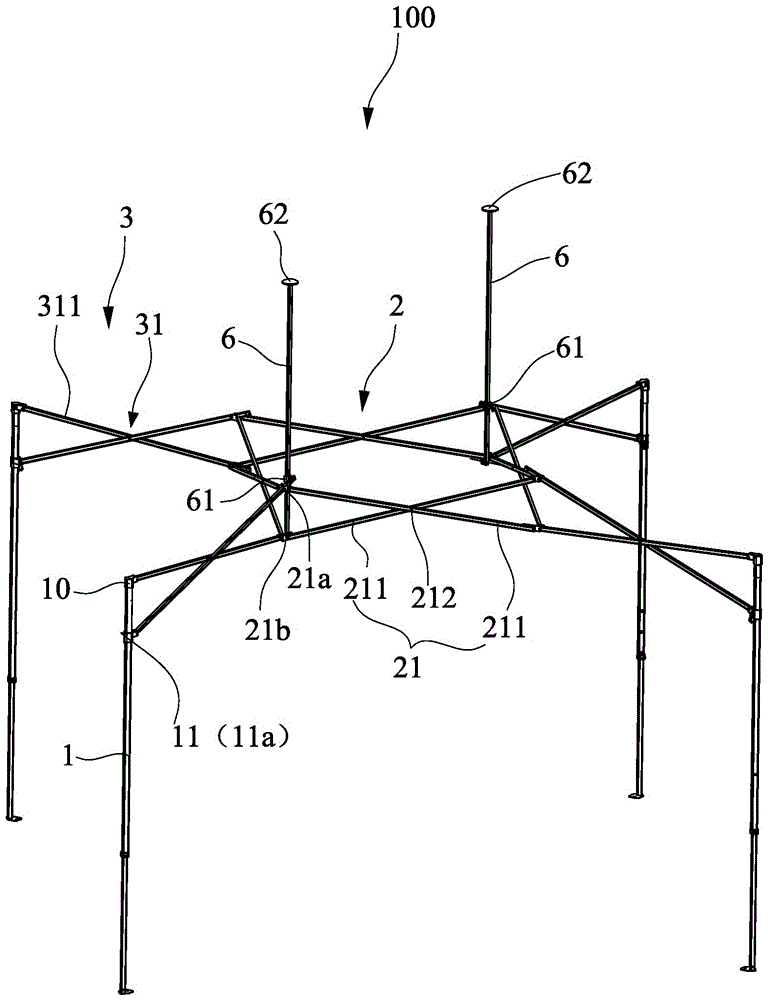

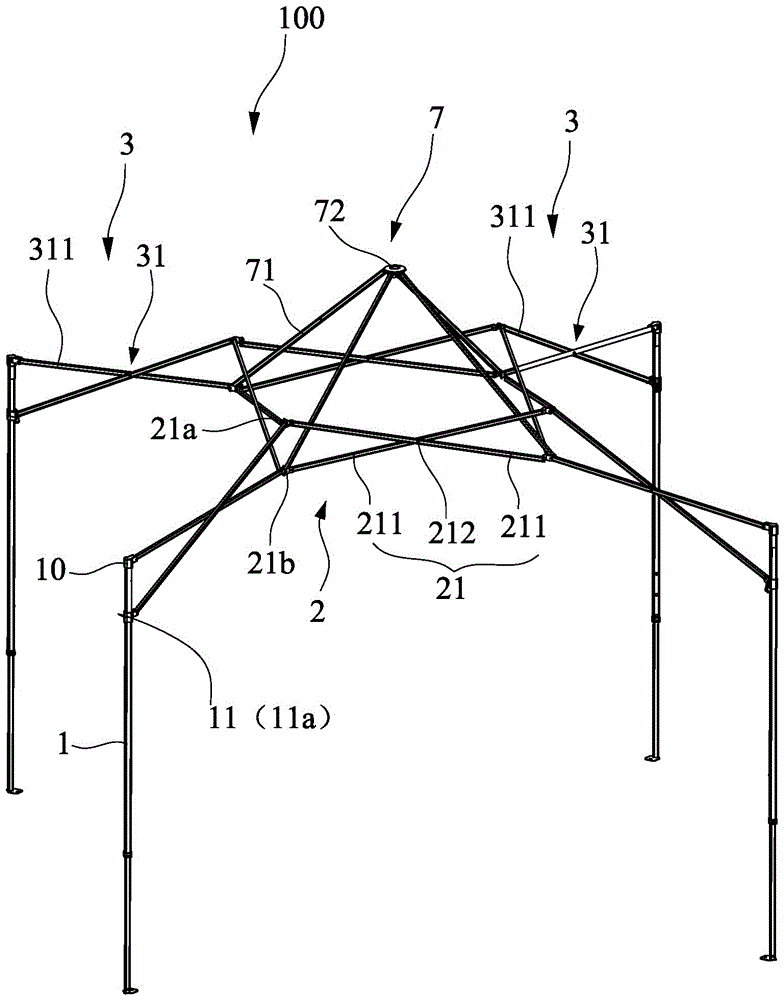

[0042] figure 1 It is the first preferred embodiment of the present invention. As shown in the figure, a tent pole structure 100 of the present invention includes four vertical poles 1, roof brackets 2 and supporting push rod groups 3, vertical poles 1 and roof brackets 2 They all directly contact with the tent cloth (not shown in the figure) and form support for the tent cloth. Of course, the number of poles 1 can also be three, five or more, which can be selected according to actual needs. The pole 1 is a telescopic pole, and the support rod group 3 is used to connect the roof support 2 and the pole 1 .

[0043] Such as figure 1 As shown, the unfolded pole 1 is placed vertically, and of course it can also be arranged to be placed at a predetermined inclination with the ground according to needs. Sliding sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com