Multilayer flip-flow screen type screening equipment

A technology of screening equipment and relaxation screen, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of blocked screen holes, the main frame of the screen machine does not vibrate, and the limitations of the comprehensive application of the screen machine. Effect of limited width and improved processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] A specific embodiment of the present invention will be described below in conjunction with the accompanying drawings.

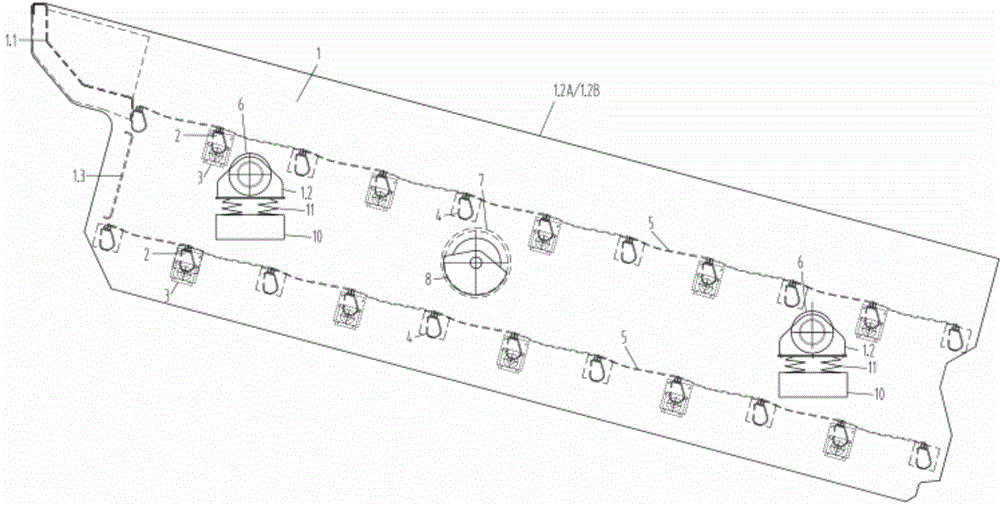

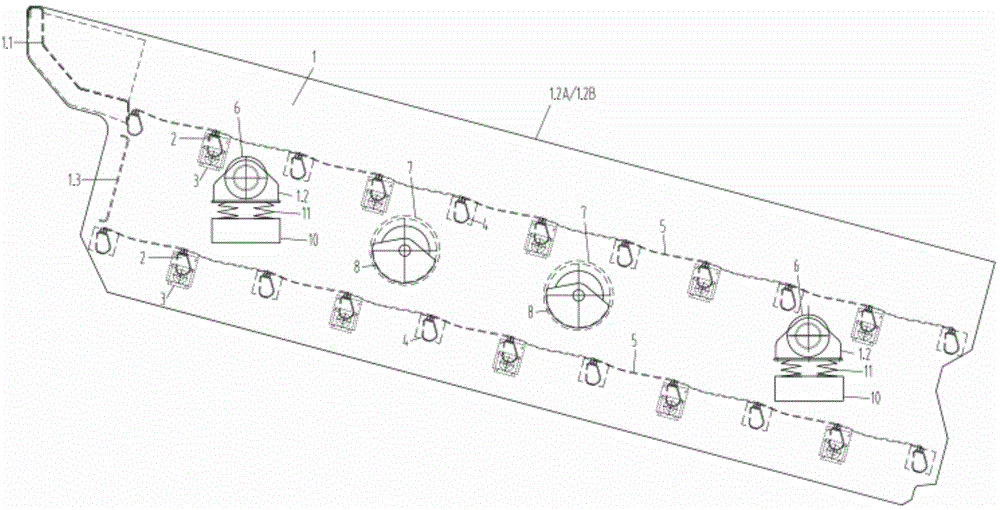

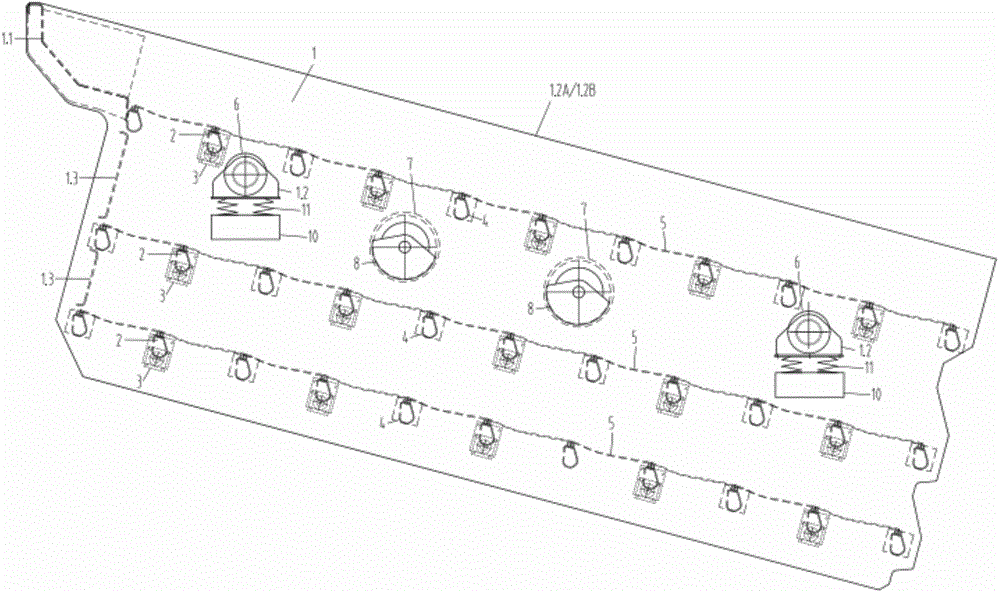

[0026] Such as Figure 1-4 As shown, the present invention provides a kind of multi-layer relaxation sieve type screening equipment, comprising a main vibrating body 1, the main vibrating body 1 is composed of a fixed beam 4, a supporting beam 6, an intermediate shaft protective sleeve beam 7, a feeding box 1.1, The left side plate 1.2A and the right side plate 1.2B are connected to form a frame structure, which is characterized in that it also includes a plurality of additional vibrating bodies, the additional vibrating bodies are fixed on the main vibrating body 1 through the swing seat 3, each The additional vibrating body is composed of a floating beam 2 and a swing seat 3 connected to the two ends of the floating beam 2. Each floating beam 2 is connected to the main vibrating body 1 through a swing seat 3. The fixed beam 4 and the floating beam 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com