Patents

Literature

75results about How to "Easy to program control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

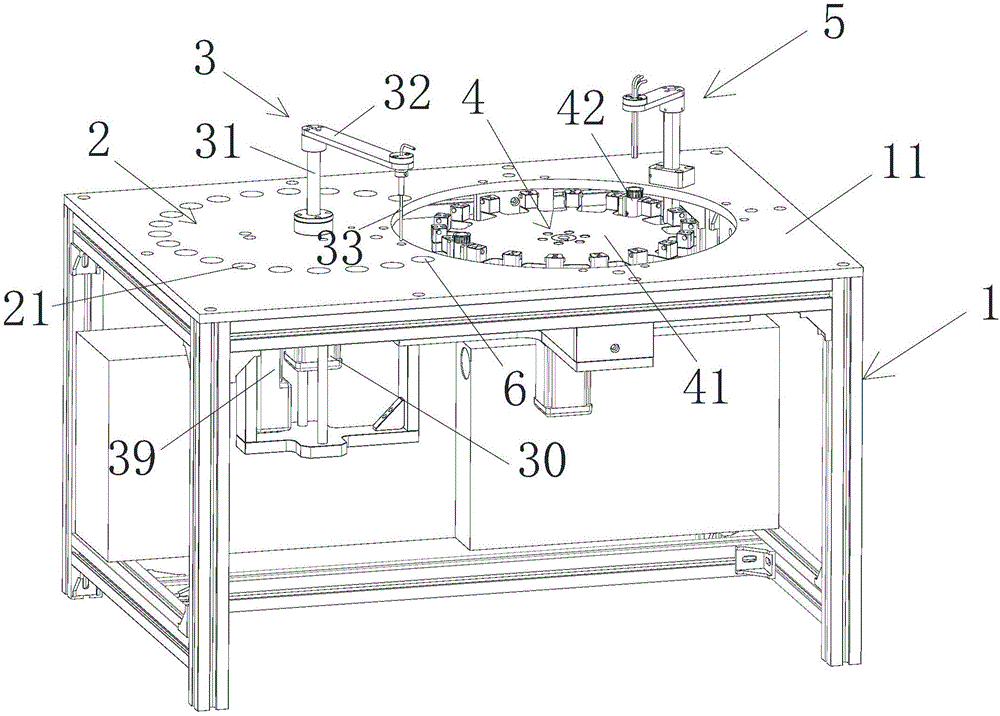

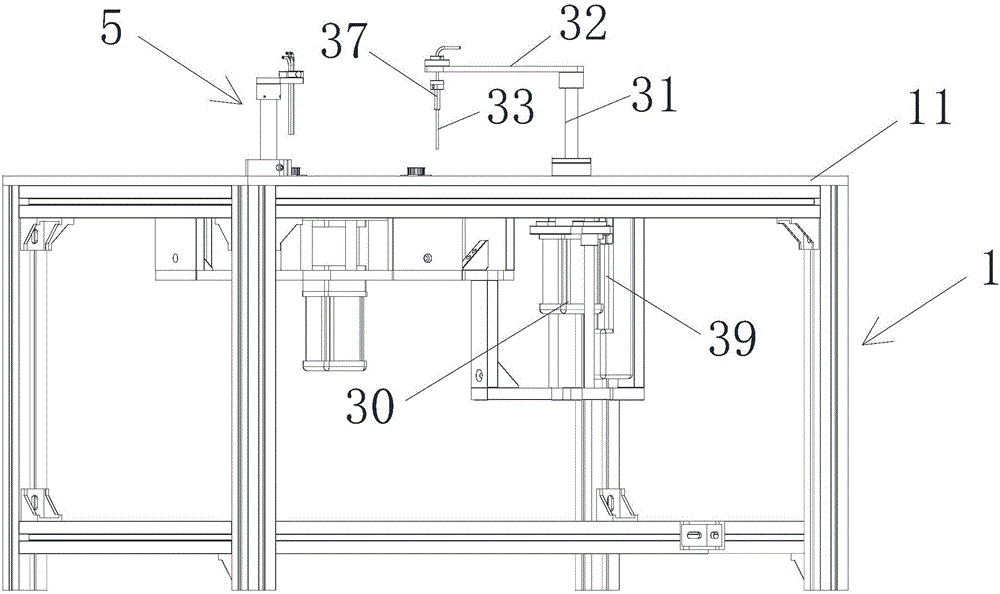

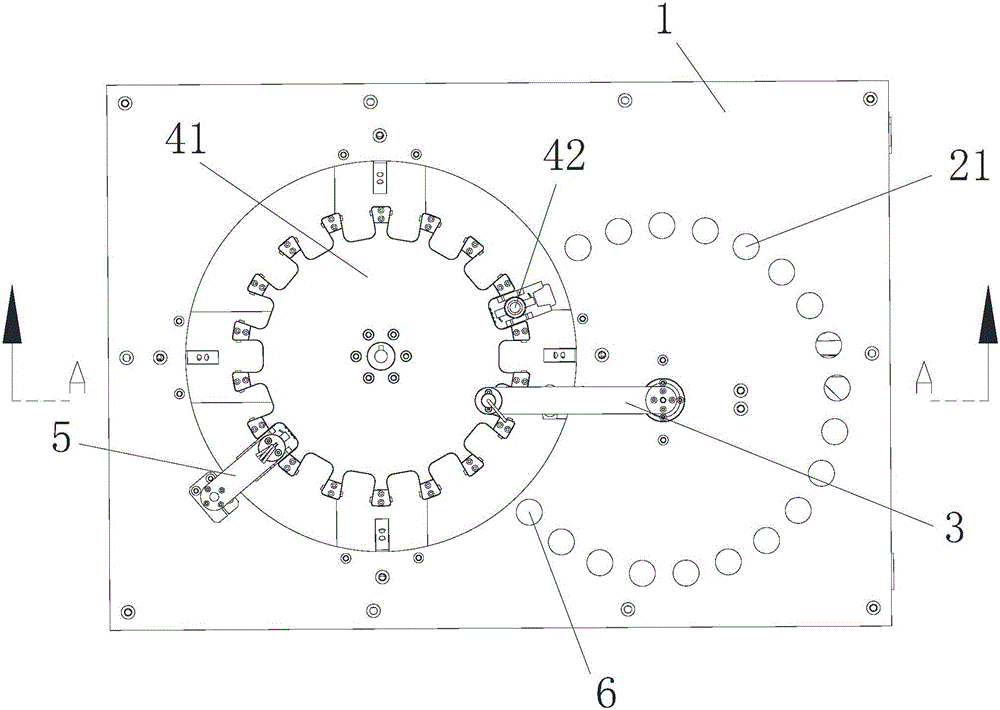

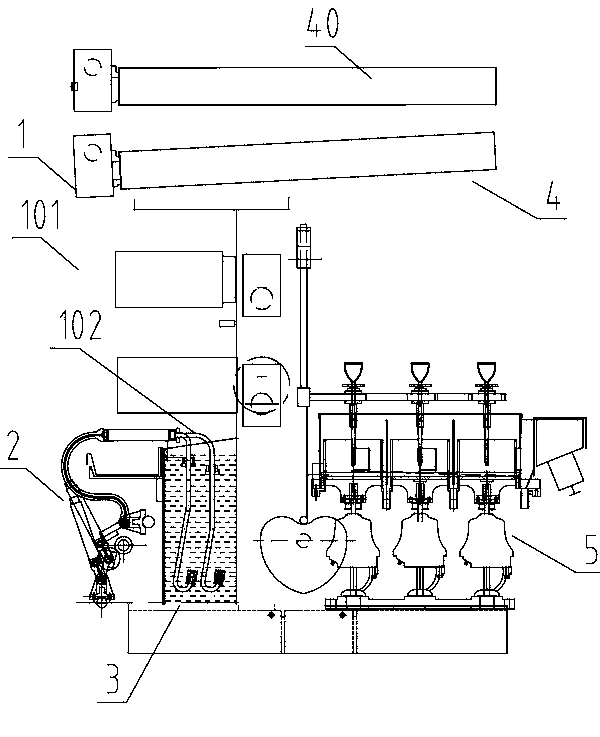

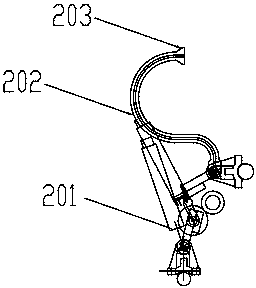

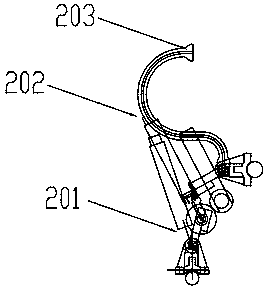

Fully automatic thinprep cytology processing and dyeing device

ActiveCN106018033ASimple structureReduce manufacturing costPreparing sample for investigationCytologyEngineering

