Online monitoring and analysis device for energy efficiency of distribution transformer

A technology for distribution transformers and analysis devices, which is applied to measuring devices, electric power measurement through current/voltage, and measurement of electrical variables. It can solve the problems of high iron core material loss, heavy workload, and outdated equipment, and achieve low failure The effects of operation, refined management, and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

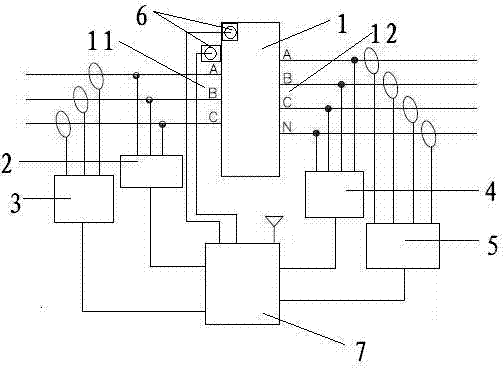

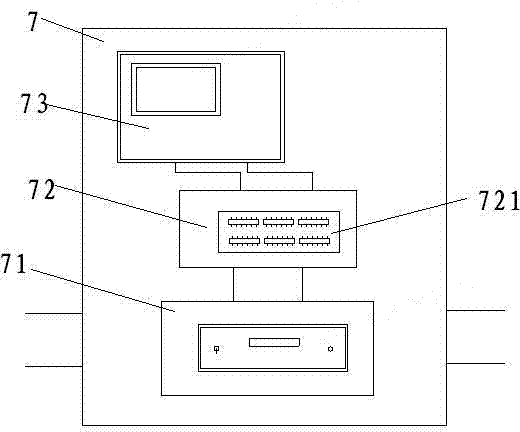

[0017] Such as figure 1 A distribution transformer energy efficiency online monitoring and analyzing device shown is characterized in that it includes a transformer 1, a primary side voltage sensor 2, a primary side current sensor 3, a secondary side voltage sensor 4, a secondary side current sensor 5, a temperature sensor 6 and Monitoring terminal 7, the transformer 1 includes a primary side 11 and a secondary side 12, the primary voltage sensor 2 and the primary current sensor 3 are installed on the primary side 11 of the transformer 1, the secondary voltage sensor 4 and The secondary current sensor 5 is installed on the secondary side 12 of the transformer 1, and the number of the temperature sensors 6 is two, which are respectively arranged in the transformer 1 and outside the transformer 1. The monitoring terminal 7 is connected to the primary voltage sensor 2, the primary The current sensor 3, the secondary voltage sensor 4, the secondary current sensor 5 and the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com