Connecting rod type workpiece machining device

A processing device and connecting rod technology, applied in the field of workpiece processing, can solve the problems of high equipment cost and unstable transmission, and achieve the effects of low cost, avoiding workpiece wear and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

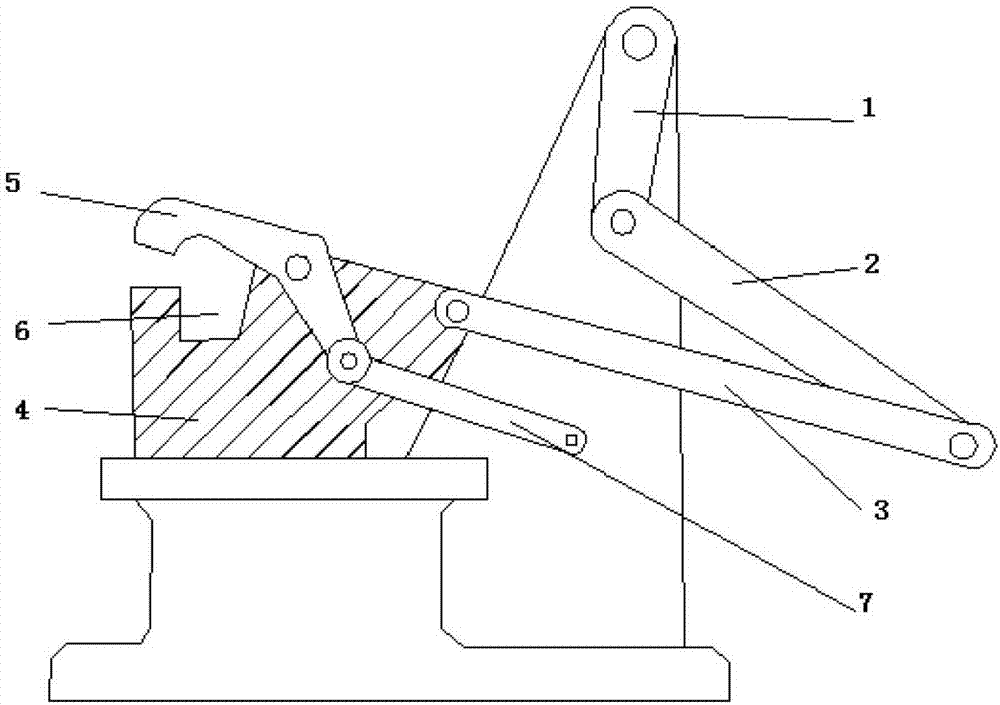

[0012] The reference signs in the description of the drawings are: crank 1, rotating swing rod 2, push connecting rod 3, processing boss 4, curved clamp body 5, clamping part 6, linkage arm 7.

[0013] Such as figure 1 As shown, the technical solution provides a link-type workpiece processing device, including a frame, a control device and a clamping device. The control device includes a crank 1, a rotating swing rod 2 and a push connecting rod 3, and the ratio of the length of the rotating swing rod 2 to the length of the crank 1 is 2:1. The crank 1 is rotatably connected to the frame and driven to rotate by the motor. The lower end of the crank 1 is hinged on the upper end of the rotating fork 2 , and the lower end of the rotating fork 2 is hinged on the left end of the push connecting rod 3 .

[0014] The clamping device includes a processing boss 4 and a curved clamp body 5, the right end of the processing table is hinged on the free end of the push connecting rod 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com