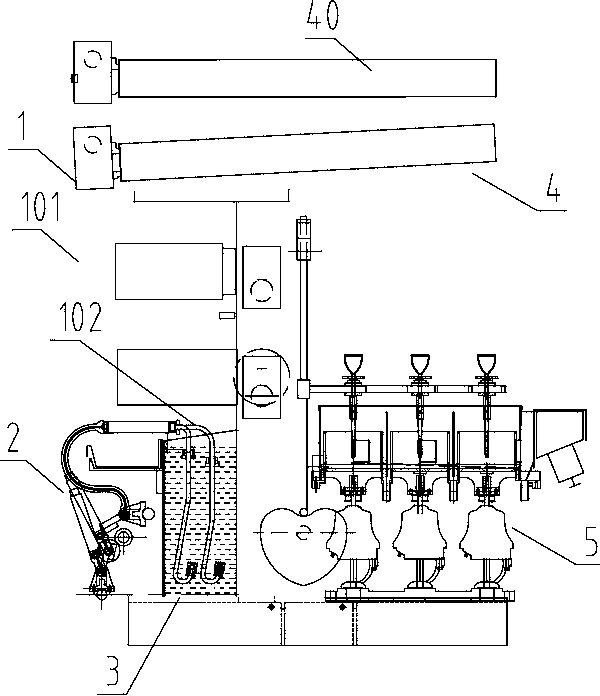

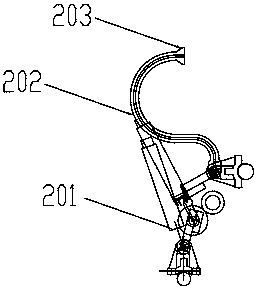

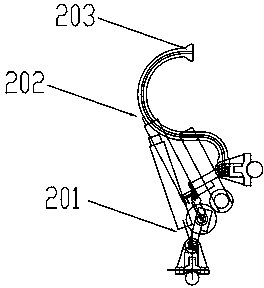

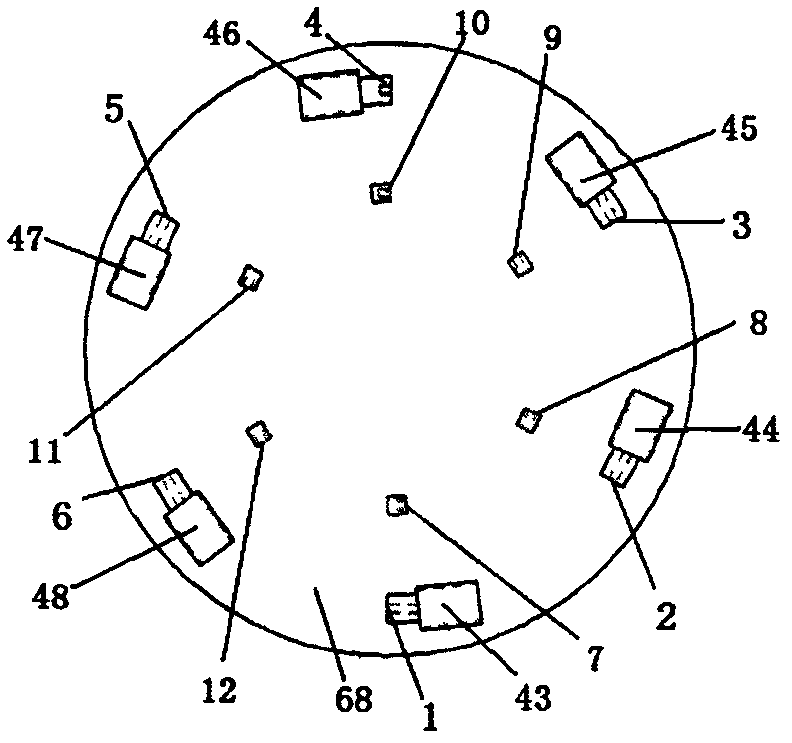

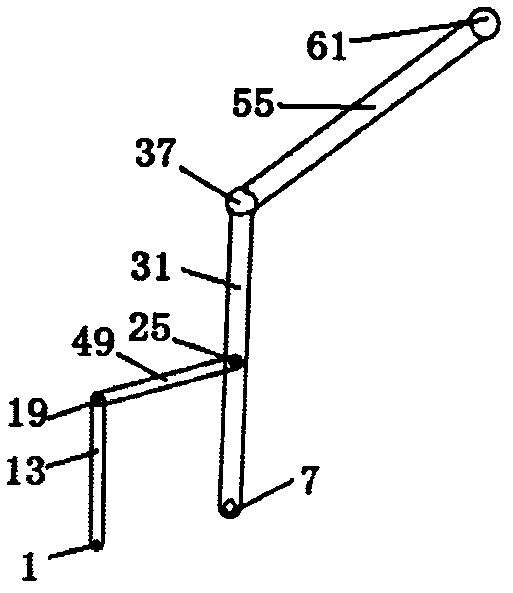

The invention relates to a fully automatic thinprep cytology processing and dyeing device, which comprises a rack, a sample placing area arranged on a platform of the rack, a pipetting mechanism arranged in the sample placing area, a processing mechanism arranged beside the sample placing area, and a dyeing mechanism. The objective of the invention is to provide a fully automatic thinprep cytology processing and dyeing device. The fully automatic thinprep cytology processing and dyeing device provided by the invention has the advantages that 1, a circular region formed by the processing mechanism is intersected with or tangent to the sample placing area, the pipetting mechanism is arranged at the center of a circle of the sample placing area, the sampling, liquid adding, cleaning, waste liquid absorbing and other operations can be completed by one pipetting mechanism, the whole structure is simplified, and the manufacturing cost is saved; 2, the pipetting mechanism is provided with a cleaning assembly A for washing the inner tube wall of an inner suction tube, an outer also sleeves the inner suction tube, and a cleaning assembly B is matched, so that the outer tube wall of the inner suction tube can be washed, and thus the pollution preventing effect is achieved.

