Cylindricity detection device of connecting rod hole

A technology for cylindricity and connecting rod holes, which is applied in the field of cylindricity detection devices for connecting rod holes, which can solve the problems of high proficiency requirements for processing personnel, inconvenient use, and single sampling points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

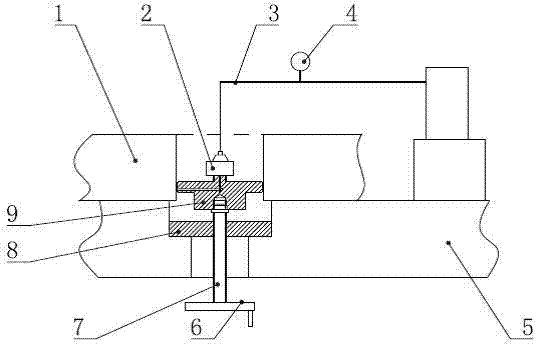

[0012] Embodiments of the present invention are as figure 1 As shown, the connecting rod hole cylindricity detection device includes: workpiece 1, nut 2, air guide tube 3, air pressure gauge 4, workbench 5, handle 6, screw rod 7, support block 8, and detection head 9.

[0013] Two axial and radial blind holes are processed on the detection head 9. The two blind holes are connected inside the detection head 9. The center line of the radial blind hole is perpendicular to the central axis of the detection head 9. The axis of the detection head 9 The stomata communicate with the trachea 3 .

[0014] Install the support block 8 in the round hole on the workbench 5, process a threaded hole concentric with the workbench hole on the support block 8, screw the screw rod 7 with the handle 6 at the end into the threaded hole of the support block 8 , the end of the screw rod 7 is threadedly connected with the detection head 9, the nut connected with the air duct 3 is threaded with the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com