A pull rod balancing device of a two-plate type injection molding machine

A balancing device and injection molding machine technology, applied in the field of injection molding, can solve the problems of increasing the axial size of the injection molding machine, increasing the production cost, etc., and achieve the effects of convenient control, prolonging the life of the oil cylinder, and reducing the wear and vibration of the tie rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

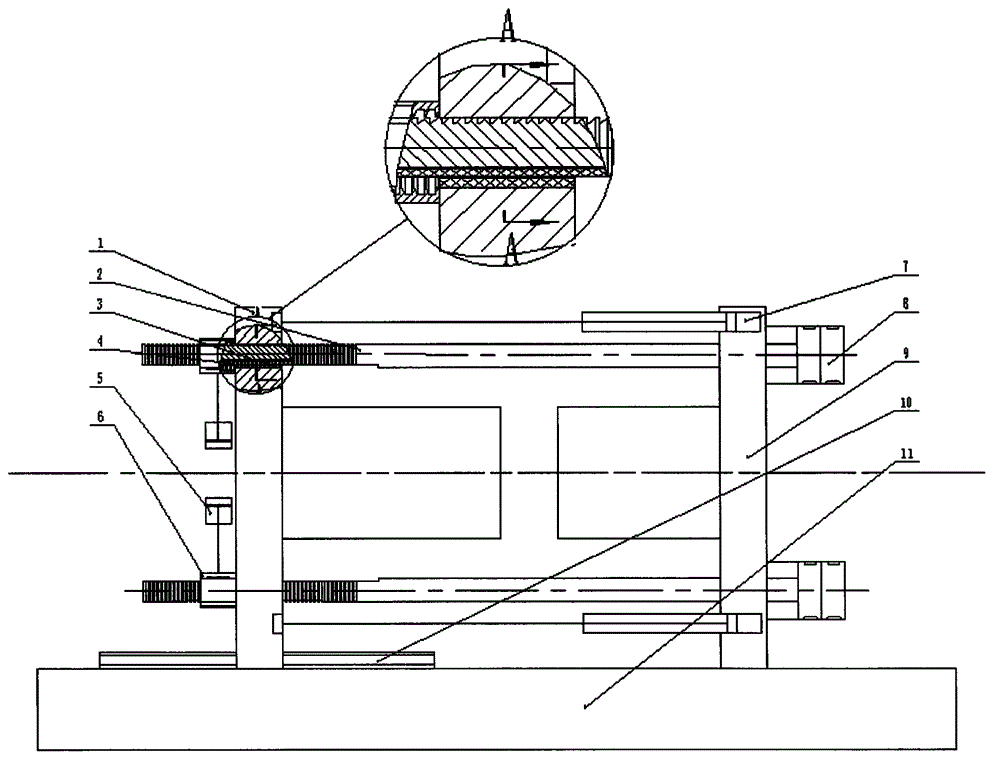

[0015] The present invention is a two-platen injection molding machine pull rod balance device, figure 1 As shown, the main part is composed of movable template 1, electromagnet one 3, electromagnet two 4, pull rod 2 and frame 11; One end of the tie rod 2 is connected to the piston rod of the clamping cylinder 8, the clamping cylinder 8 is fixed on the fixed platen 9, and the other end of the tie rod 2 is processed into a trapezoidal tooth groove and passes through the tie rod groove of the movable platen 1. Pull bar 2 has that section of trapezoidal tooth groove to mill out a plane axially, process a square groove in this plane, put into electromagnet 2 4 in the groove. The length of the square groove is determined by the mold opening distance of the movable template 1, as long as the square groove on the tie rod 2 is greater than the mold opening distance. The closing oil cylinder 5 is fixed on the movable template 1, and the piston rod of the closing oil cylinder 5 is conn...