Owner:三明市贝真生物科技有限公司

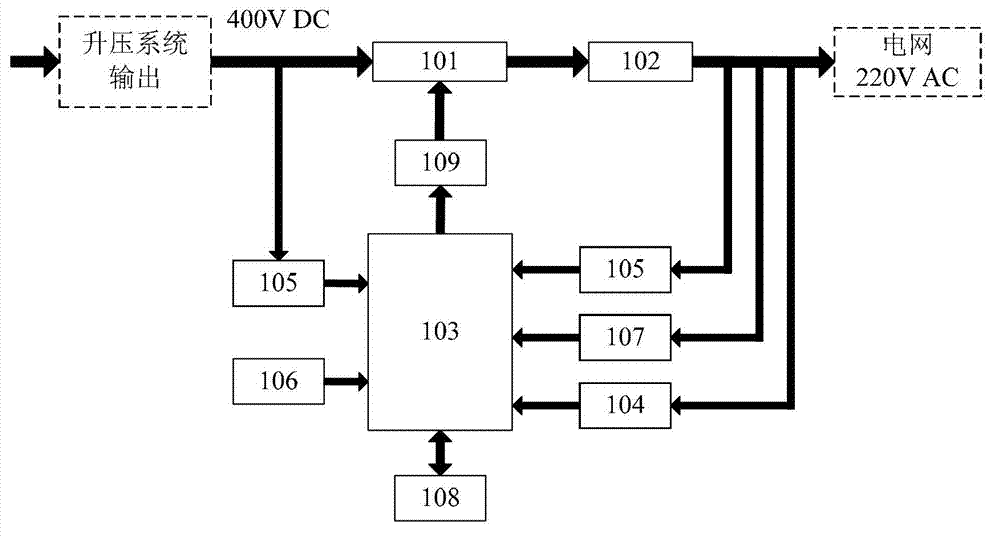

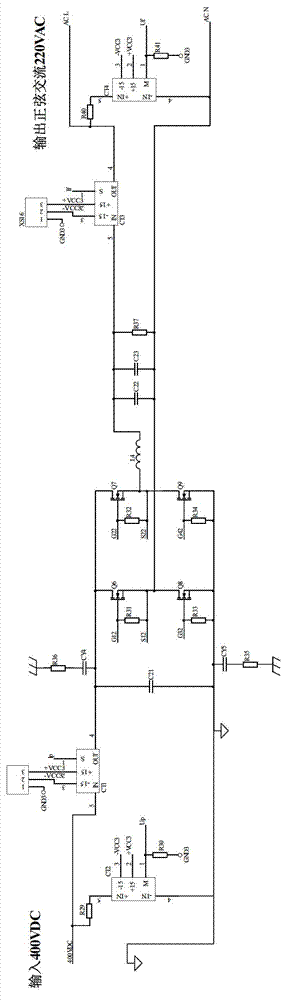

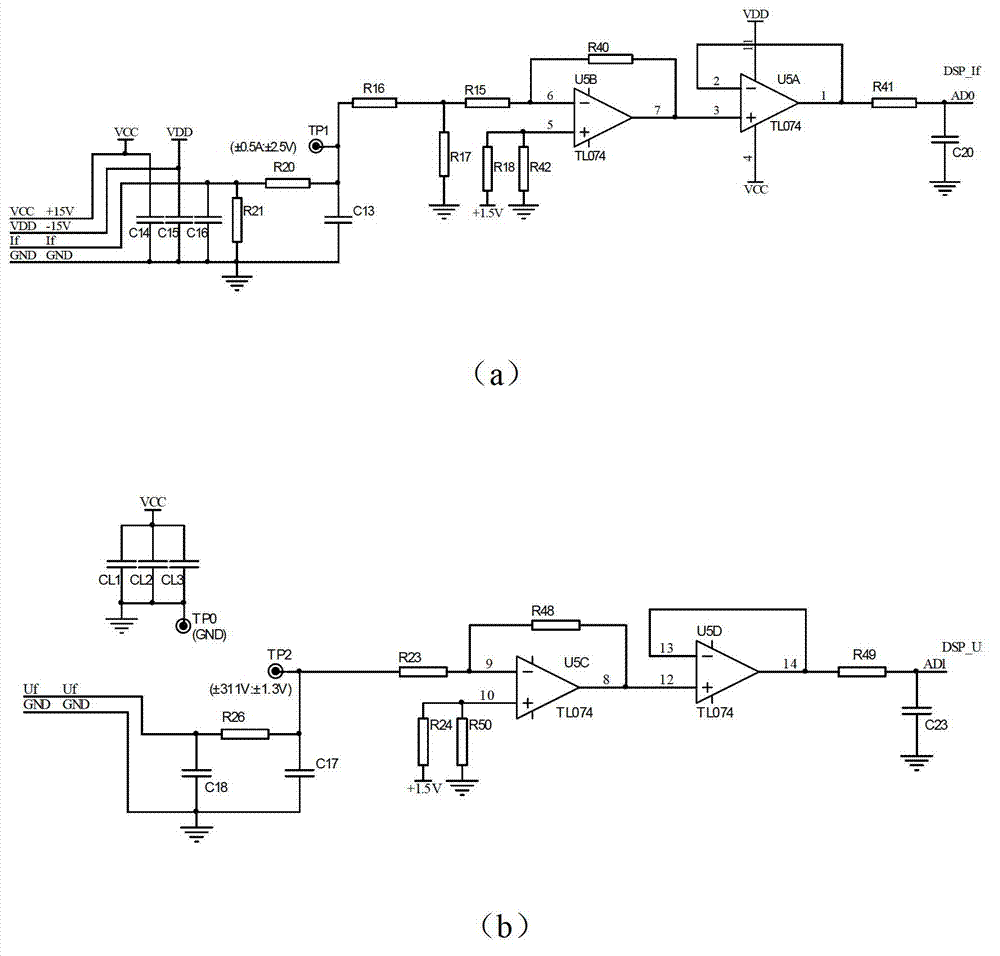

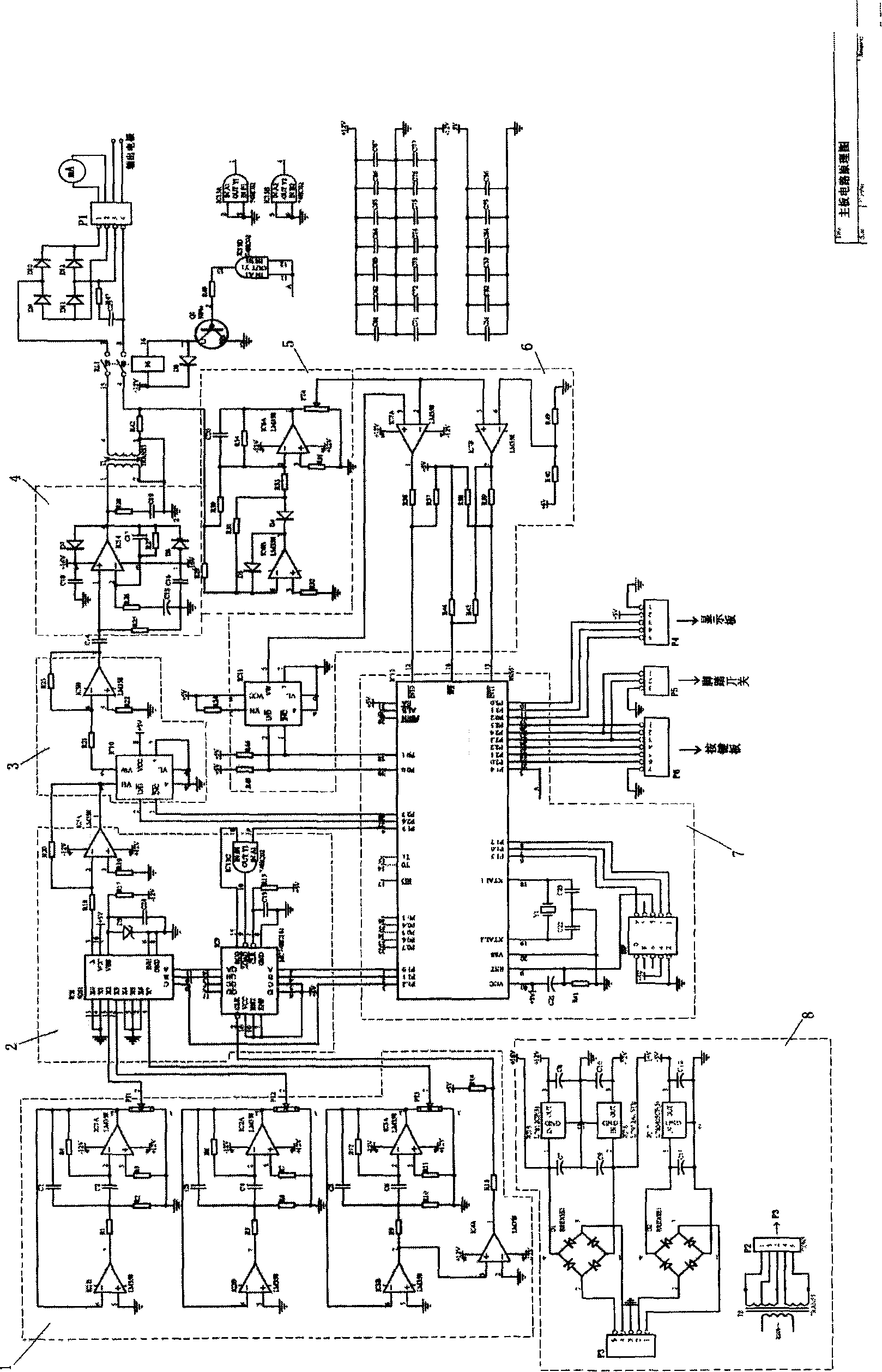

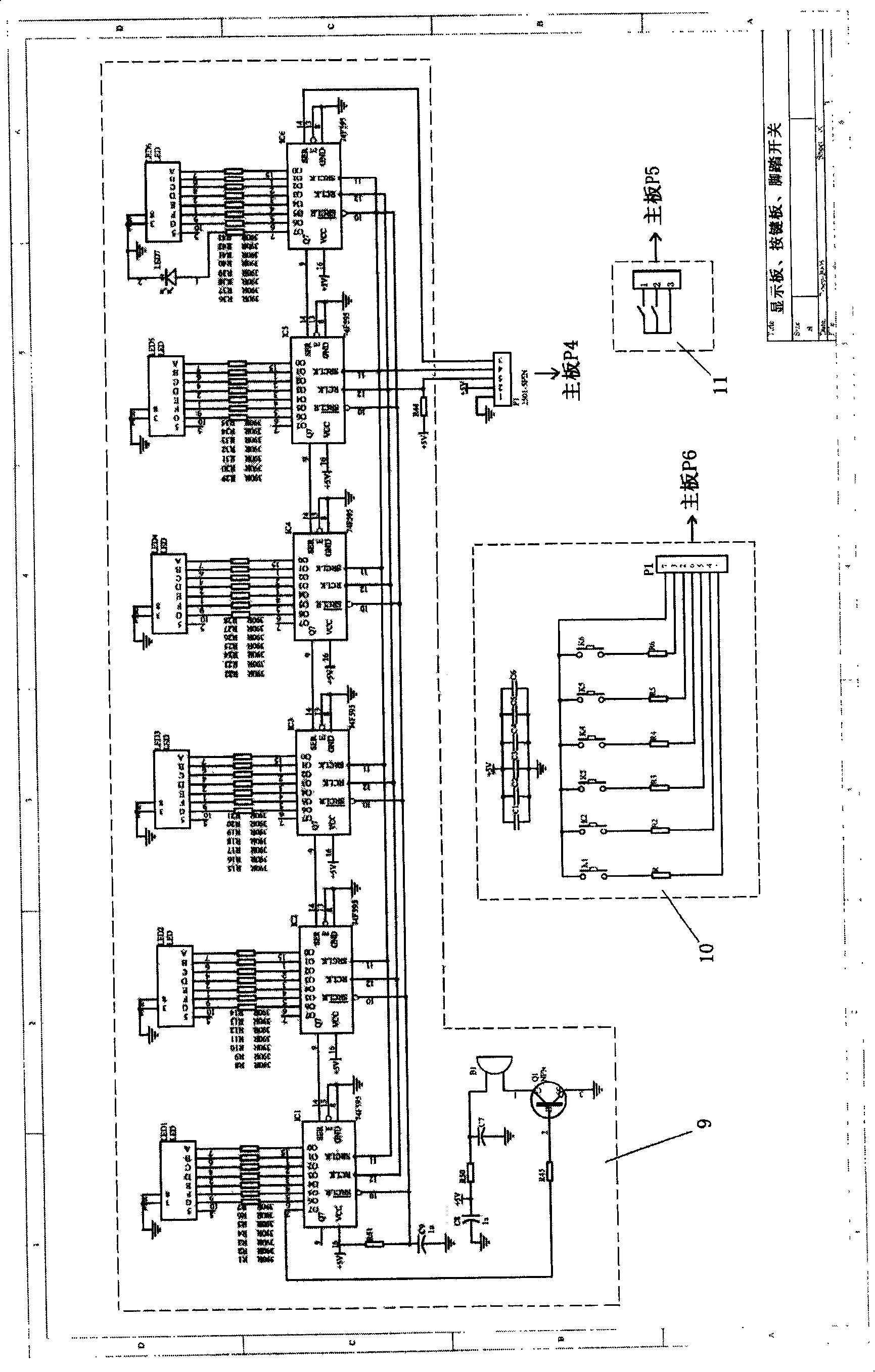

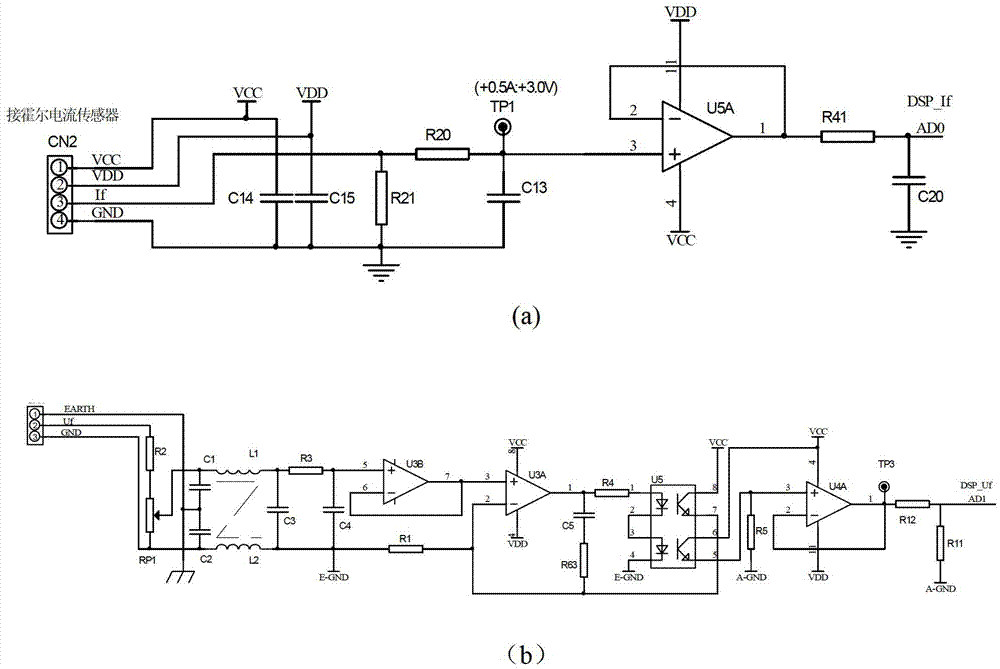

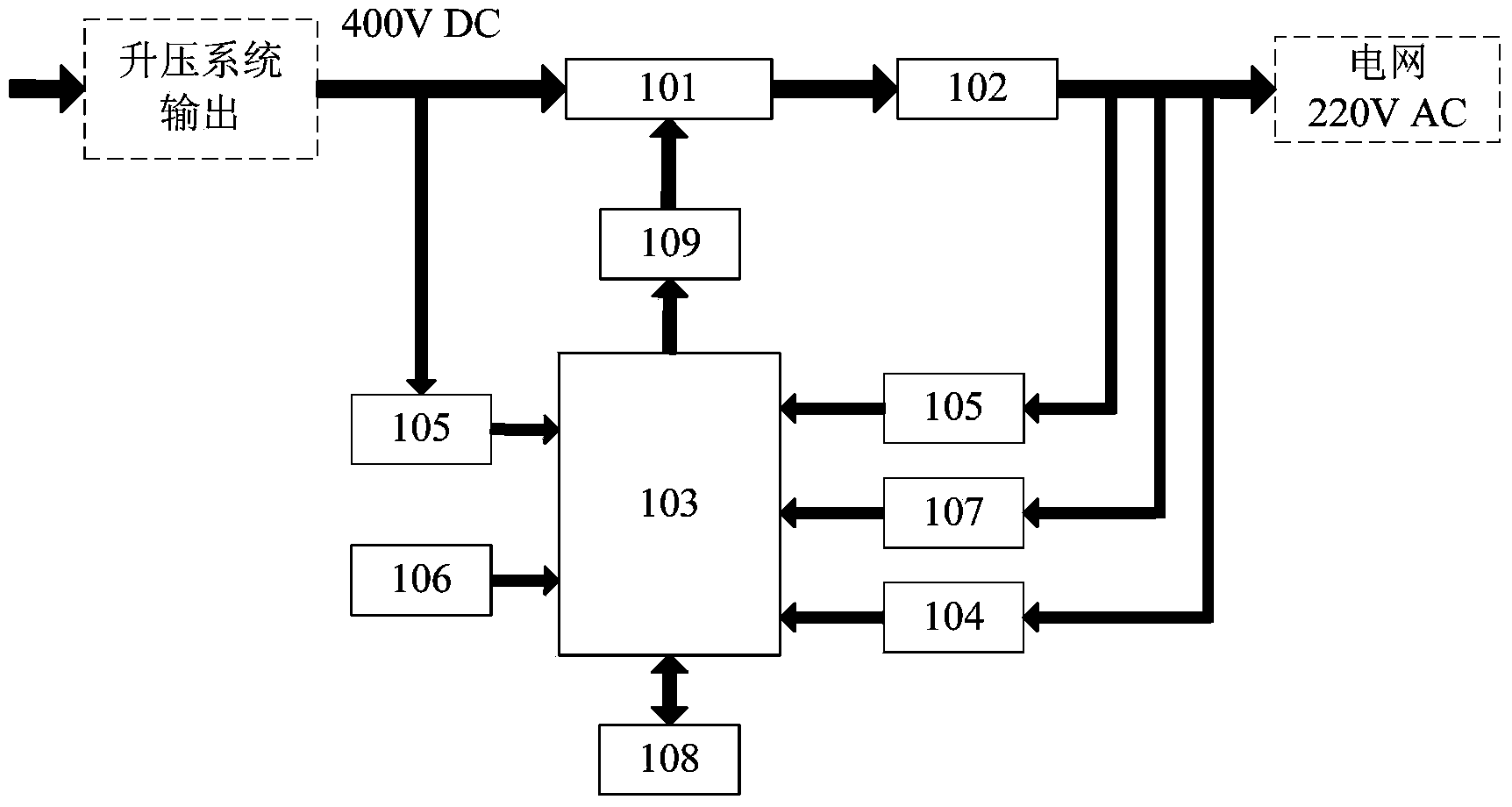

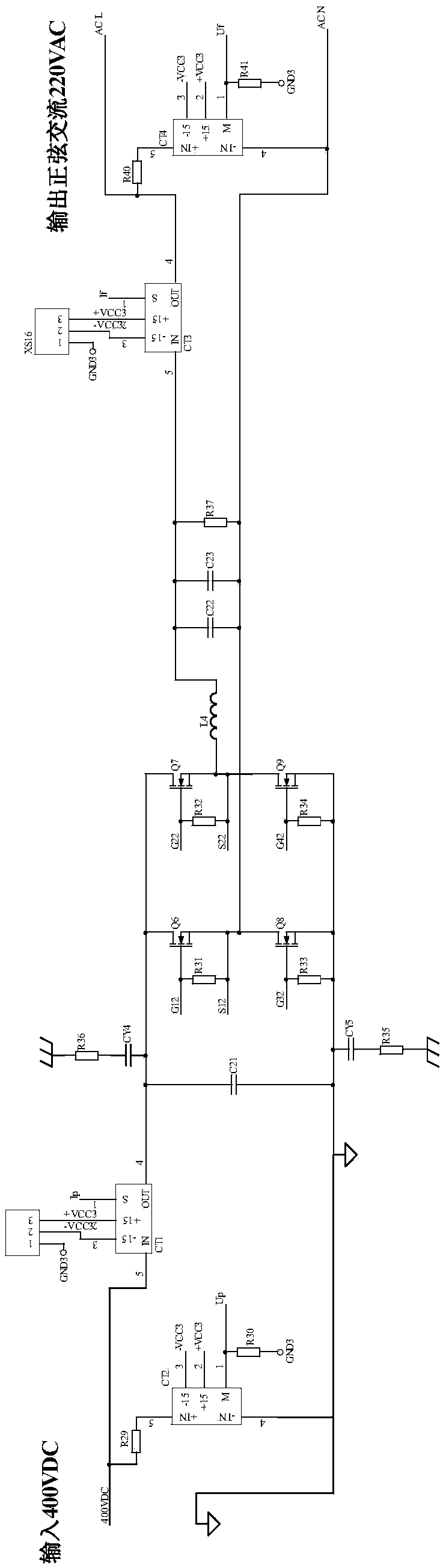

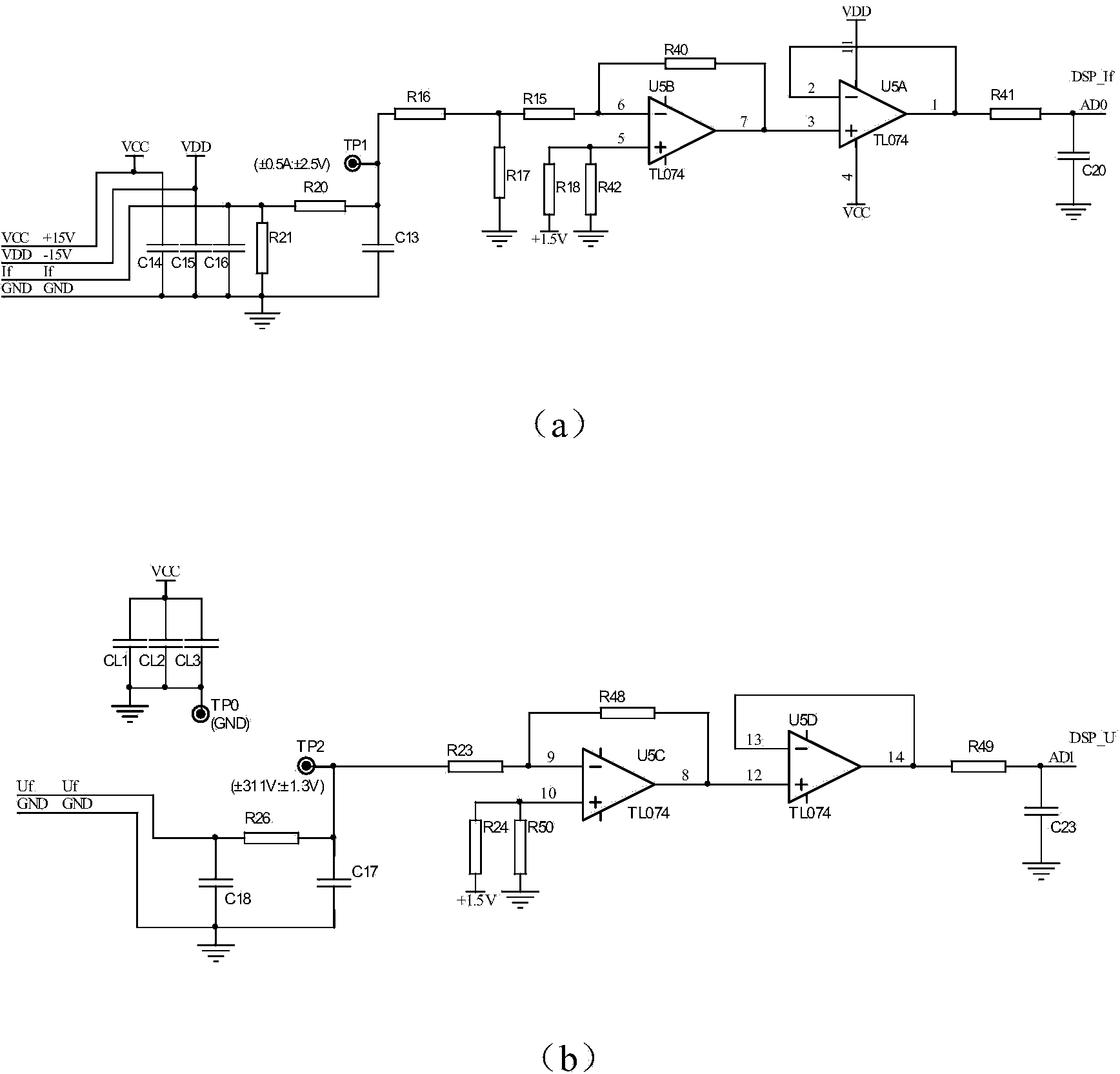

DSP (digital signal processor) based energy-feedback electronic load grid-connected inverting system and control method thereof

InactiveCN102832639AImprove consistencyImprove good performanceEfficient power electronics conversionAc-dc conversionDigital signal processingElectronic load

The invention discloses a DSP (digital signal processor) based energy-feedback electronic load grid-connected inverting system and a control method thereof. The system comprises a main circuit and a control circuit. The main circuit comprises a grid-connected inverting module and an output filter module in sequential connection, the grid-connected inverting module is connected with a 400V DC (direct-current) output end of a booster system, the output filter module is connected with a public power grid phase, and the control circuit comprises a fault protection circuit module, a current voltage sampling and signal processing module, a human-computer interaction module, a DSP embedded system module and a high-frequency driving module. Fully digitalized control of the grid-connected inverting system is realized by a reliability test aiming at low-voltage direct-current power output characteristics for the first time in China, on the basis of the high-frequency PWM (pulse-width modulation) technology and adopting an industrial-level high-performance digital signal processor DSP chip, 400V high-voltage direct-current output by the energy-feedback electronic load booster system is inverted into 220V single-phase power-frequency current, and an output side is connected into a power grid.

