A kind of preparation method of material for adsorption and purification of PM2.5

A technology of organic fiber and mass ratio, applied in the field of materials, can solve the problems of contradiction between filtration performance and air permeability, small pore structure, poor air permeability, etc., and achieve the effect of easy industrial production, low production cost, and strong adsorption and removal function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

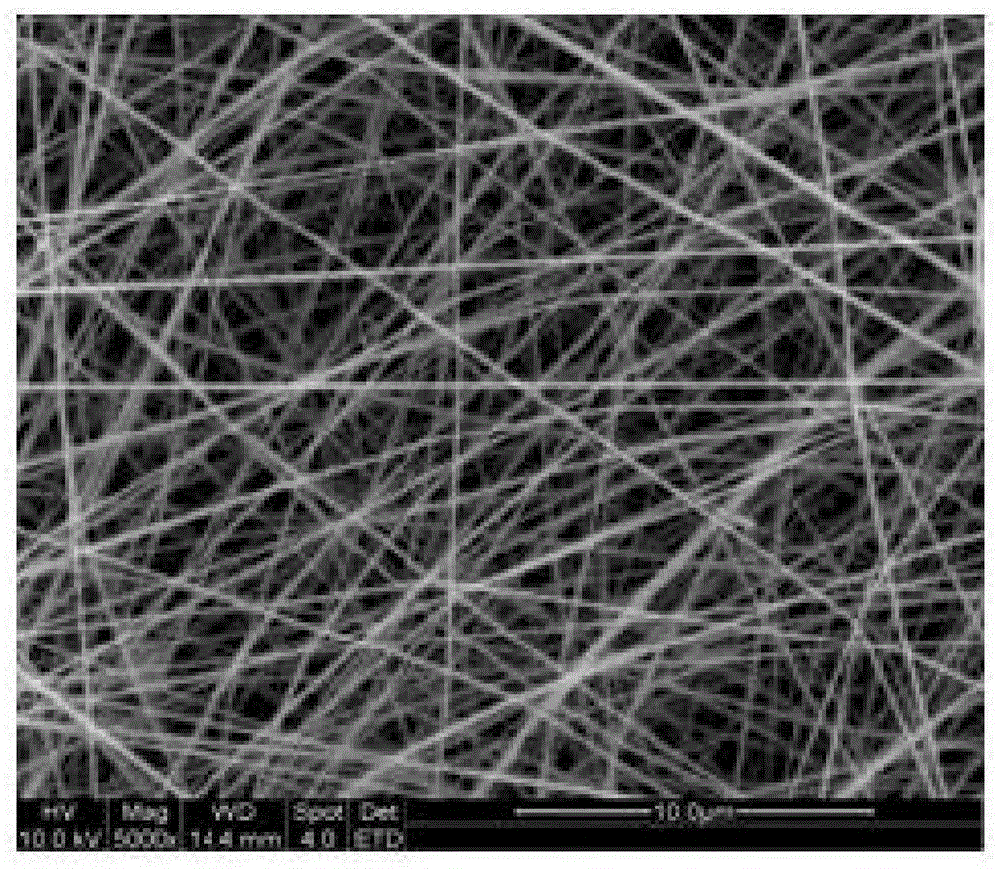

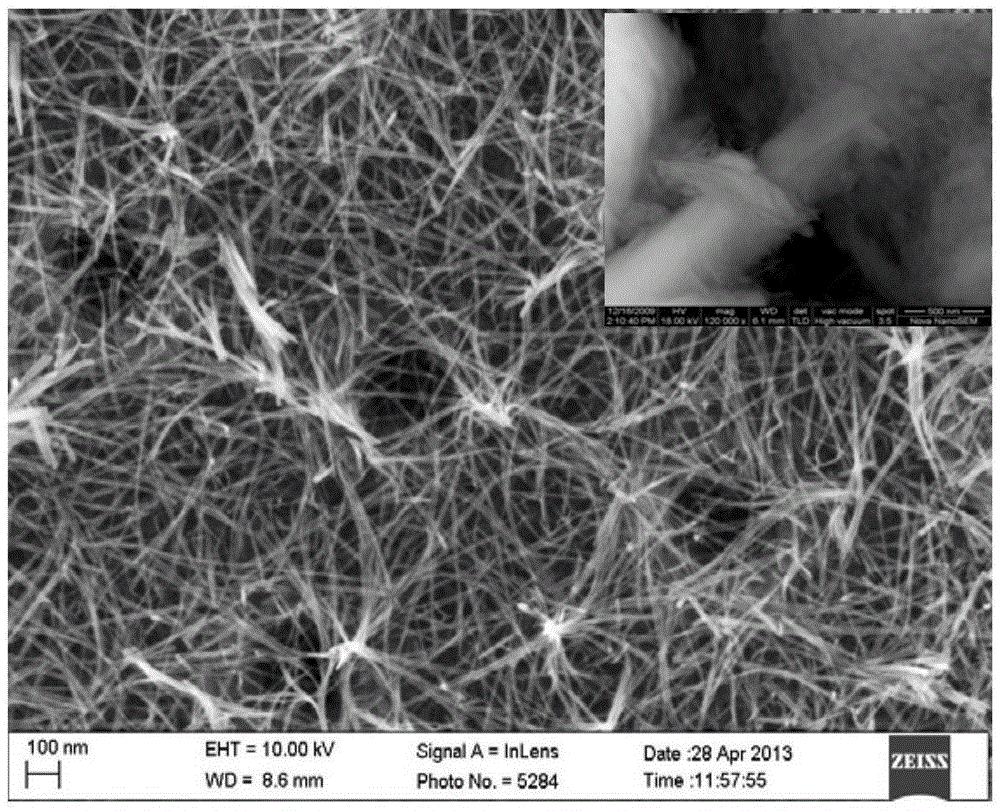

Method used

Image

Examples

Embodiment 1

[0034] 1. Take 20g of pulp fiber and add it to 4L of water, and add 12g of sodium hexametaphosphate to form a uniformly dispersed fiber pulp suspension after stirring, add 6g of wood fiber (30-40mm in length, Heilongjiang coniferous forest wood fiber) , 0.75g polyester fiber, and fully stir evenly.

[0035] 2. Take 500ml of the above-mentioned suspension (after fully stirring evenly, the fiber concentration will be constant, and the fiber amount will be determined when a certain amount of suspension is taken, that is, 3.34g), and use a mesh sieve to take the organic matter in the mixed suspension. Fiber, add 6.7g of opal mineral powder and mix well.

[0036] 3. After stirring evenly, take out the fibers attached to the opal powder and spread them flat, and dehydrate and dry them in a 120°C drying oven. The thickness of the product after drying is 0.1mm. Take out the sample (see photo of the sample figure 2 ), the adhesive film (polyester adhesive film, pore size 3um) is att...

Embodiment 2

