End cover for electric machine, electric machine and method for assembling electric machine

A technology of end caps and support elements, applied in the fields of end caps for motors, motors and for assembling motors, to achieve the effect of correcting asymmetry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

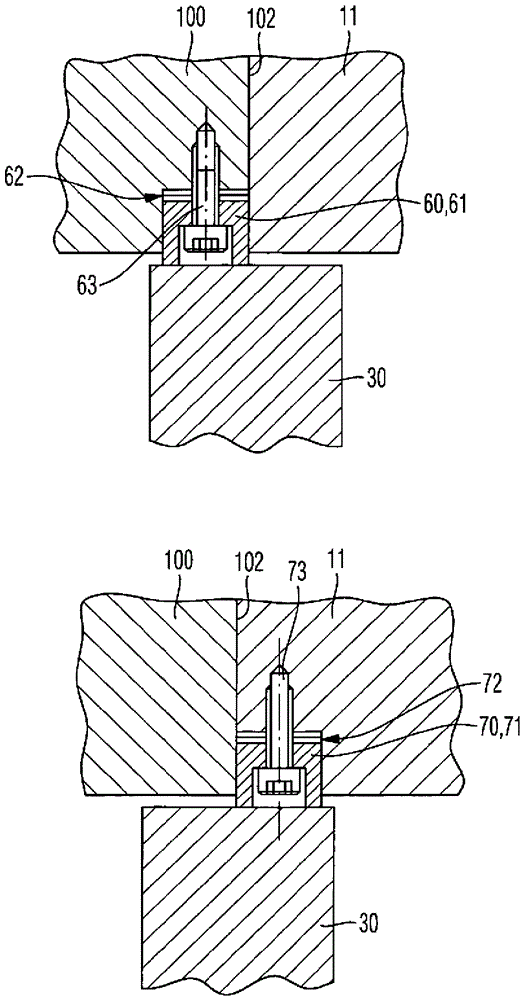

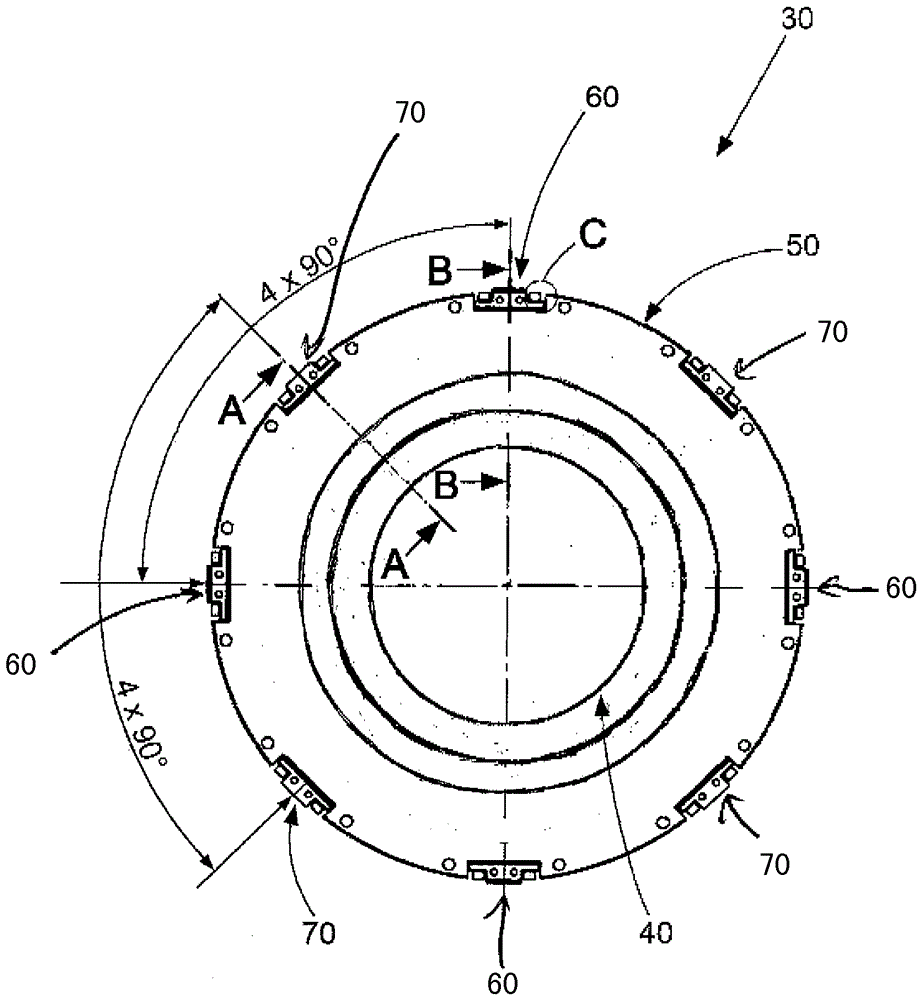

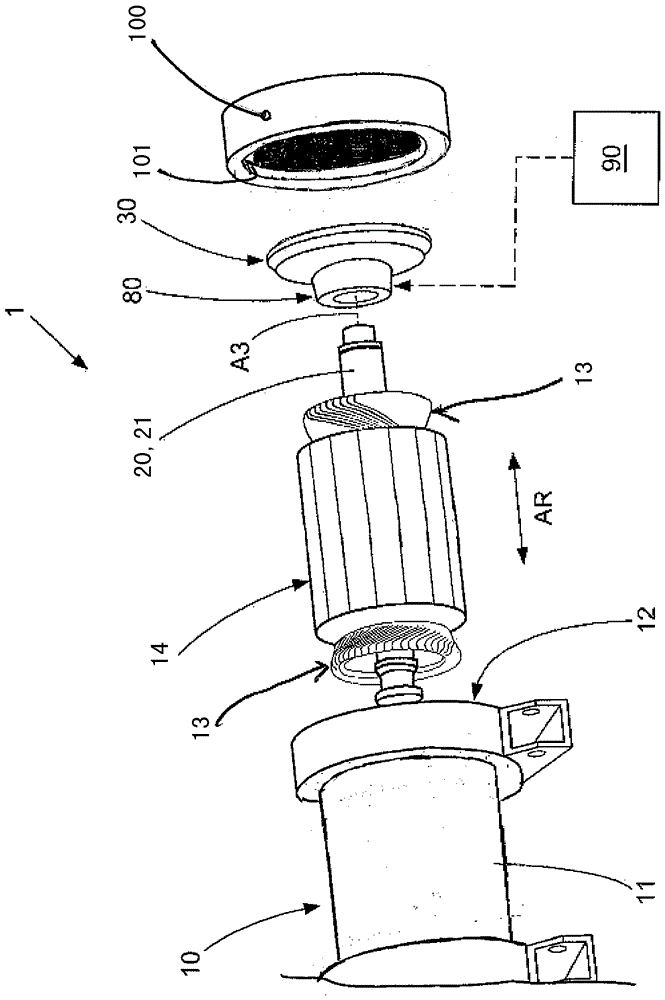

[0068] According to one embodiment of the invention, this is achieved by means of the following method steps performed successively:

[0069] By measuring the inner circumference 12 of the stator housing 11 (for example by means of a 3D coordinate measuring machine), the position of the geometrical longitudinal axis A2 of the inner circumference 12 of the stator housing 11 is determined. The outer circumference contour of the end shield 30 is fitted into the inner circumference 12 of the stator housing 11 in a roughly adjusted manner. To this end: by measuring the bearing receptacle 40 of the end shield 30 , the position of the center of the magnetic bearing 80 is determined relative to the position of the geometrical longitudinal axis A2 of the inner circumference 12 of the stator housing 11 . The value of the offset of the center of the magnetic bearing 80 relative to the geometrical longitudinal axis A2 of the inner circumference 12 of the stator housing 11 is then determin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com