Quality factor-based device and method for detecting loudspeaker module sealing

A technology of quality factor and speaker module, which is applied in the field of sound and electricity, can solve the problems of sound quality damage and misjudgment of speaker modules, and achieve the effects of reducing detection costs, reducing secondary investment, and preventing damage and misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In the following description, for illustrative purposes, many specific details are set forth in order to provide a comprehensive understanding of one or more embodiments. However, it is obvious that these embodiments can also be implemented without these specific details.

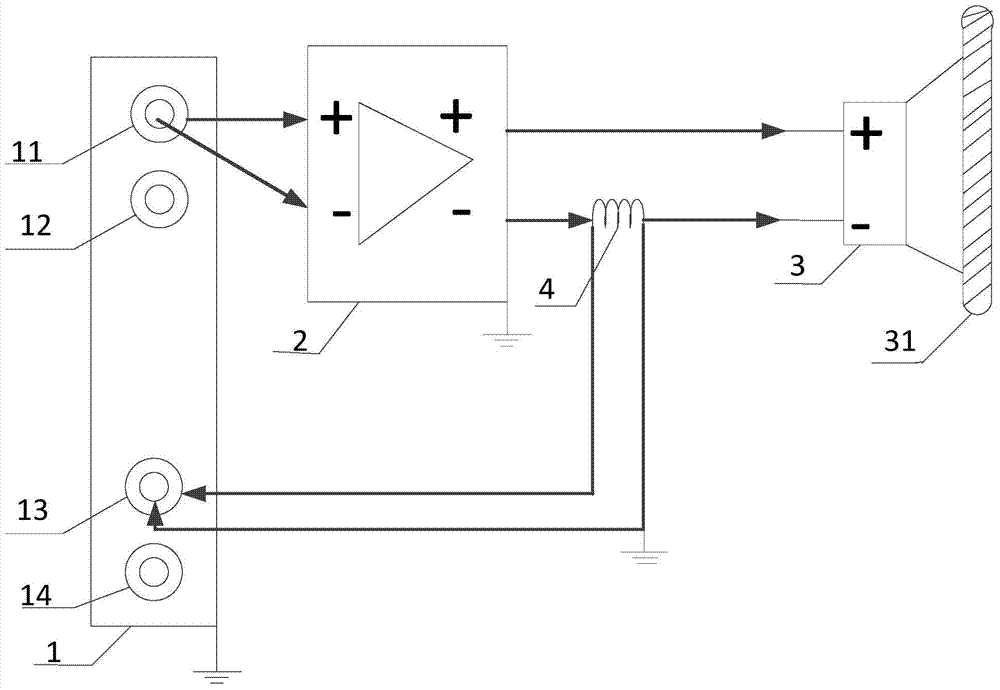

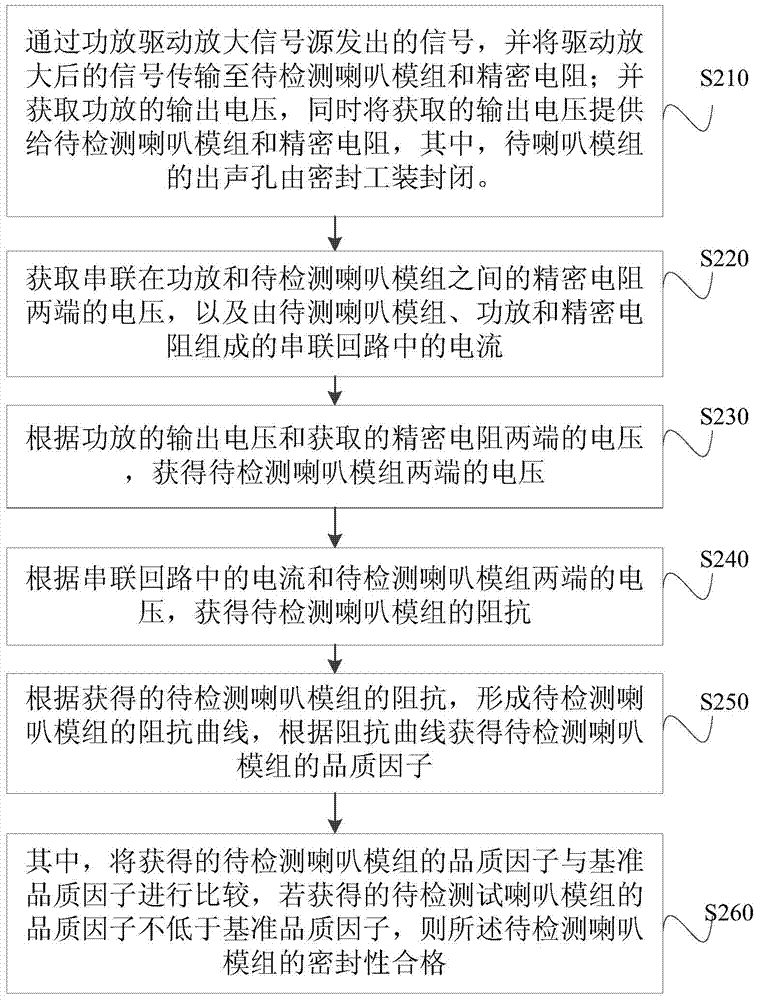

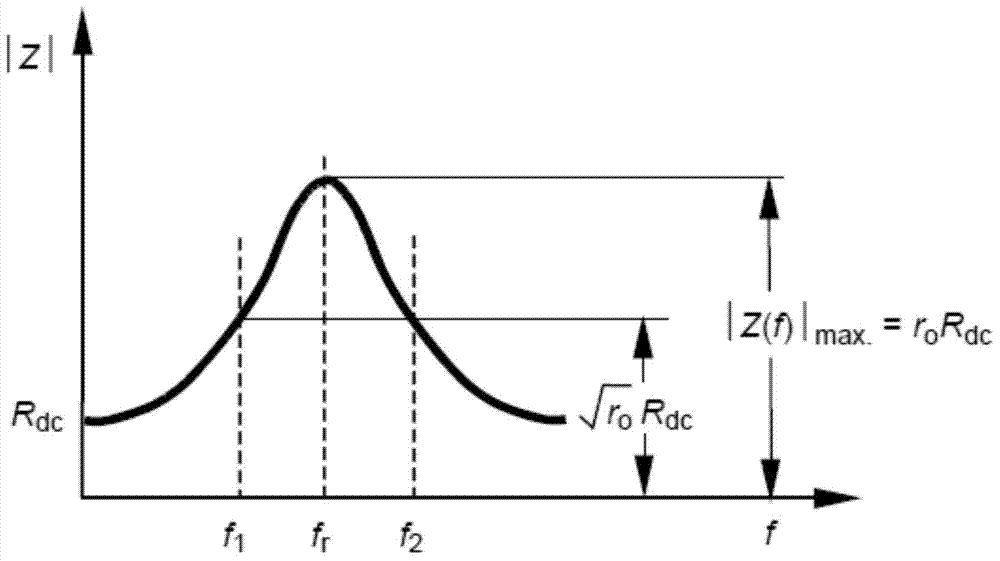

[0045] Aiming at the problems of damaging the sound quality of the speaker module and prone to misjudgment when detecting the sealing of the speaker module through the water immersion method and the lip sound test method proposed above, the present invention uses the airflow generated by the speaker module according to the magnitude of the airflow resistance. Calculate the quality factor of the speaker module, and detect whether the speaker module is leaking according to its quality factor, which can effectively prevent the sound quality of the speaker module from being damaged and subjective misjudgment. At the same time, the equipment used in the present invention is the basic instrument in the perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com