Filler support device

A support device and support ring technology, which is applied in the field of packing support devices, can solve the problems of axial deformation of packing discs, non-compliance with the structural characteristics of packing discs, and reduce the rectification efficiency of rectification towers, etc., so as to achieve the effect of reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

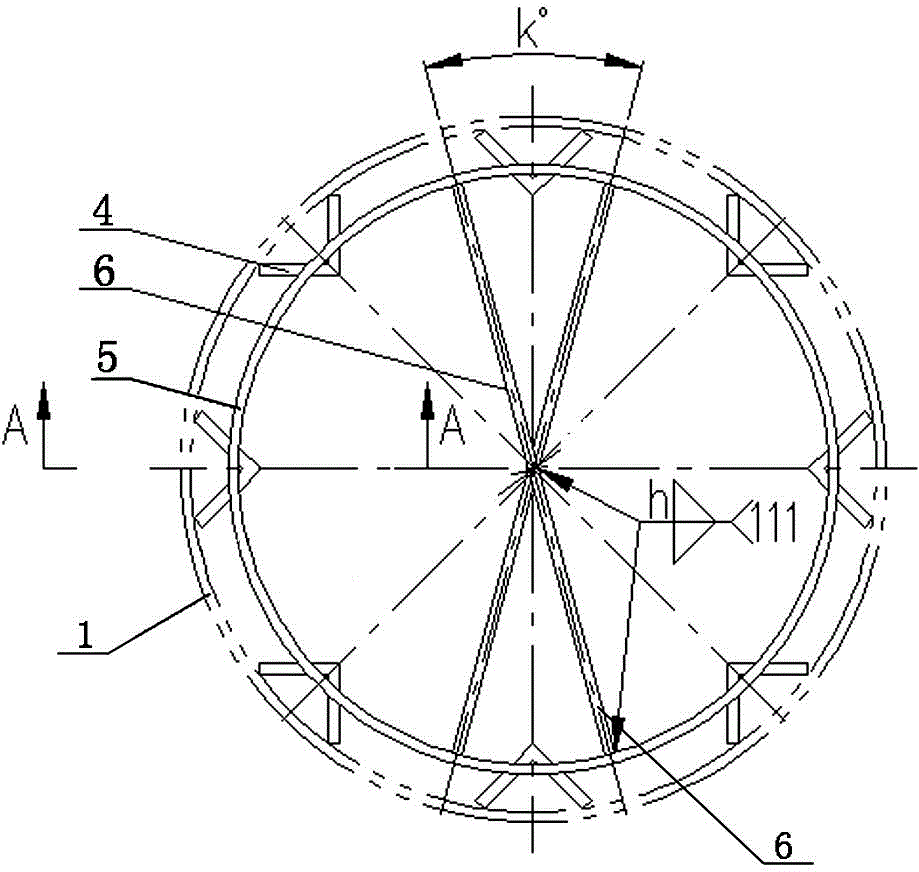

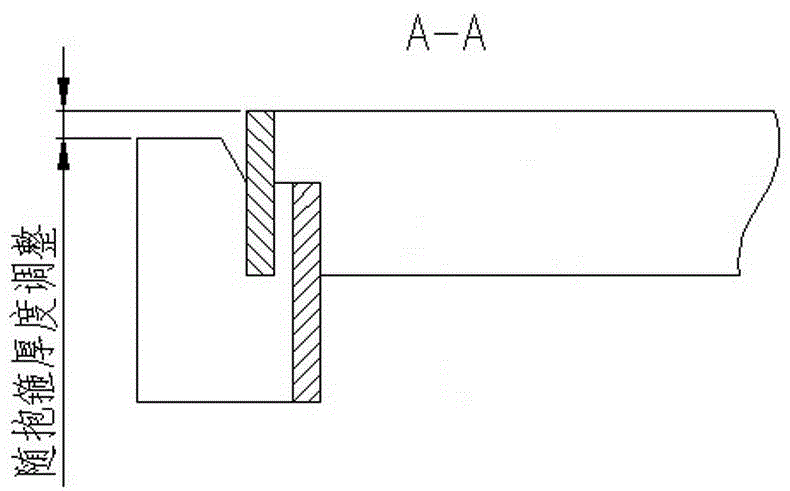

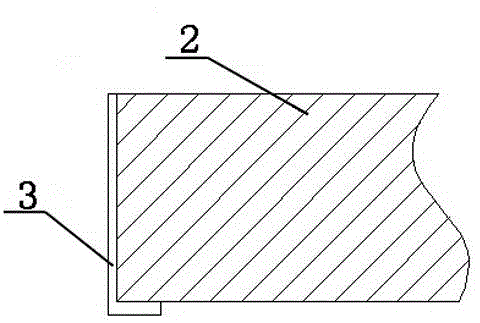

[0015] In the present invention, the angular aluminum frame 4 uniformly distributed in the circumferential direction is mainly used to support the hoop of the packing plate, and bear the weight of the entire packing plate; the annular plate frame is mainly used to support the packing, and the circumferential support can ensure that each corrugation of the packing The plates can be effectively supported; the radially arranged reinforcing plates are best used for large-size packing pans, and it is better to use when the packing corrugated plates themselves are not rigid enough. The combination of the annular plate frame and the angular aluminum frame in the present invention is a placed structure, which ensures that the rectification tower will not generate stress caused by the support ring during operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com