Process and device for producing liquefied natural gas by rectifying methane-rich gas to dehydrogenate nitrogen

A liquefied natural gas and methane-enriched technology, which is applied in liquefaction, refrigeration and liquefaction, gas fuel, etc., can solve the problems of methane component loss and inaccurate control of the amount, and achieve reduced equipment investment and maintenance costs, low impurity component content, The effect of high methane yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

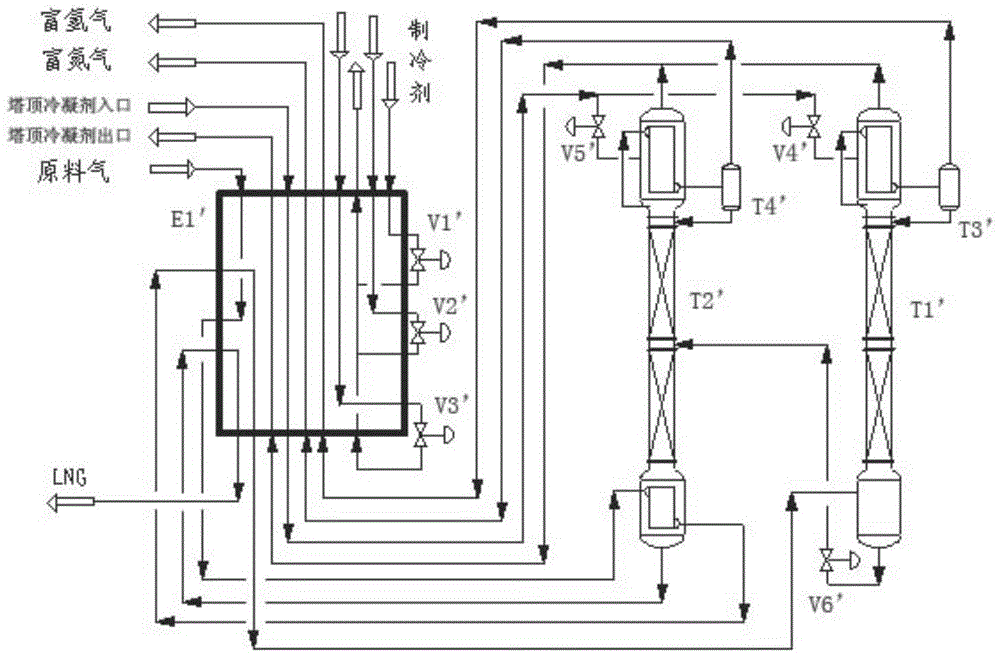

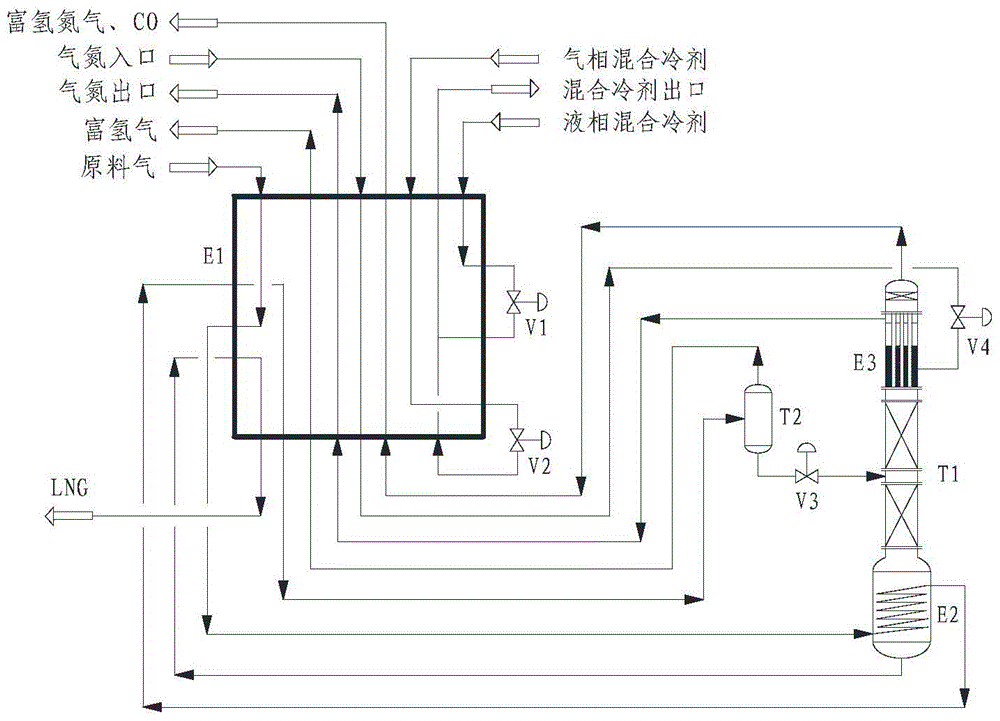

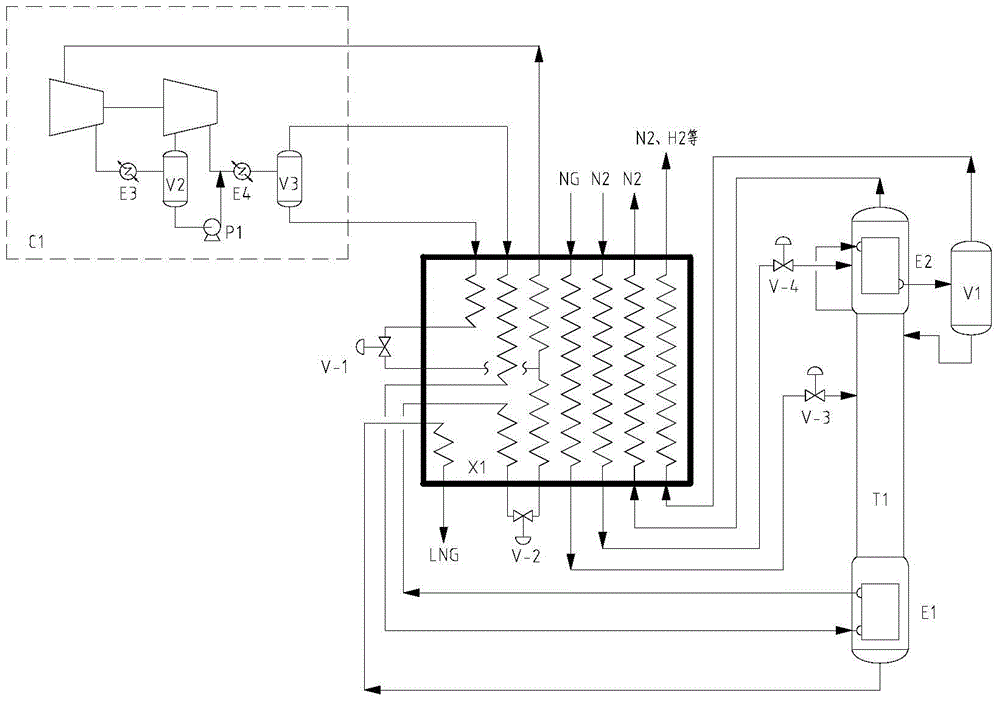

[0034] The process of the present invention includes two parts: low-temperature liquefaction and rectification separation; low-temperature liquefaction includes that methane-rich gas containing hydrogen and nitrogen first enters the cold box, and the methane component is liquefied in the cold box by the cooling capacity provided by the mixed refrigerant; rectification separation Including: the liquefied methane-rich gas containing hydrogen and nitrogen directly enters the single-column rectification tower for rectification to remove hydrogen, nitrogen and a small amount of carbon monoxide; the top of the rectification tower obtains a mixture of hydrogen, nitrogen and a small amount of carbon monoxide, the hydrogen, The mixed gas of nitrogen and carbon monoxide passes through the cold box to recover the cooling capacity and then exits the cold box system; the liquid phase at the bottom of the rectification tower is returned to the cold box for supercooling and then exits the syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com