Electric welding fixture capable of being controlled by one hand and provided with welding shielding lens and use method of electric welding fixture

A lens and handle technology, which is applied to the characteristics of welding rods, electrode support devices, and support devices for protection, etc., can solve problems such as inconvenience, and achieve the effect of simple use method, lightening labor intensity, and preventing direct exposure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below, the present invention will be further described in conjunction with the accompanying drawings and embodiments.

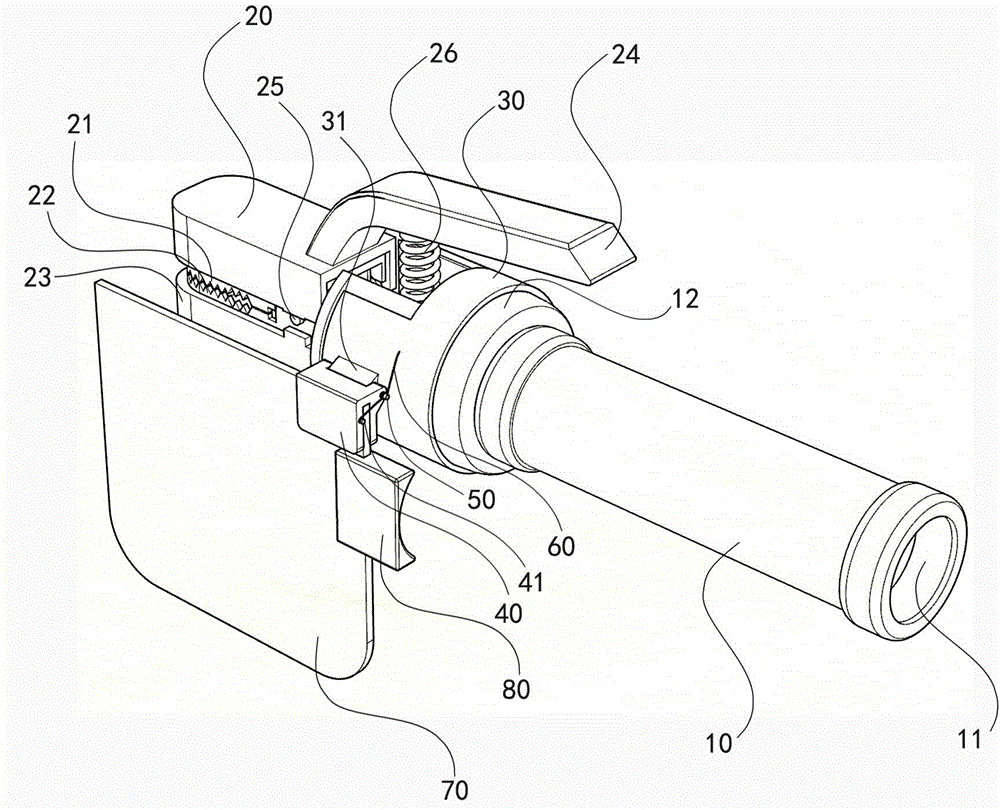

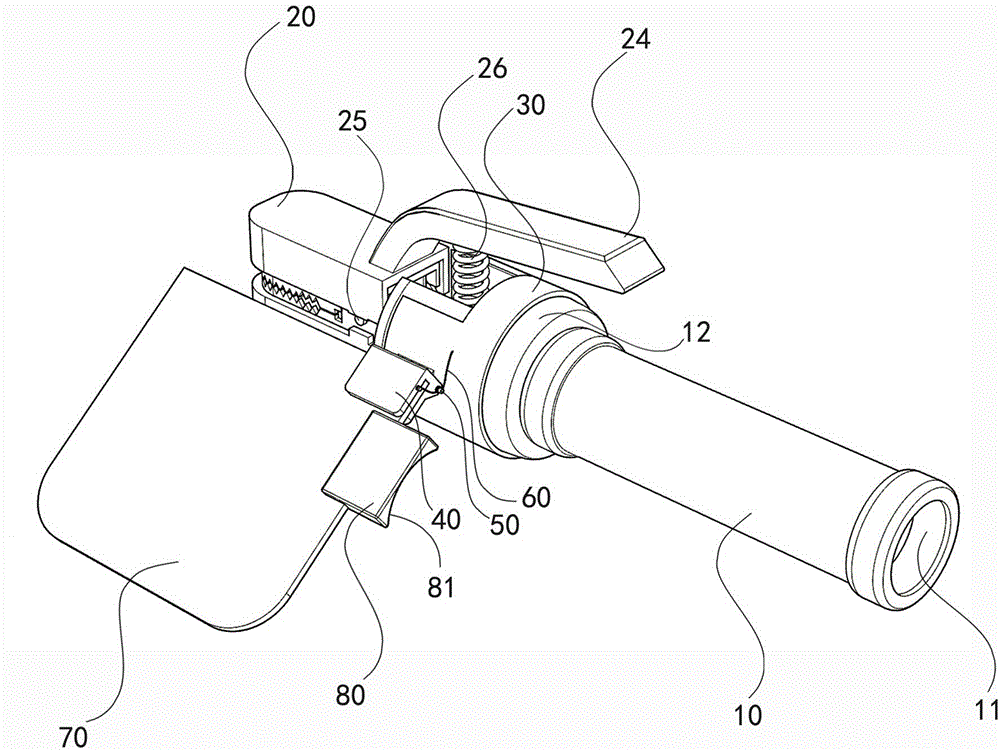

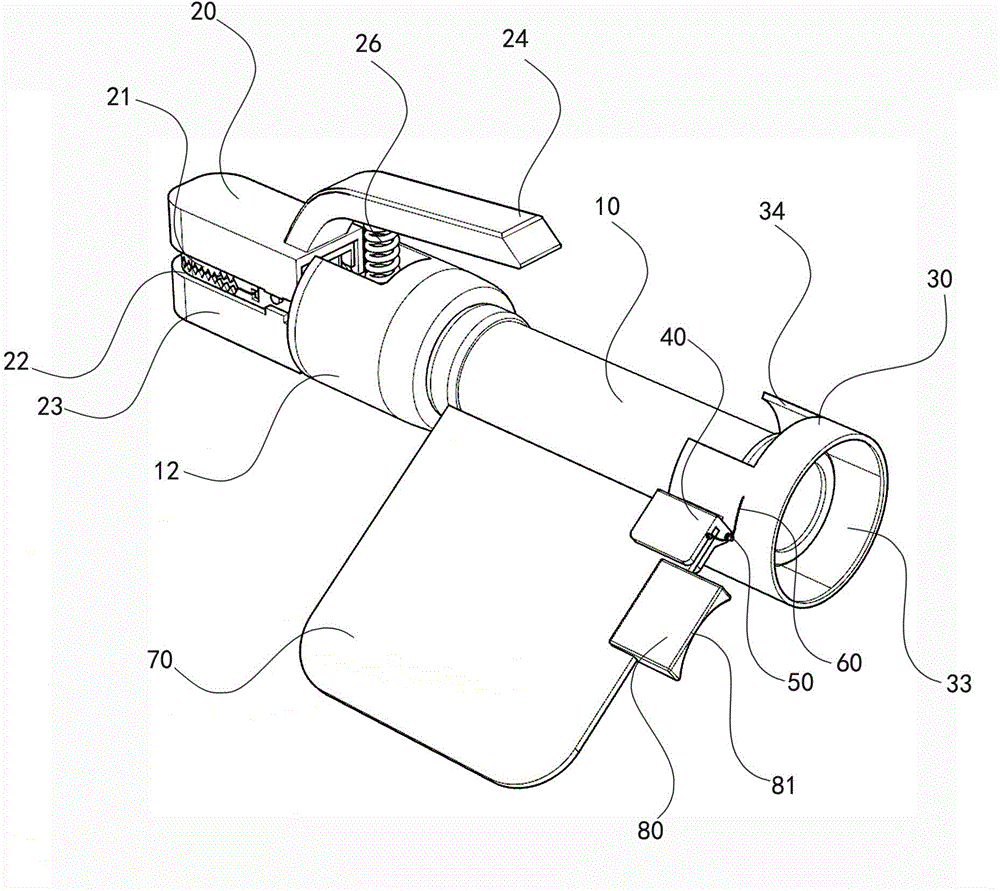

[0020] figure 1 — Figure 5 It is an embodiment of the present invention. As shown in the figure, a single-handed electric welding clamp with welding shading lens includes a handle 10, a wire guide hole 11, a front end of the handle 12, an upper insulating sleeve 20, and an upper copper tooth 21. , lower copper tooth 22, lower insulating sleeve 23, handle 24, large shaft pin 25, large spring 26; and ferrule 30 set on the handle front end 12; 33. Positioning block 40, spring clip 41, positioning block hole 42, positioning clip groove 43, limiting block 44, small shaft pin 50, small spring 60, positioning elbow 61, spring ring 62, tapered head 63, black Welding lens 70, side block 80, concave arc edge 81, side block clip groove 82; handle 10, wire guide hole 11, handle front end 12 and lower copper tooth 22 form a whole, and upper copper tooth 21 and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com