Pump body steel ball press machine

A pump body steel, ball pressure technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency and unreliable installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

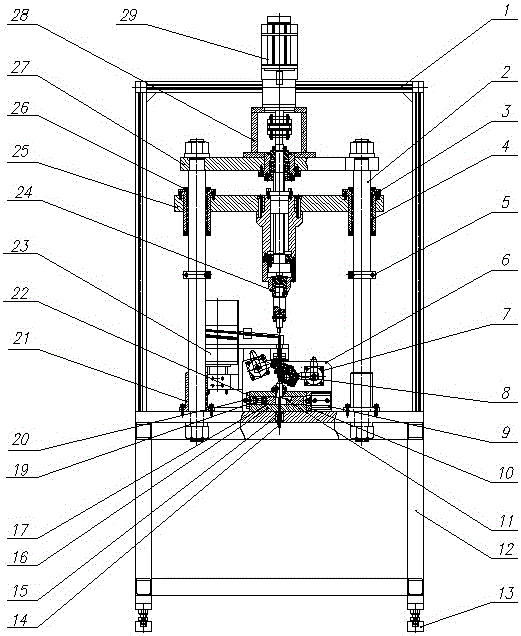

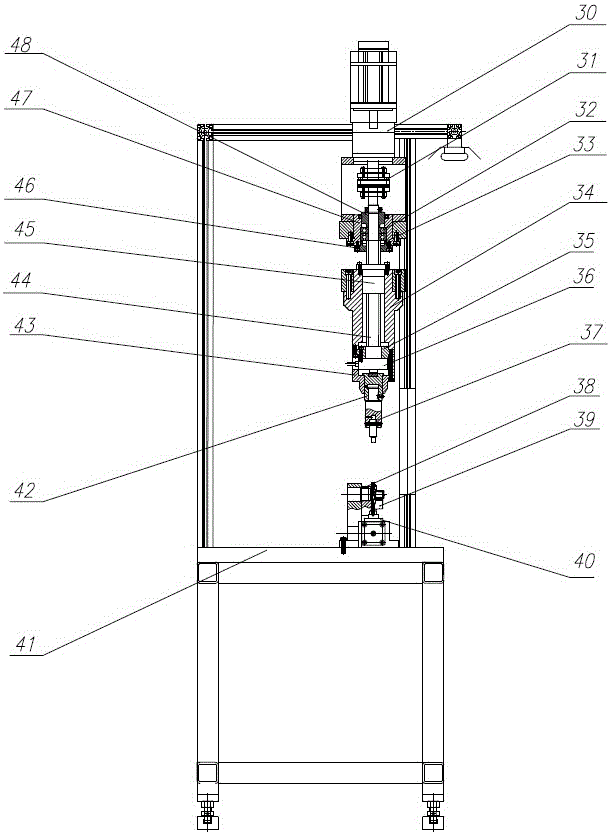

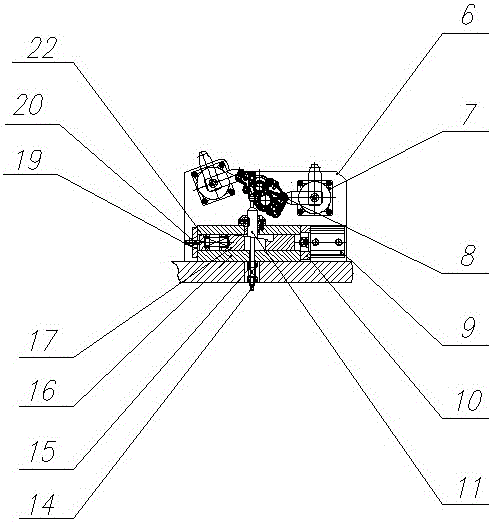

[0008] Specific implementation mode one: combine Figure 1-3 This embodiment will be described.

[0009] A pump body steel ball press-fitting machine, the equipment is a vertical structure, the machine tool table is composed of a bench 12, a work table 41 and a frame 1 on the table, and the bench 12 is equipped with four adjustable The foot 13 and the workbench are the main supporting parts of the equipment; the workpiece 39 is positioned through the positioning sleeve 38 and the positioning pin 8, and placed on the bottom plate of the fixture 6, and clamped by two clamping cylinders 7; the oil pump body is arranged on the fixture Bearing auxiliary support, the auxiliary support rod 11 can move up and down along the guide sleeve 40, the screw rod 14 is connected with the auxiliary support rod 11, the support spring 15 is installed on the screw rod 14, the wedge 17 is installed on the auxiliary support seat 16, and the locking spring Move left and right under the action of 22,...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination Figure 1-3 Describe the working process of the pump body steel ball press machine.

[0011] When the pump body steel ball press machine is working, the workpiece 39 is first placed on the positioning sleeve 38 and the pin 8, and clamped by the clamping cylinder 7, the auxiliary support rod 11 is in contact with the workpiece 39 under the action of the support spring 15, and the locking spring 22 make the auxiliary support rod 11 locked by the wedge 17. The steel ball automatic feeding device 23 makes the steel ball be transported to the correct position. Start the pressing machine, the motor 29 drives the reducer 30 to rotate the ball screw 44, and under the action of the screw nut 45, the moving plate 25 is driven to slide downward along the guide column 2, and the pressure head 37 presses the steel ball into the workpiece 39, and the steel ball After pressing in, the motor 29 reverses to make the press-fit mechanism ris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com