Floor tile jointing device

A technology for beautifying joints and floor tiles, which is applied in the direction of construction and building construction, can solve the problems of wasting beautifying agents, secondary damage to the edge of floor tiles, and wasting a long time, so as to prevent smearing deviation, regular beautifying joints and beautiful ground Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

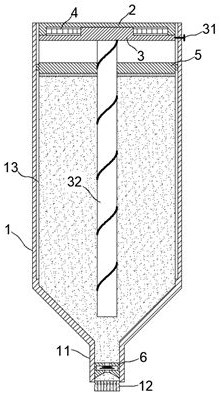

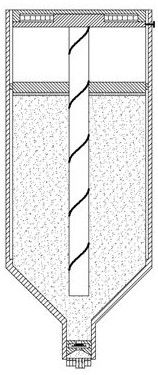

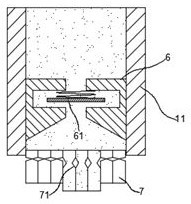

[0020] exist figure 1 , figure 2 , image 3 In the shown embodiment, the local brick beautifying device includes a bottle body 1, a spray pipe 11 and a nozzle 12; the beautifying agent is filled in the bottle body 1; The extrusion part includes a drive plate 2 and a transmission plate 3 arranged at the bottom of the bottle body 1, and the drive plate 2 and the drive plate 3 are arranged in parallel; a ratchet structure is provided on the outer edge of the drive plate 2 with rotational symmetry , a ratchet structure matching the ratchet structure is provided on the inner wall of the bottle body 1 facing the outer edge of the drive disc 2, and the ratchet structure and the ratchet structure are made of elastic materials; the drive disc 3 and the bottle body 1 are slidably connected by a slip ring and a ring groove structure, and the drive plate 3 can rotate freely relative to the bottle body 1; a limit button 31 for limiting the rotation of the drive plate 3 is also provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com