Concentric ring-shaped clearance draft fan airflow nozzle

A technology of concentric rings and nozzles, applied in the direction of injection devices, injection devices, etc., can solve the problems of large fan air flow nozzles, no air flow, no mature technology, etc., and achieve long range, good blowing effect, and concentrated airflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment 1 Composition of a concentric annular gap nozzle of fan airflow and the effect of each component:

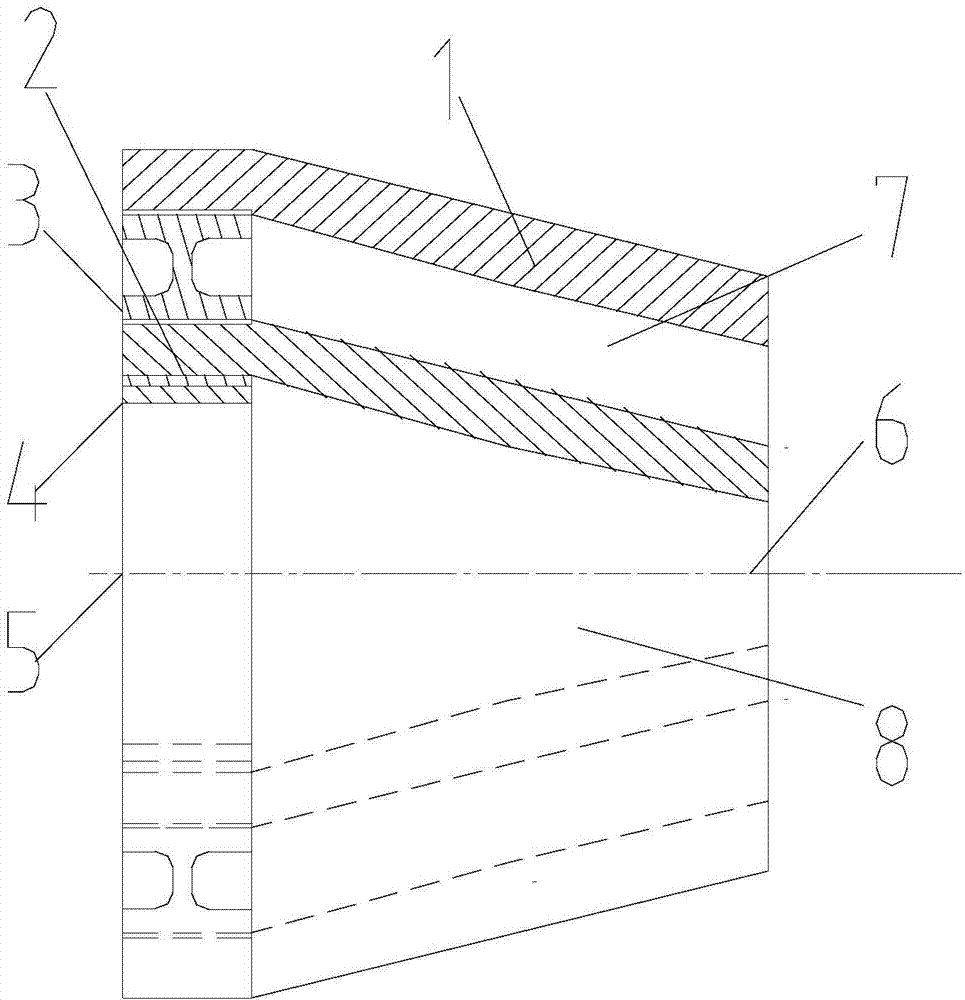

[0012] A concentric annular gap nozzle includes an outer nozzle 1, an inner nozzle 2, an inner and outer nozzle connector 3, an inner and outer nozzle connector middle circular gasket 4, a nozzle inlet 5, a nozzle outlet 6, and an outer nozzle cavity 7 . The inner nozzle cavity 8 is characterized in that the concentric annular gap nozzle is a double-layer hollow nozzle, and the size of the gap and the intercepted area of the cavity are adjusted by adjusting the number of circular gaskets 4 in the middle of the inner and outer nozzle connectors. The inclination angle of the nozzle is 15°. There are external threads and internal threads on the inner and outer nozzle connecting body 3, the external threads are used to connect the outer layer nozzle 1, and the internal threads are used to connect the inner layer nozzle 2, and are used to connect the nozzles and...

Embodiment 2

[0013] Embodiment 2 Working principle of a concentric annular gap nozzle for fan air flow:

[0014] The air flow of the fan enters from the nozzle inlet 5, and then passes through the outer nozzle cavity 7, the inner nozzle cavity 8, and the nozzle outlet 6, and the outer nozzle cavity 7, the inner nozzle cavity 8 from the nozzle inlet 5 to the nozzle outlet 6 The streamlined design minimizes the drag coefficient. After exiting from the nozzle outlet 6, the outer layer airflow suppresses the inner layer airflow to diffuse the airflow column, so the range is long and the impact is strong.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap