Torsional vibration damper

A technology of torsional vibration and shock absorber, applied in the direction of spring/shock absorber, vibration suppression adjustment, mechanical equipment, etc., can solve expensive problems and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

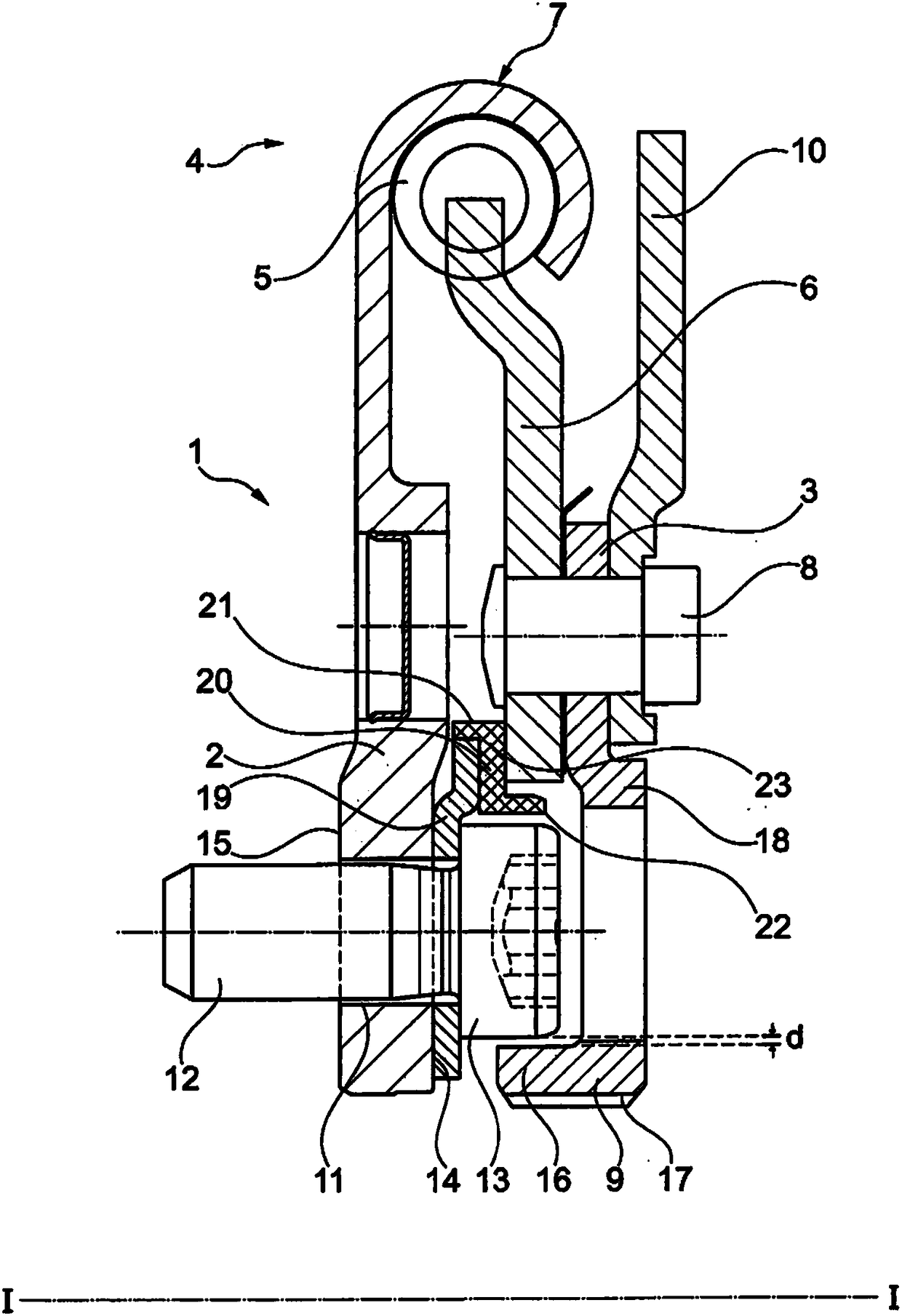

[0019] figure 1 The torsional vibration damper 1 is shown in a schematic partial section. In this case, the torsional vibration damper 1 is designed to be torsion about an axis I-I, which also constitutes a reference for the axial direction, the radial direction or the circumferential direction.

[0020] The torsional vibration damper 1 has an input element 2 and an output element 3 which are arranged torsionally relative to one another about an axis I-I. Typically, the input element 2 can be connected to an element in the drive train of the motor vehicle. The connection can be realized, for example, with the crankshaft of the internal combustion engine or also otherwise. Typically, the output element 3 can be connected to downstream elements in the drive train of the motor vehicle. The connection can be, for example, to a transmission input shaft. When using the torsional vibration damper 1 as a dual clutch damper, the torsional vibration damper 1 can be integrated into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com