Cable tightener

A technology of tightener and cable, which is applied in the field of medical equipment, can solve the problems of inability to tighten the cable alone, slow tightening of the cable, and increased operation time, so as to achieve safe and reliable binding operation, high work efficiency, and reduced use cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] The technical scheme of the present invention will be further described in detail below in conjunction with the drawings and preferred embodiments.

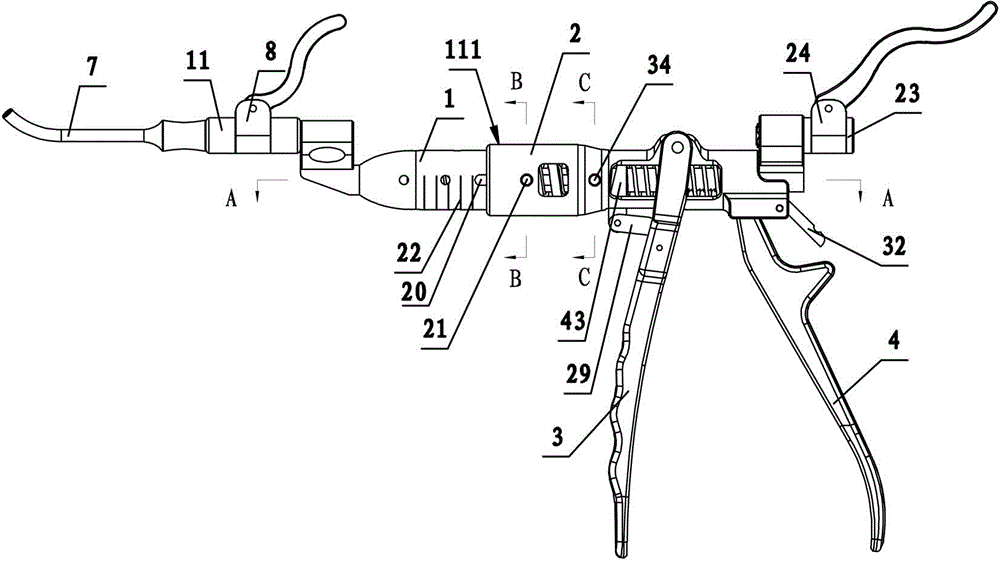

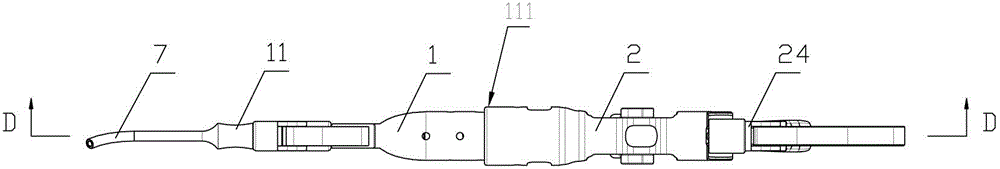

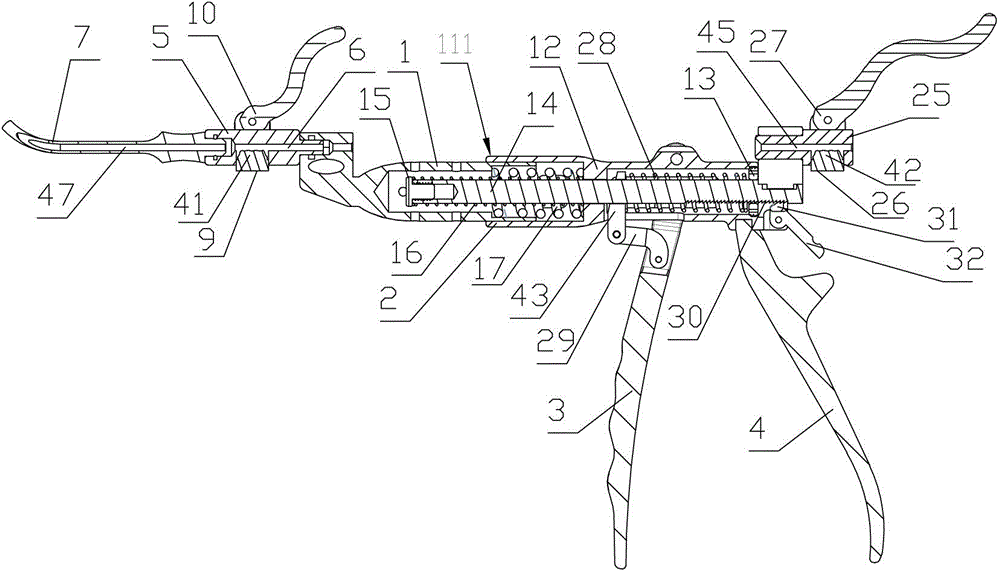

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the cable tightening device includes a cylinder 111. The cylinder 111 is equipped with a grip 4 and a trigger 3 that can be moved back and forth. The front end of the cylinder 111 is provided with a front cable assembly 11, which 11 includes a front connecting cylinder 5, the front connecting cylinder 5 is axially provided with a front cable passage 6 through which cables can pass, and the front connecting cylinder 5 is provided with a front cable locking mechanism 8 through which the front cable locking mechanism 8 The cable can be locked in the front cable passage 6. In this embodiment, the front cable locking mechanism 8 includes a first notch provided at the bottom of the front connecting cylinder 5 and a bottom-to-up sleeve in the front. Connected to th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap