Stirring device for building materials

A technology for mixing devices and building materials, which is applied in the direction of cement mixing devices, clay preparation devices, chemical instruments and methods, etc. It can solve the problems of affecting the mixing effect of concrete, heavy blade weight, inconvenient installation, disassembly and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below by means of specific embodiments:

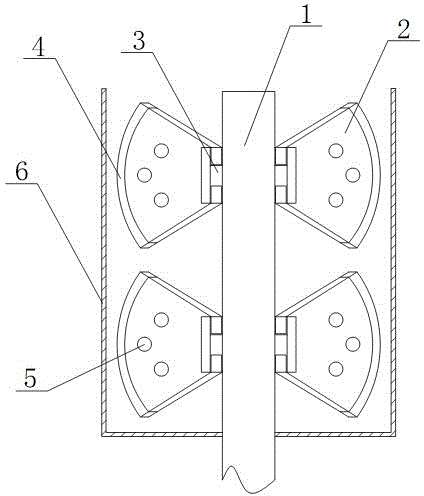

[0011] The reference numerals in the accompanying drawings of the specification include a stirring shaft 1 , a rotating blade 2 , a limit seat 3 , a rubber sheet 4 , a through hole 5 , and a hopper 6 .

[0012] The building material mixing device of embodiment is as attached figure 1 Shown: including the stirring shaft 1 and the rotating blade 2 set on the stirring shaft 1, the stirring shaft 1 cooperates with the reducer shaft of the power device, the stirring shaft 1 can be set as a circle or hexagonal, and the stirring shaft 1 is sleeved and fixed There are a plurality of spacer seats 3, and the material of the spacer seat 3 is preferably corrosion-resistant steel. 3. The connection with the stirring shaft 1 is fastened. At the same time, there is no need to slide along the axial direction of the stirring shaft 1 during disassembly, so it will not be affected by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com