Gas purification equipment

A gas purification equipment and gas technology, applied in the direction of using liquid separation agents, chemical instruments and methods, combined devices, etc., can solve the problems of reduced efficiency, consumption, large land occupation and water, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

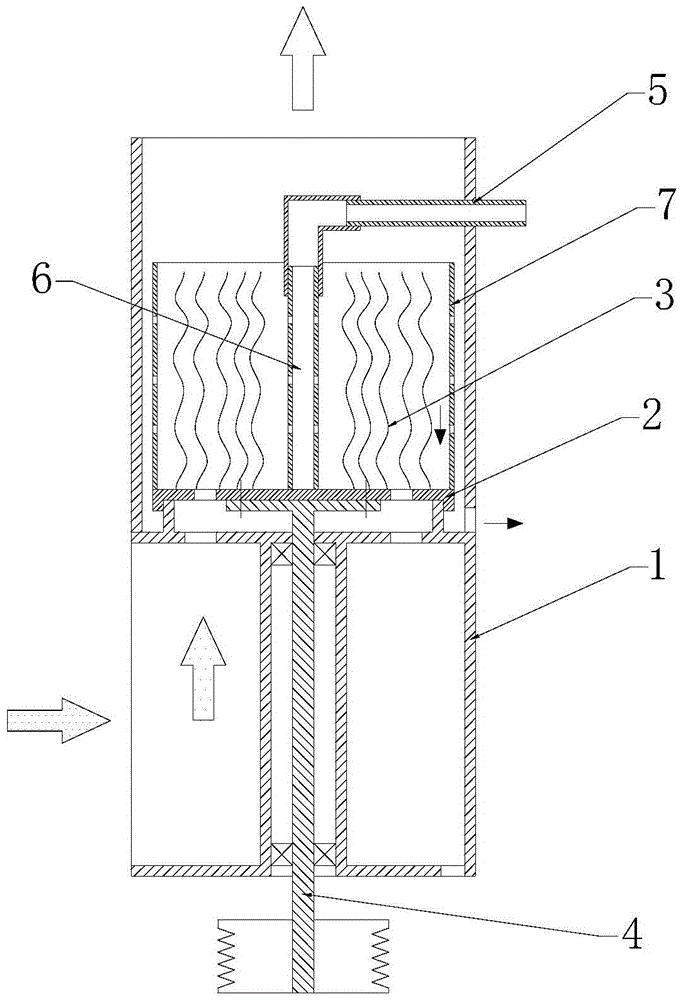

[0031] refer to figure 1 , figure 1 The hollow arrow indicates the gas flow direction, and the solid arrow indicates the flow direction of the liquid and particle mixture.

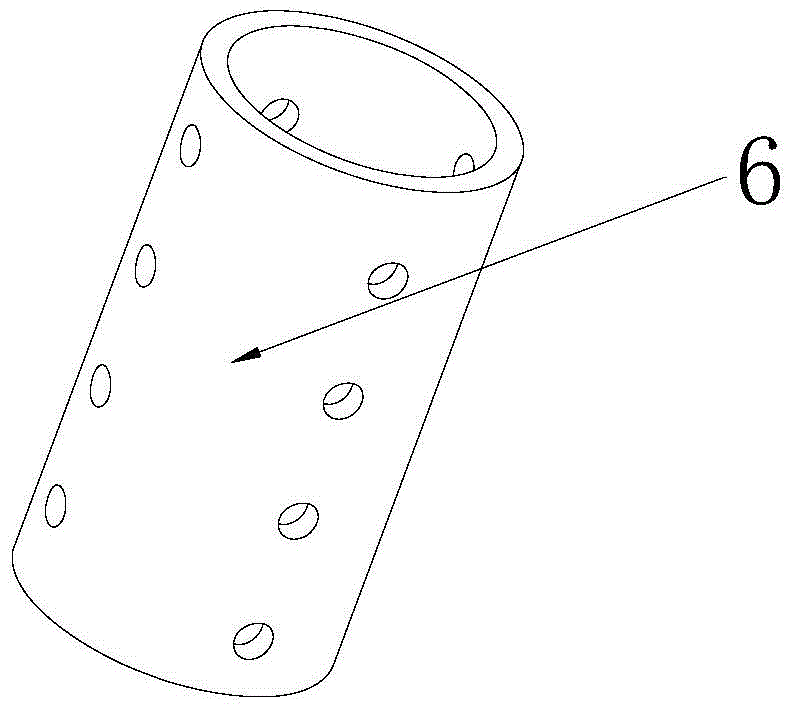

[0032] This embodiment provides a gas purification device, which includes a housing 1, a bottom plate 2, a first centrifugal washing water dispersion device 3, a rotating mechanism 4, a first water inlet pipe 5 and a first water spray device 6;

