Automatic system for attaching label

An automatic system and labeling technology, applied in the direction of labels, labeling machines, winding strips, etc., can solve the problems of feeding failure, difficulty in determining the exact position of the label queue, and inability to obtain pasting position information, etc., to achieve precise position control, The effect of high-speed peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, examples of embodiments of the present invention will be described in detail with reference to the accompanying drawings.

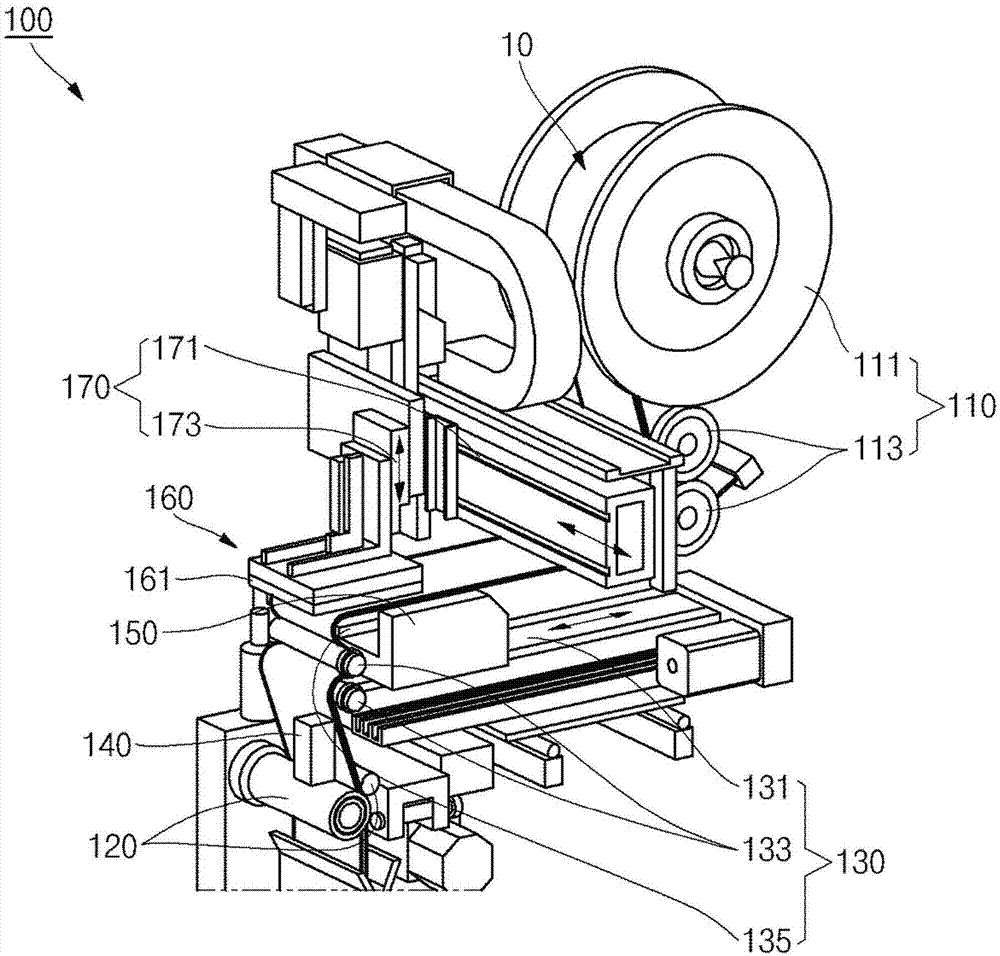

[0041] figure 1 is a perspective view showing the configuration of the automatic labeling system according to the embodiment of the present invention.