[0038] 1. Take 20g of pulp fiber and add it to 6L of water, and add 24g of sodium hexametaphosphate to form a uniformly dispersed fiber slurry suspension after stirring, add 10g of wood fiber, 0.9g of polypropylene fiber (length is 5 ~ 20mm), and Stir well to combine.

[0039] 2. Take 1000ml of the above suspension, use a mesh sieve to take the organic fiber in the mixed suspension (the dry weight of the fiber is 5.15g at this time), add 11g of opal powder, and mix well.

[0040] 3. After stirring evenly, remove and smooth the fibers attached to the opal powder, dehydrate and dry in a 100°C drying oven, and the thickness of the product after drying is 0.2mm. The sample was taken out, and an adhesive film (polyester adhesive film, pore size 3 μm) was attached to both sides of the sample.

Embodiment 3

[0042] 1. Take 15g of pulp fiber and add it to 2L of water, and add 7g of sodium hexametaphosphate to form a uniformly dispersed fiber slurry suspension after stirring, add 0.45g of polypropylene fiber (5-20mm in length), 0.3g of polyester fiber ( The length is 15 ~ 50mm), and fully stir evenly.

[0043] 2. Take 800ml of the above suspension, at this time the dry weight of the fiber is 6.3g, use a mesh sieve to sieve the organic fiber in the mixed suspension, add 12.5g of opal powder, and mix well.

[0044] 3. After stirring evenly, remove and smooth the fibers attached to the opal powder, and dehydrate and dry them in a drying oven at 100°C. Take out the sample, and the thickness of the product after drying is 0.3mm. Adhesive films (polyester adhesive films, pore size 3 μm) were attached to both sides of the sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com