PVC material suitable for sewing and its making method

A manufacturing method and sewing technology, applied to chemical instruments and methods, steering control installed on vehicles, synthetic resin layered products, etc., can solve problems such as weak joints and cracks, facilitate production, and avoid cracks or cracks The effect of opening and combining firmly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

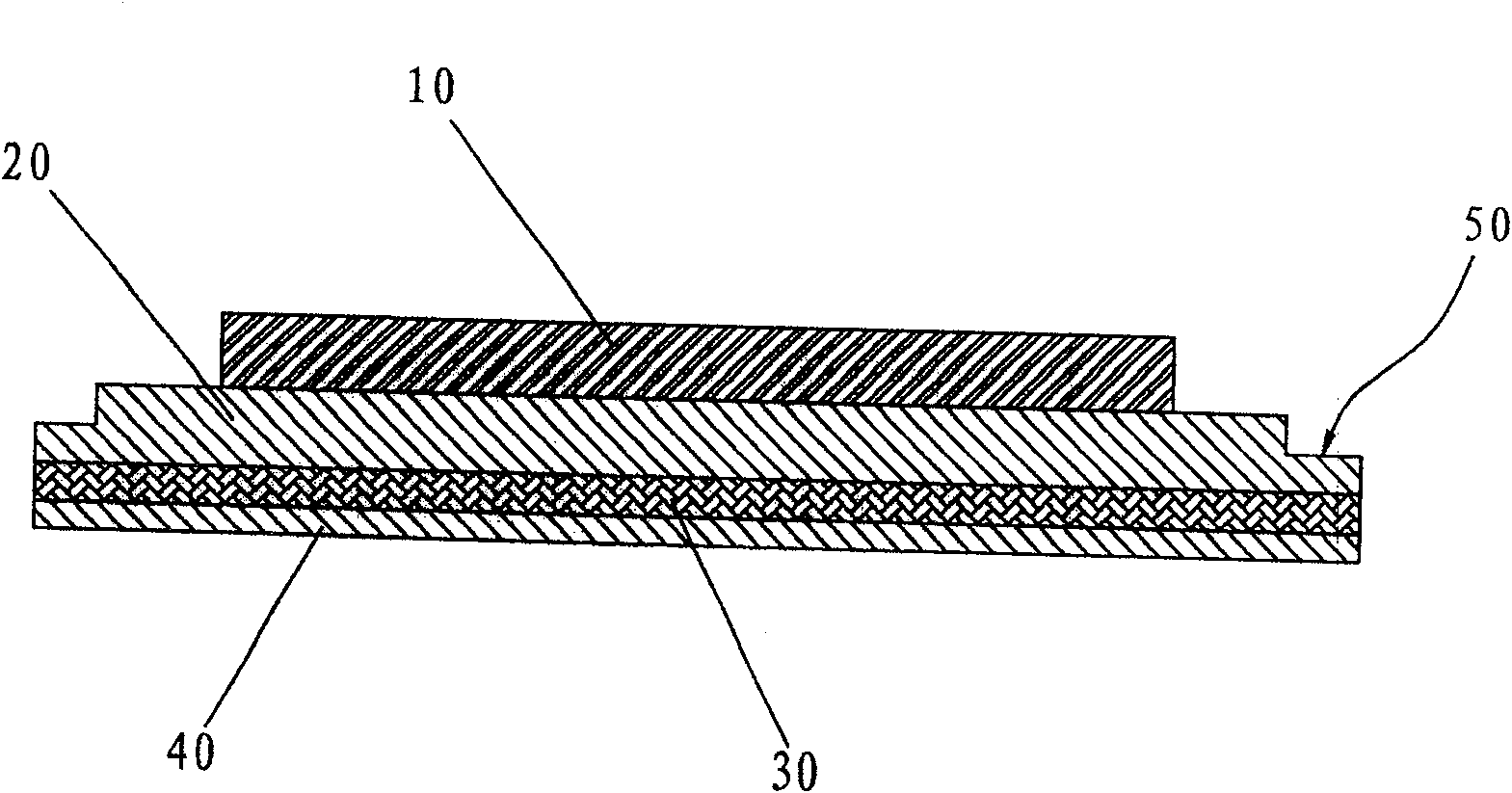

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0012] A method for making PVC materials suitable for sewing. First, a pattern layer or a modeling layer is formed on the bottom of the mold, and then filled with paste PVC. When the PVC is in a semi-dry state, a cloth layer is laid on it, and then the cloth is filled A thin layer of liquid PVC is injected on the layer, then heated and solidified, and then demoulded to obtain a PVC material. The peripheral edge of the PVC material used for sewing is thinner than other positions; the cloth layer is non-woven fabric.

[0013] Such as figure 1 As shown, a kind of PVC material suitable for sewing made by the above method includes a pattern layer or a modeling layer 10 (such as the pattern layer can be formed by PVC fine powder in a small amount, and the surface of the modeling layer has various shapes. PVC block), the PVC main layer 20 formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com