[0033] The housing 1 is cylindrical, and a gas circulation channel is formed inside it, preferably, the lower part of the side wall of the housing 1 is provided with an opening (gas inlet), and the top of the housing is provided with an opening (gas discharge port), the gas circulation passage communicates with the opening on the side wall of the housing and the opening on the top of the housing; the flow direction of the gas in the gas circulation passage is from bottom to top, and the gas flows through the The flow in the passage can force the gas flow through...

Embodiment 2

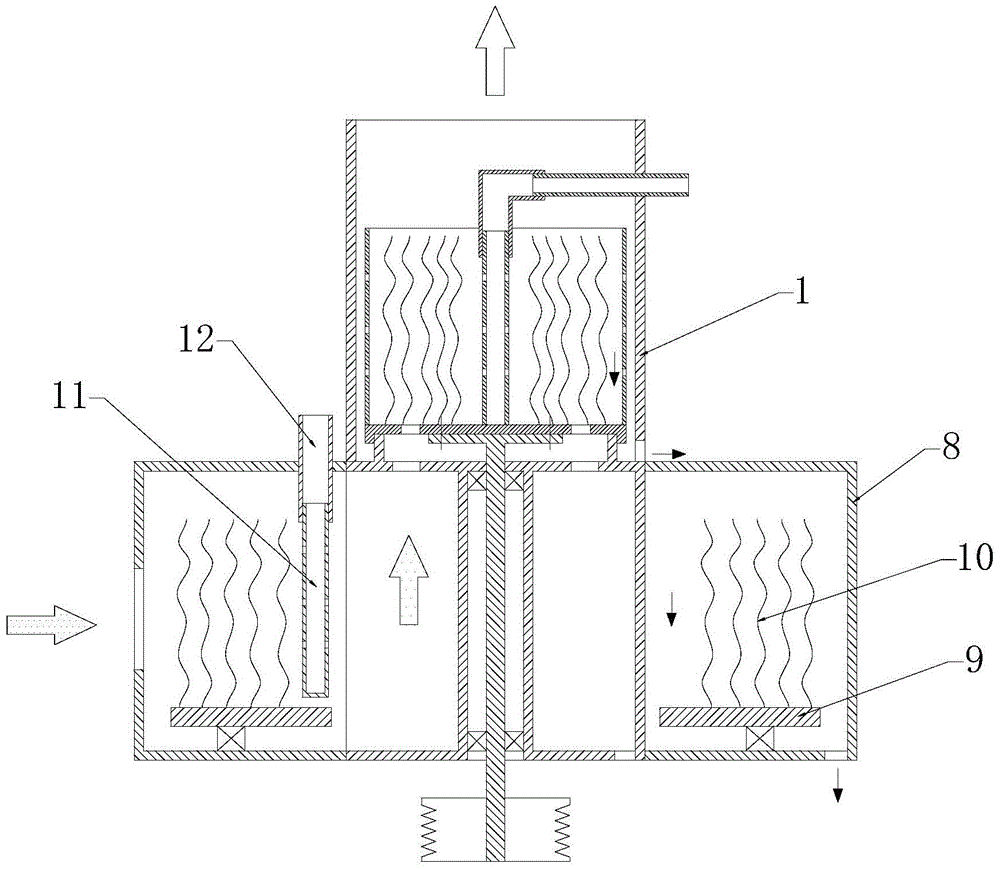

[0046] refer to figure 2 , figure 2 The hollow arrow indicates the gas flow direction, and the solid arrow indicates the flow direction of the liquid and particle mixture.

[0047] In order to further improve the removal efficiency of suspended particulate matter and nitrogen oxides and other harmful substances in the gas passing through the gas circulation channel, in this embodiment, the embodiment 1 is combined, and the gas purification equipment also includes a bottom shell 8 and a rotating plate 9 , the second centrifugal washing water dispersing device 10, the second water spraying device 11 and the second water inlet pipe 12;

[0048] The casing 1 is arranged in the bottom casing 8; a dust removal space is enclosed between the bottom casing 8 and the casing 1, and an air inlet is opened on the side wall of the bottom casing 8. The dust removal space communicates with the air inlet and the opening (gas inlet) on the side wall of the housing 1;

[0049] The rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com