Embodiment 2

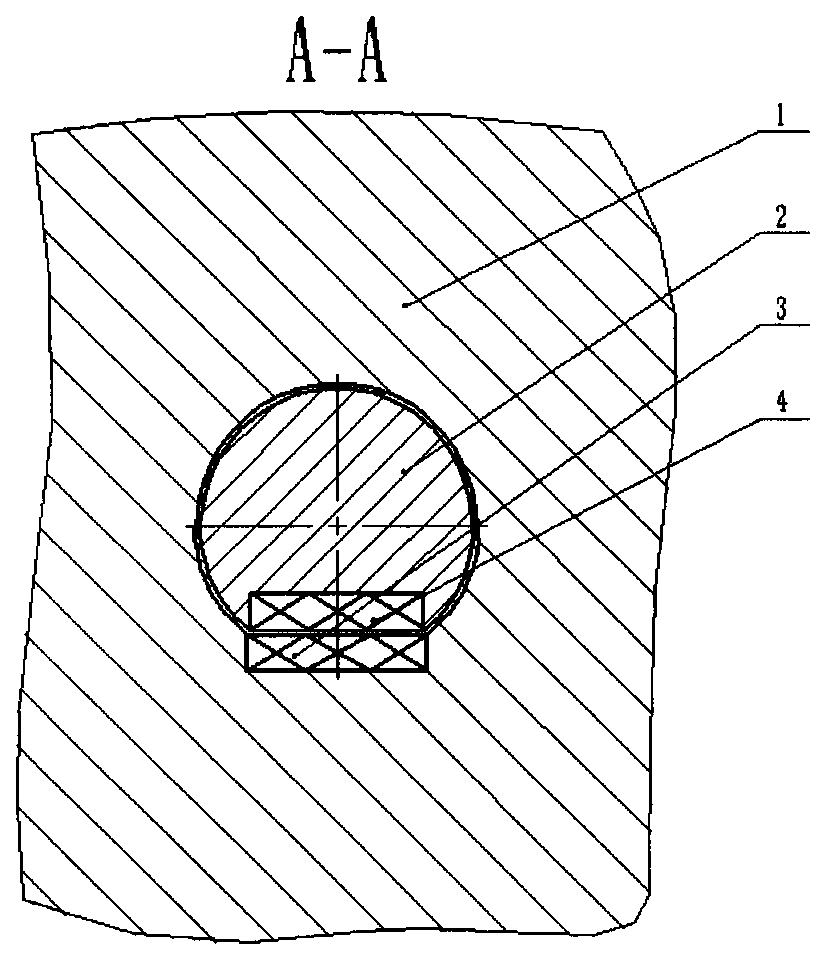

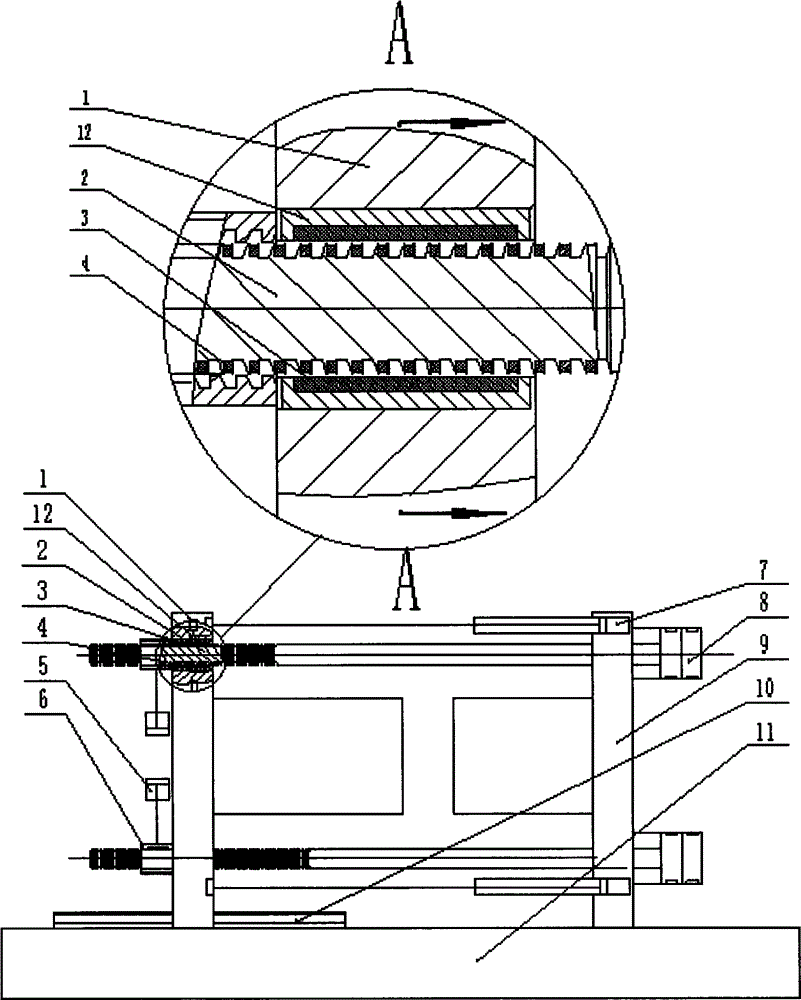

[0020] On the basis of Embodiment 1, an electromagnet sleeve 12 is fixed in the pull rod mounting hole of the movable template 1, and the electromagnet 3 is embedded in the electromagnet sleeve 12 along the circumferential direction, as image 3 , 4 As shown, four or more electromagnets 3 can be embedded in the circumferential direction of the electromagnet sleeve 12, and the electromagnet 4 is fixed at the corresponding position of the pull rod 2 and the electromagnet 3, that is, the trapezoidal convex teeth of the pull rod 2 are processed along the circumferential direction. Groove, electromagnet 2 4 is embedded in the groove of the trapezoidal convex teeth of pull rod 2, electromagnet 1 3 and electromagnet 2 4 have the same circumferential number and are installed in one-to-one correspondence, because the closer the distance between the two electromagnets, the greater the electromagnetic force, Therefore, the circumferential electromagnetic force not only overcomes gravity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com