T section steel

A T-shaped steel and wing plate technology, applied in the direction of sheet/board, building elements, etc., can solve the problems affecting the stability and safety of buildings, stability effects, etc., and achieve simple structure, low processing cost, and improved connection strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

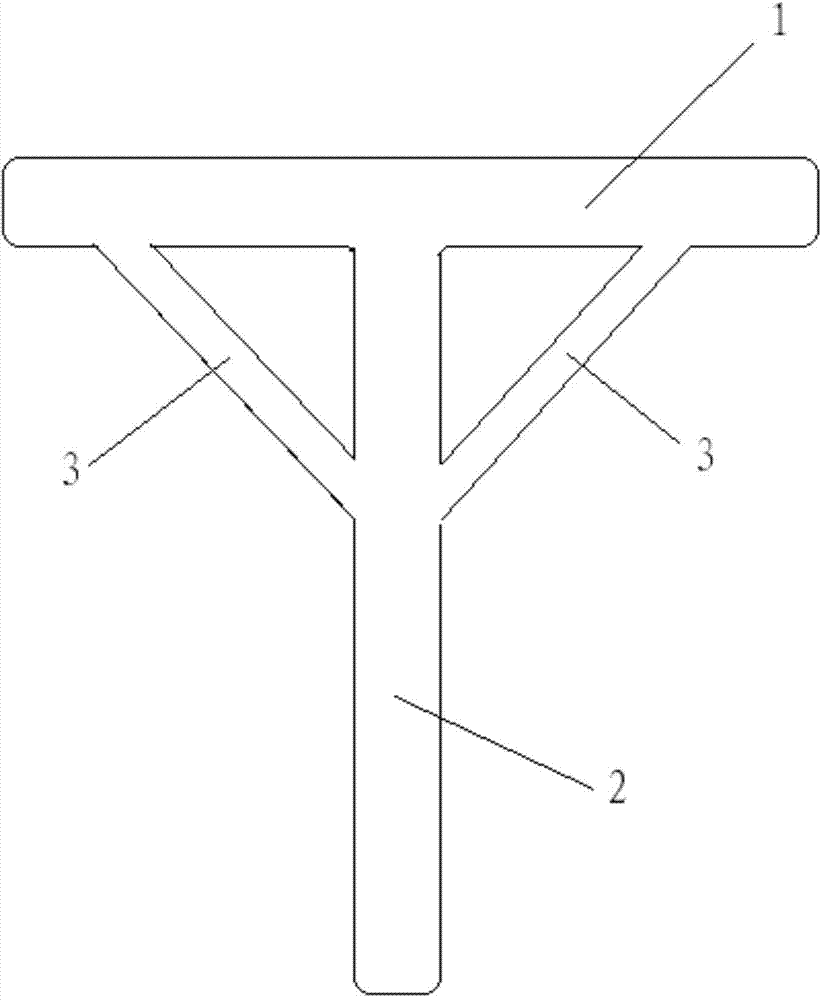

[0010] Such as figure 1 As shown, the present invention provides a T-shaped steel, including a wing plate 1 and a web 2, a reinforcing mechanism 3 is provided between the wing plate 1 and the web 2, and the reinforcing mechanism 3 is obliquely connected The wing plate 1 and the web plate 2 .

[0011] Further, the reinforcing mechanism 3 is an intermittent block.

[0012] The advantages and positive effects of the present invention are: due to the adoption of the above technical solution, the reinforcing mechanism 3 can well improve the connection strength between the wing plate 1 and the web plate 2, and it is not easy to deform when subjected to relatively large pressure and torque The interrupted block will not increase the manufacturing cost of a lot of T-shaped steel, and whether it is welding or other forms, it will not affect the shape of the flange and web itself; it has the advantages of simple structure, low processing cost, and high production efficiency.

[0013] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com