Sewing Machines and Sewing Systems

A sewing machine and feeding mechanism technology, applied in the fields of sewing machines and sewing systems, can solve problems such as fixture fixing and connecting piece damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

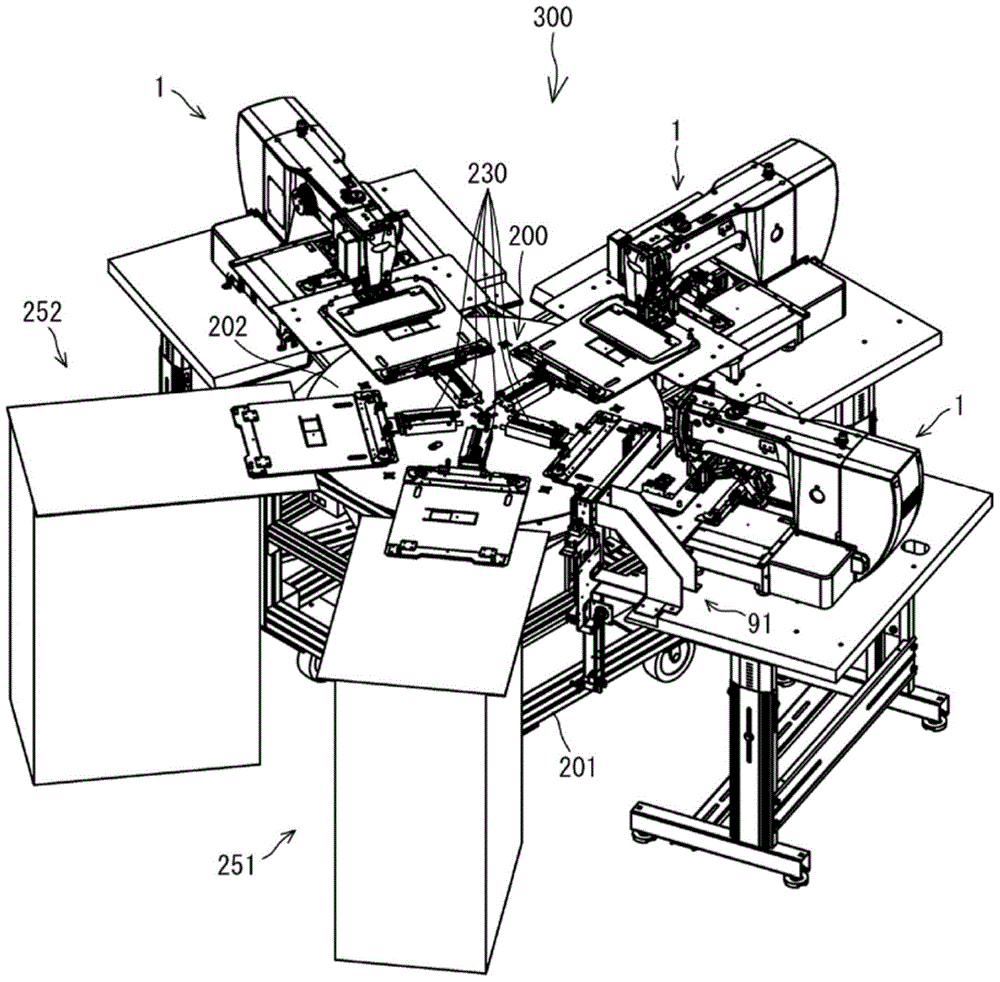

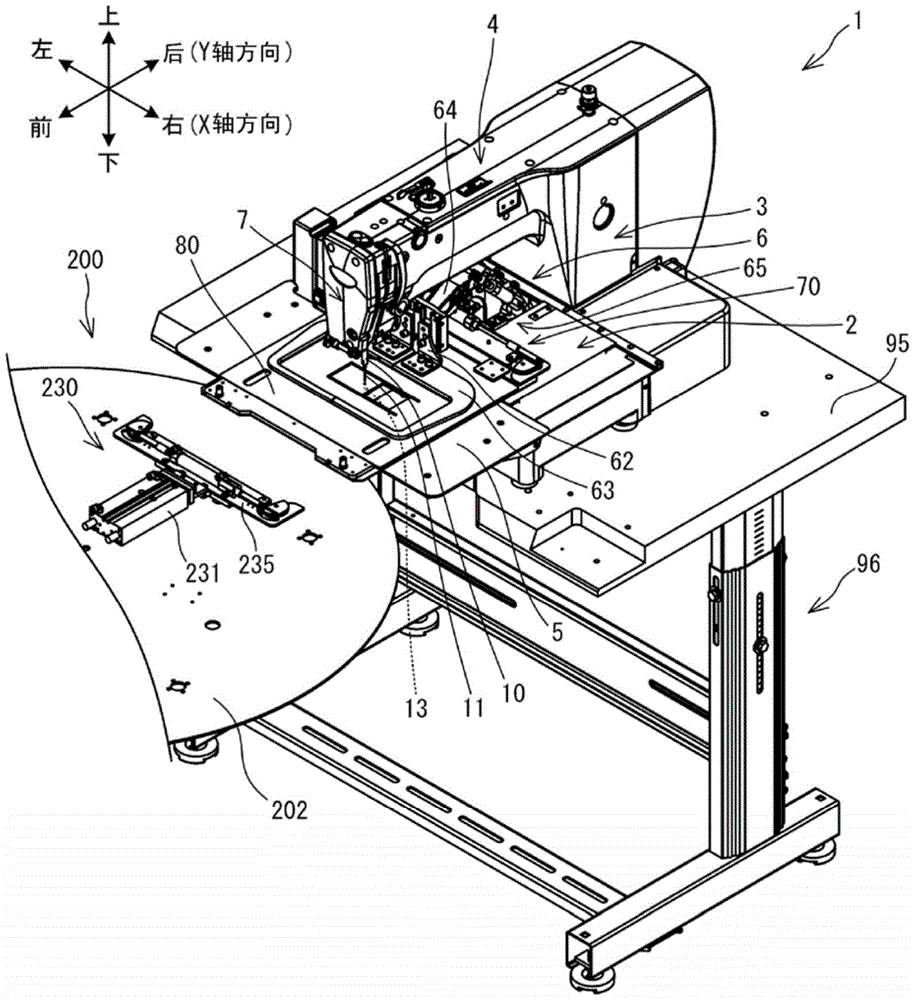

[0020] One embodiment of the present invention will be described with reference to the drawings. A schematic configuration of the sewing system 300 including the sewing machine 1 will be described. figure 2 The lower left, upper right, upper left, and lower right are the front, rear, left, and right of the sewing machine 1, respectively. like figure 1 As shown, the sewing system 300 includes the holding board supply device 200 , a plurality of (three in this embodiment) sewing machines 1 , and two consoles 251 and 252 . The sewing machine 1 and the consoles 251 and 252 are arranged radially in plan view with the holding plate supply device 200 at the center. One sewing machine 1 among the plurality of sewing machines 1 is provided with a part supply device 91 on its side. The through hole 826 of the accessory supply device 91 to the holding plate 80 (refer to Figure 5 ) to supply accessories for sewing objects. The holding plate 80 holds a sewing object (for example, cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com