Technology for discharging desulfurized wastewater according to standards

A desulfurization wastewater and process technology, applied in the direction of gaseous effluent wastewater treatment, water pollutants, multi-stage water treatment, etc., can solve the problem that the content of SS, COD and heavy metals is easy to exceed the standard, and it is difficult to return water for direct application or subsequent treatment for reuse , Clarify the unstable operation of the system and other issues, to achieve the effect of low cost of medicine use, small footprint, and low implementation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

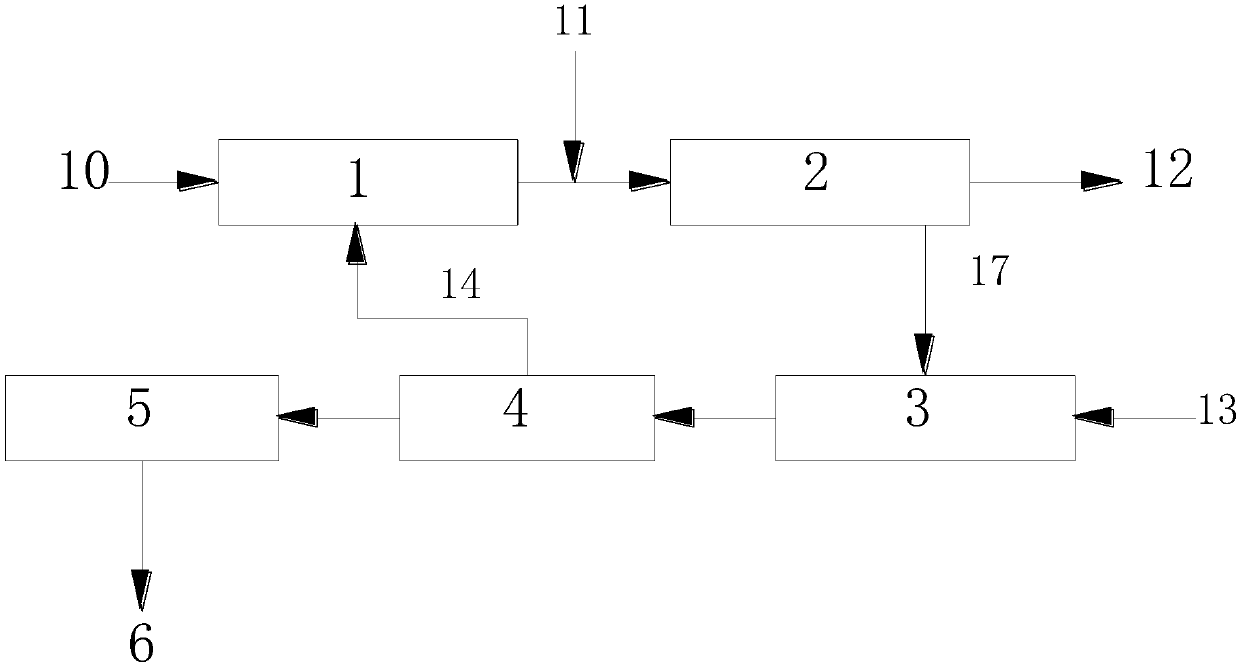

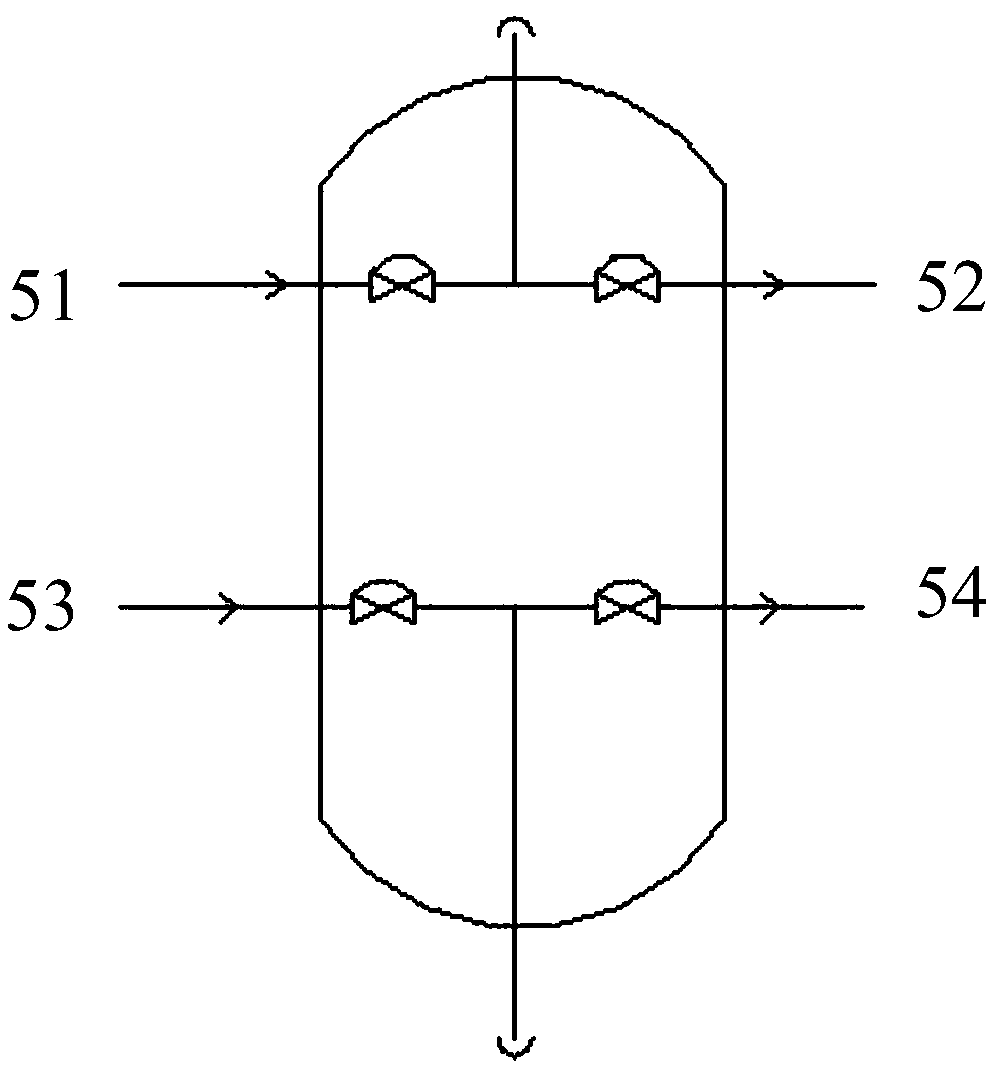

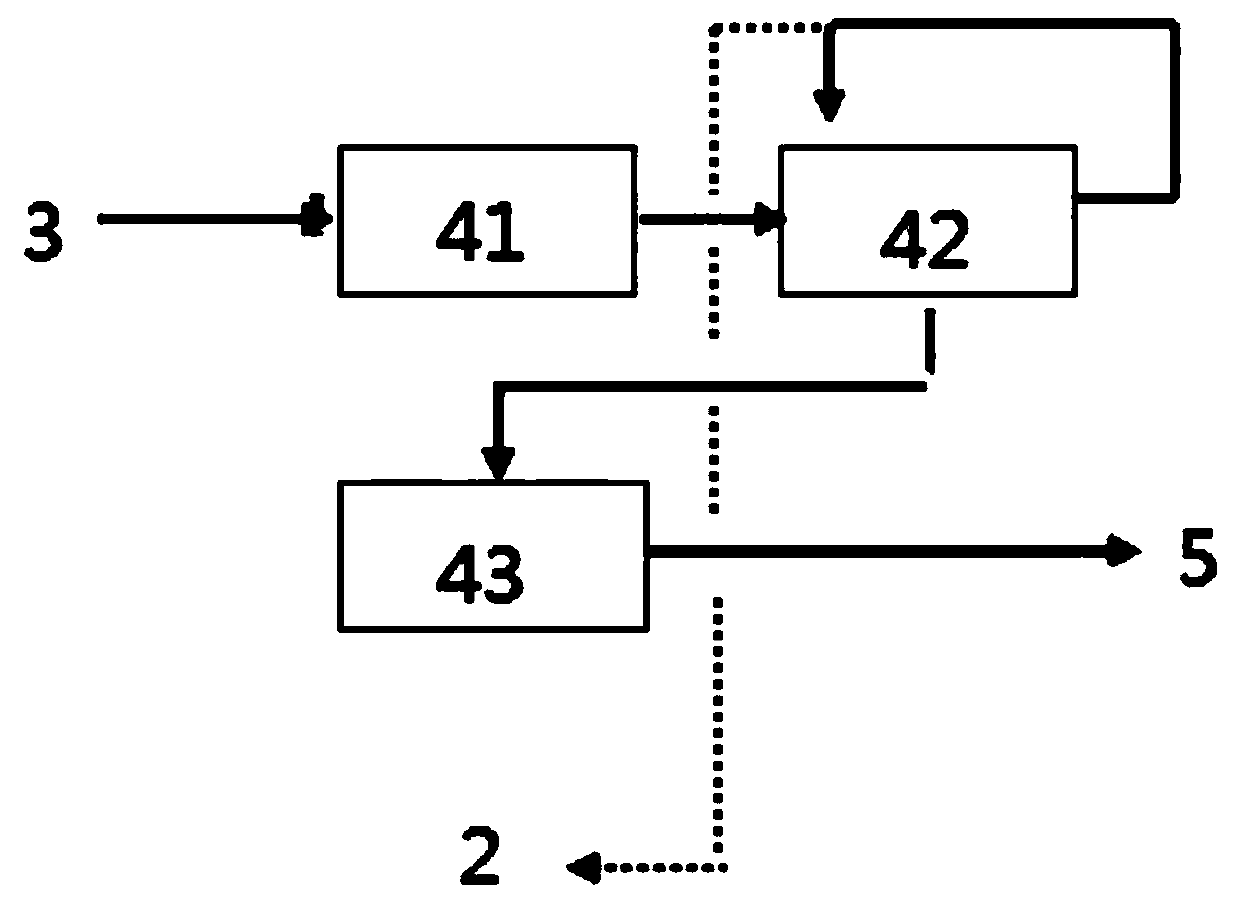

[0022] Please refer to Figure 1 to Figure 3 . Embodiment 1 of the present invention provides a desulfurization wastewater up-to-standard discharge process, and the desulfurization wastewater up-to-standard discharge process is hereinafter referred to as WDS process (Watersound High-efficiency

[0023] desulfurization wastewater discharge standard discharge process), including pretreatment steps, secondary filtration steps and discharge steps. The pretreatment step includes adding 200ppm of the composite reagent 11 to form a precipitate from the heavy metals, COD substances and suspended matter in the desulfurization wastewater 10, and filtering the precipitate once; the secondary filtration step includes adjusting the pH of the filtrate after the primary filtration to 6 ˜9, filtering out the sediment for the second time; and the discharging step includes discharging the filtrate after the second filtering. In this embodiment, the desulfurization waste water standard dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com