Liftable worktable

A work table and table stand technology, which can be applied to work tables, manufacturing tools, etc., can solve the problems of complicated operation, cumbersome equipment, and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention. All similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

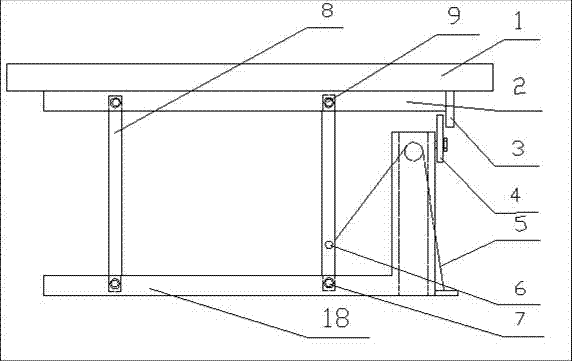

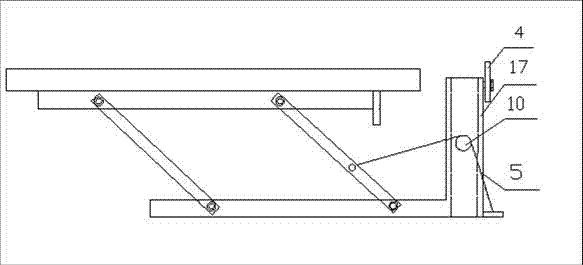

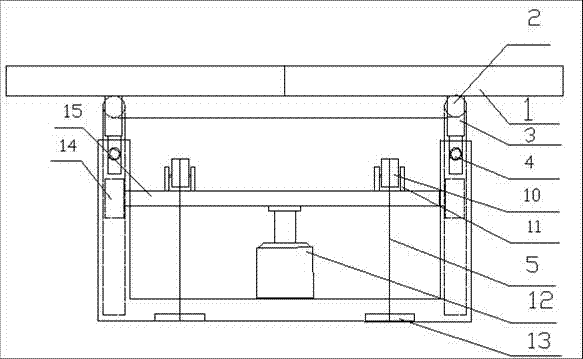

[0018] An elevating work table provided by the present invention includes a table frame and a table plate (1) fixed on the upper end of the table frame, and is characterized in that it also includes a hydraulic jack (12), a fixed pulley (10), and a rolling bearing (14) , steel wire rope (5), channel steel slideway (17), mobile crossbeam (15), fixed crossbeam (13), four table legs (8).

[0019] The lower part of the table frame is fixed with a rectangular fixed frame, which is composed of two parallel "L" shaped channel steels (18) welded with fixed beams (13), and the two "L" shaped channel steels ( 18) Two rotating shafts (7) are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com