Photovoltaic controller calibration method and system

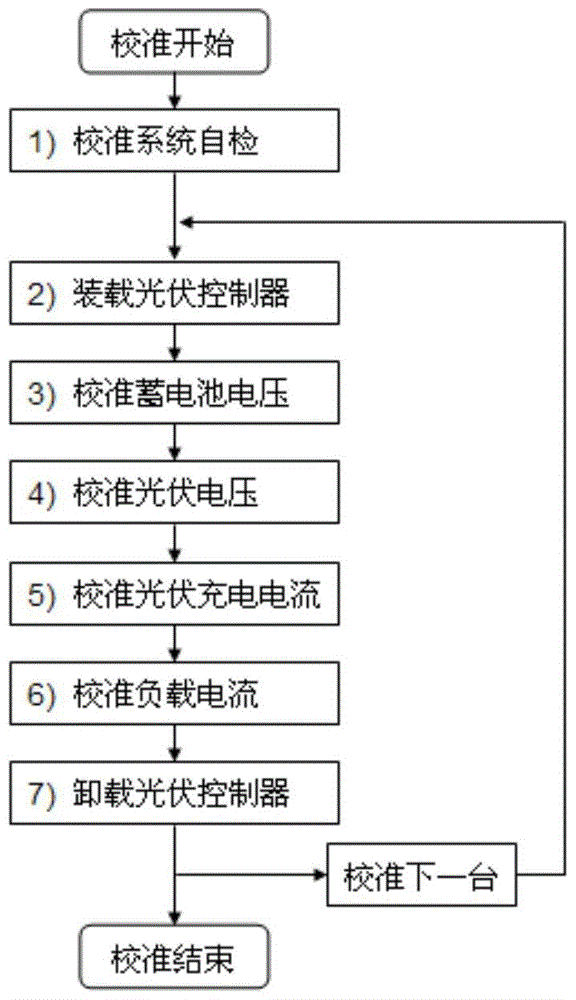

A photovoltaic controller and calibration system technology, which is applied in the field of solar photovoltaics, can solve problems such as large measurement errors, deviations in measurement values, and large measurement values, and achieve the effects of solving large error problems, improving calibration efficiency, and reducing calibration steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

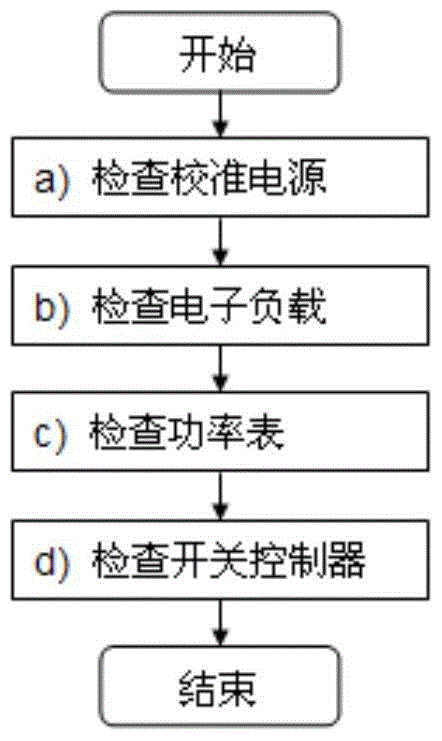

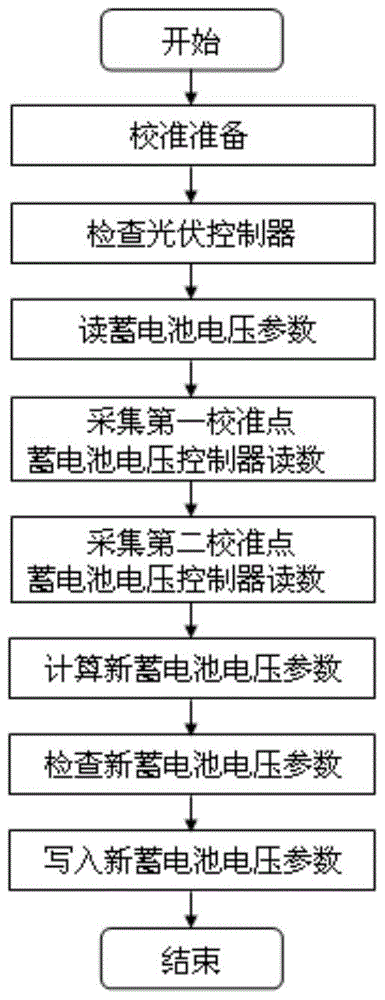

Method used

Image

Examples

Embodiment Construction

[0042] see Figure 17 The photovoltaic controller calibration system of the present invention consists of a computer 1, a calibration power supply 2, an auxiliary power supply 3, an electronic load 4, a standard power supply 5, a communicator 6, a power device 7, a switch controller 8, four relays 91, 92, 93, 94, diode 10 and cooling fan 11 form. The computer 1 is connected to the communicator 6, and the communicator 6 is also respectively connected to the calibration power supply 2, the electronic load 4, the power device 7 and the switch controller 8, the calibration power supply 2 is also connected to the corresponding relays 91, 92, and the power meter 7 is also connected to the Standard light source 5, switch controller 8 are connected with four relays 91, 92, 93, 94 respectively, diode 10 is connected with corresponding relay 93 and auxiliary power supply 3 respectively, cooling fan 11 is connected to Switch controller 8.

[0043] The computer 1 is equipped with a set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com