Clamping device for fixing

A technology of clamping device and fixing plate, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems of inconvenient operation, easy slipping of clamping, etc., and achieve the effect of avoiding falling off and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

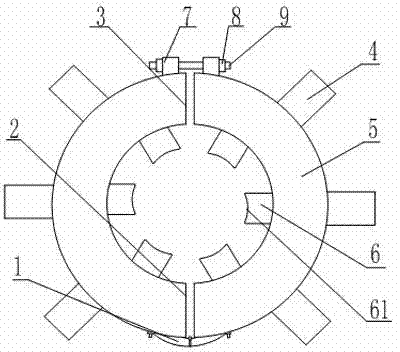

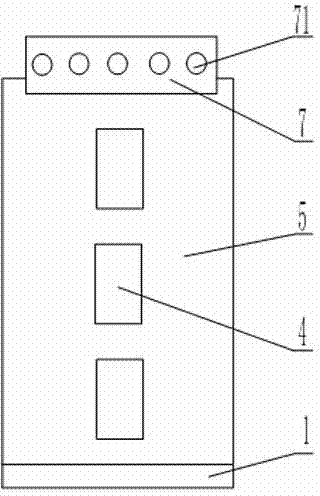

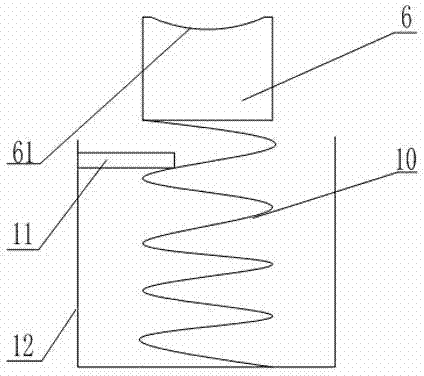

[0021] like Figure 1 to Figure 3 As shown, a clamping device for fixing includes a snap ring body, the outer wall of the snap ring body is provided with a fixed block 4, the snap ring body includes two symmetrically arranged snap rings 5, and the snap ring 5 is provided with an opening 3, a closed End 2, the closed ends of the two snap rings 5 are provided with a loose-leaf 1, and the openings 3 of the two snap rings 5 are welded with a fixed plate 7 cooperating with the screw rod 9 and the nut 8, and the fixed plate 7 is provided with several threaded through holes 71, 6 grooves 12 are provided in the clasp 5, and a reset mechanism 10 is arranged in the groove 12. The reset mechanism 10 is a spring, and a baffle plate 11 is arranged on the inner wall of the groove 12, and a clamping block 6 is arranged on the upper end of the spring. A clamping surface 61 is provided on the block 6, and the clamping surface 61 is recessed inward to form an arc surface, and the arc of the...

Embodiment 2

[0023] like figure 1 , figure 2 , Figure 4 As shown, a clamping device for fixing includes a snap ring body, the outer wall of the snap ring body is provided with a fixed block 4, the snap ring body includes two symmetrically arranged snap rings 5, and the snap ring 5 is provided with an opening 3, a closed End 2, the closed ends of the two snap rings 5 are provided with a loose-leaf 1, and the openings 3 of the two snap rings 5 are welded with a fixed plate 7 cooperating with the screw rod 9 and the nut 8, and the fixed plate 7 is provided with several threaded through holes 71, There are six grooves 12 in the clasp 5, and a reset mechanism 10 is arranged in the groove 12. The reset mechanism 10 is a piston structure, and a clamping block 6 is arranged at the upper end of the piston, and a clamping surface 61 is arranged on the clamping block 6. The clamping surface 61 is recessed inward to form an arc surface, and the arc of the arc surface matches the drill rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com