Special low-floor hinging type rail vehicle for railroad car

A technology for trams and rail vehicles, applied in the field of municipal transportation, can solve problems such as space problems, and achieve the effects of good drivability, small wheels and track wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

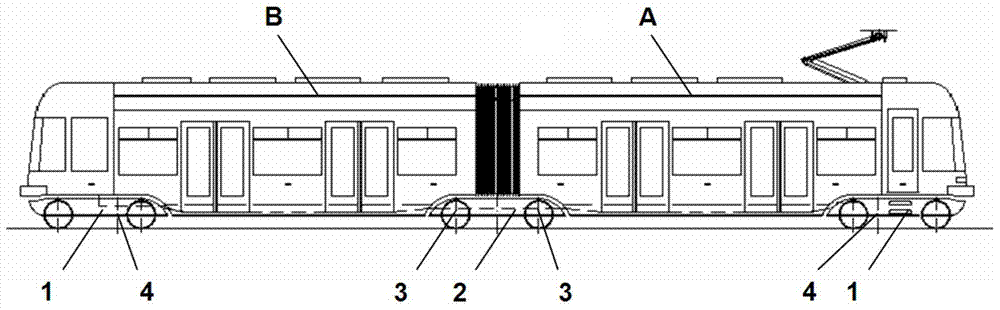

[0019] Such as image 3 The shown low-floor rail vehicle, in particular a tram, is arranged in a two-car configuration with sections A and B and three bogies.

[0020] Figure 4 The vehicle in is extended by a section and has four bogies.

[0021] shown in image 3 The articulated rail vehicle in is equipped with a first end rotatable bogie 1 under the front of section A and a second end bogie 1 under the rear of section B and at the hinge ( An intermediate bogie 2 under the link between sections A and B of the vehicle, while both adjacent ends of the body (sections A and B of the vehicle) are rotatably mounted on the intermediate bogie , each located in separate mounting points 3.

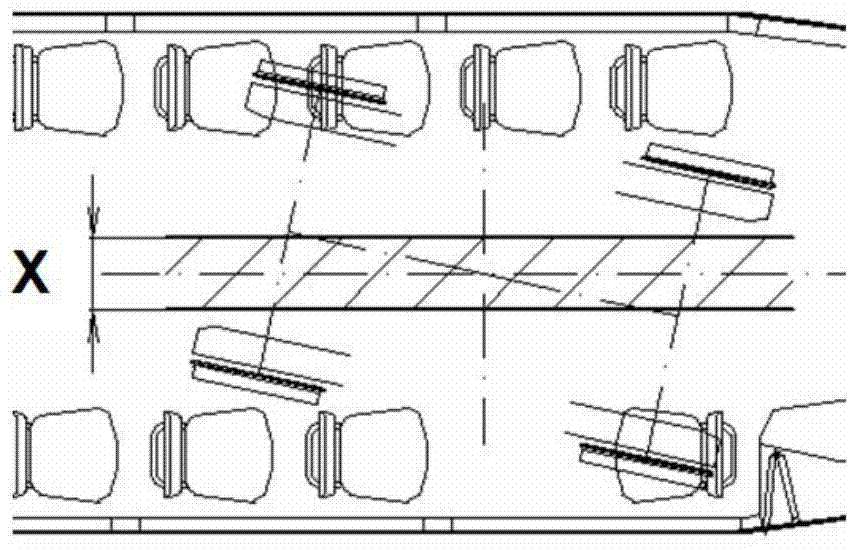

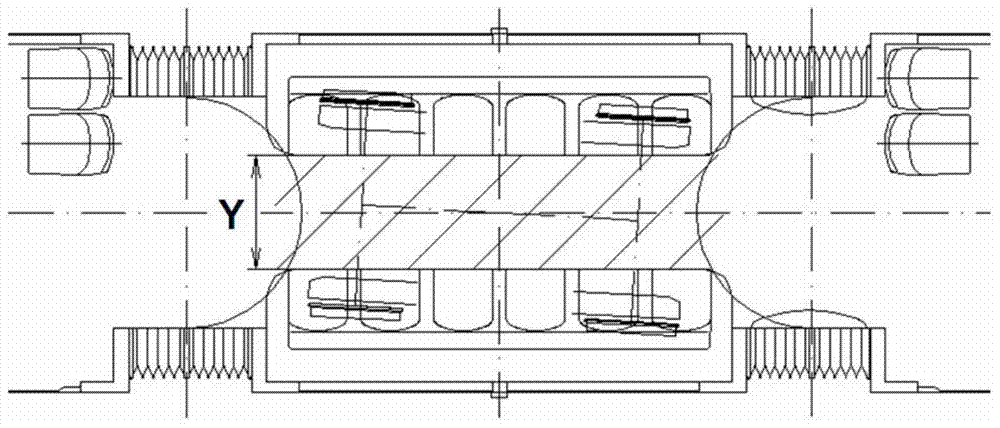

[0022] The position of the bogie is shown in the Figure 8 and Figure 9 middle. The bogies 1 and 2 are arranged in such a position that the elements of the primary and secondary elastic means 5 are located in the spaces between the pairs of separately mounted wheels of the bogies and that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com