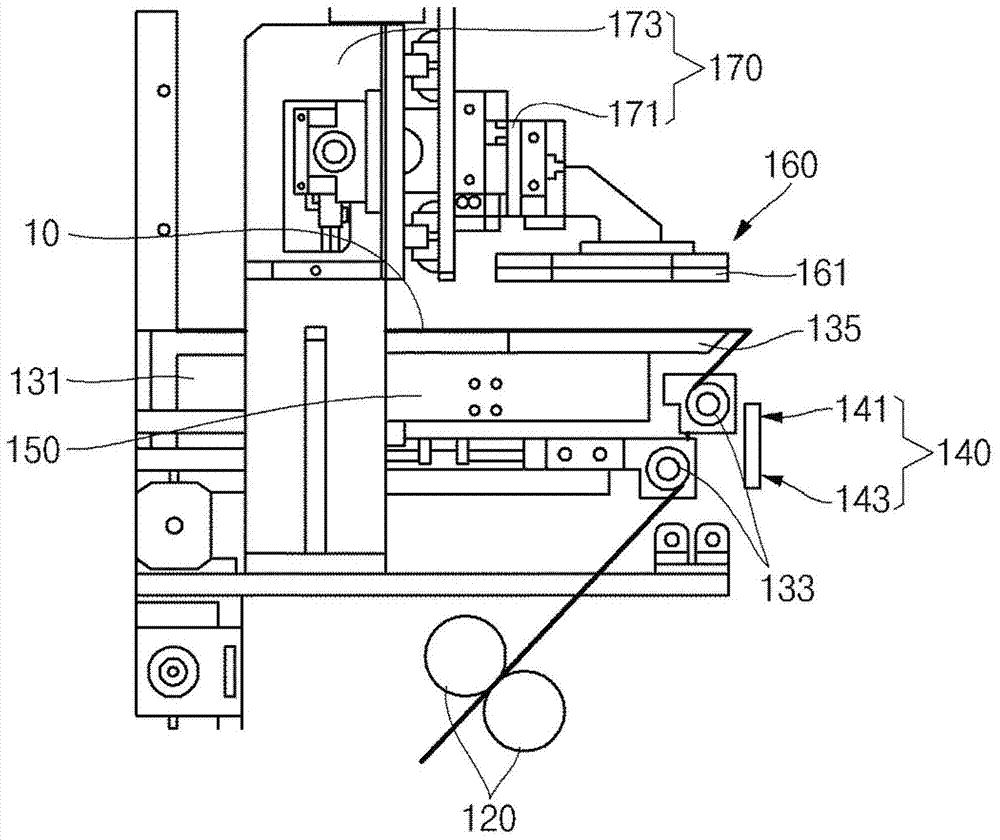

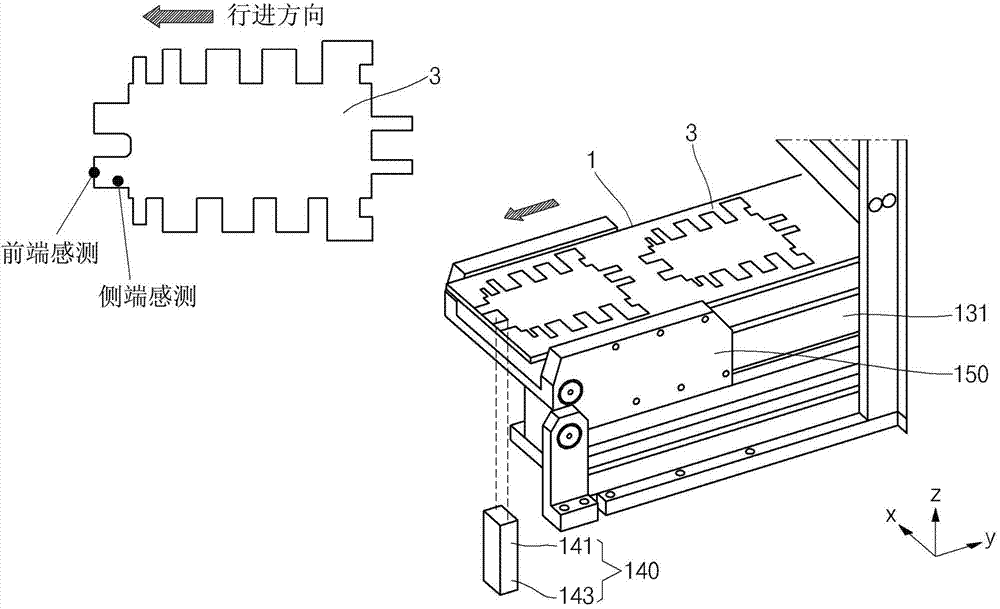

[0042] Figure 2 to Figure 4 shows the use of figure 1 The label sensing and peeling process of the automatic labeling system is shown in .

[0043] refer to Figure 1 to Figure 4 , the automatic labeling system 100 includes a label feeding unit 110 , a driving roller 120 , a front and rear driving unit 130 , a sensor unit 140 , a position adjustment unit 150 and a labeling unit 160 . The automatic labeling system 100 may also include a label delivery unit 170 .

[0044] The label feed unit 110 may include: a feed roller 111 on which the tape-shaped release sheet 10 is wound; a plurality of guide rollers 113 that guide the release sheet 10 so that it is drawn out along the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com