Owner:SOUTH CHINA UNIV OF TECH

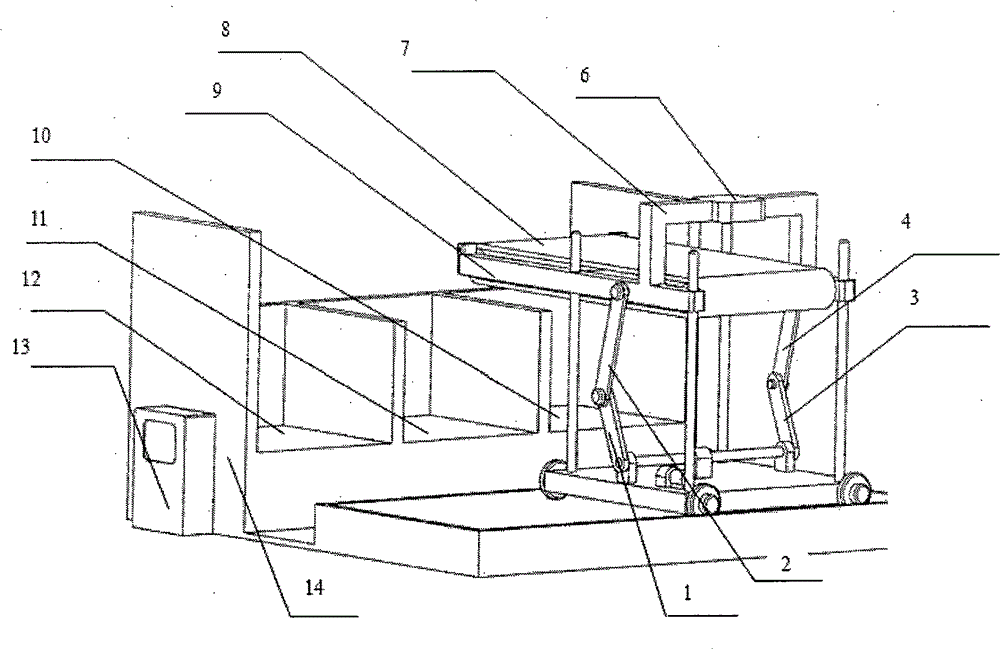

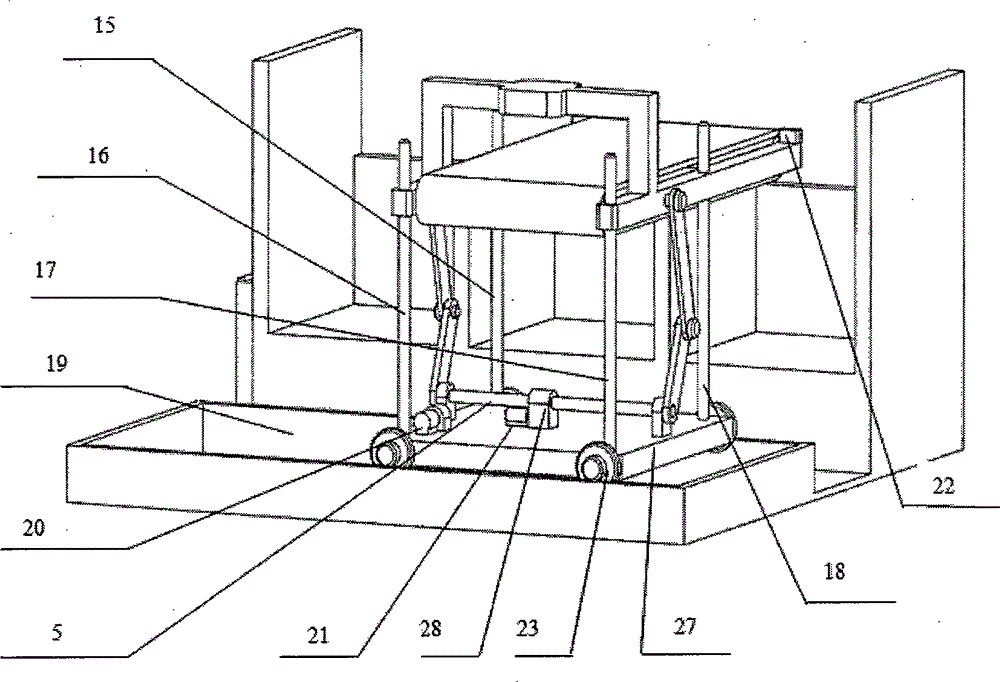

Automatic sorting machine for books in libraries

InactiveCN104670782AFit closelyBook location information correspondenceStorage devicesControl systemEngineering

The invention discloses an automatic sorting machine for books in libraries. The automatic sorting machine comprises a bookshelf, a control system, a scanner, motors, a sensor, a conveying mechanism, a lifting mechanism, a moving mechanism and a guide rail. The books are arranged on a conveyor belt below the scanner, position information on the books can be scanned by the scanner, the first motor can be started under the control of the control system, a third wheel and a fourth wheel can be driven by the first motor, accordingly, the moving mechanism reaches specified positions, the first motor is stopped, the second motor is instantly started by the control system and drives the lifting mechanism to ascend and descend, book arranging heights of the specified positions can be detected by the sensor, the second motor is stopped under the control of the control system, the third motor is instantly started under the control of the control system and drives a first conveyor belt guide wheel, and the conveyor belt can be driven to place the books into the specified positions. The automatic sorting machine for the books in the libraries has the advantages that the automatic sorting machine is high in practicality, operation efficiency and response speed and good in flexibility, and can be widely applied to the libraries.

Owner:GUANGXI UNIV

Spinning technology of two-spinning-roller semicontinuous high-speed spinning machine

InactiveCN103409824AReduce in quantityReduce manufacturing costArtificial thread manufacturing machinesWet spinning methodsSpinningMachine

The invention relates to a spinning technology of a two-spinning-roller semicontinuous high-speed spinning machine, and belongs to the technical field of semicontinuous spinning machines. The spinning technology comprises the steps of glue supplying, thread-line forming, spinning and winding, wherein the spinning is carried out through a spinning device. The spinning device comprises two spinning rollers which are transversely arranged relative to an operating surface of a spun surface, thread lines surround the spinning rollers, and drafting, solidifying and deacidification in the spinning steps are achieved when the spinning rollers rotate. The spinning technology solves the problems that thread lines of a semicontinuous spinning machine in the prior art are insufficient in reaction, the spinning process cannot be accelerated, and production efficiency and the product quality cannot be taken into consideration. The arrangement direction of the spinning rollers is changed so that the thread lines can walk for a longer distance while the spinning process of the spinning machine is accelerated and the structures of other components of original equipment are not changed, the thread lines can be reacted with acid bath more fully, and both production efficiency and product quality are taken into consideration.

Owner:YIBIN HIEST FIBER +2

Controllable mechanism type parallel robot platform with six degrees of freedom

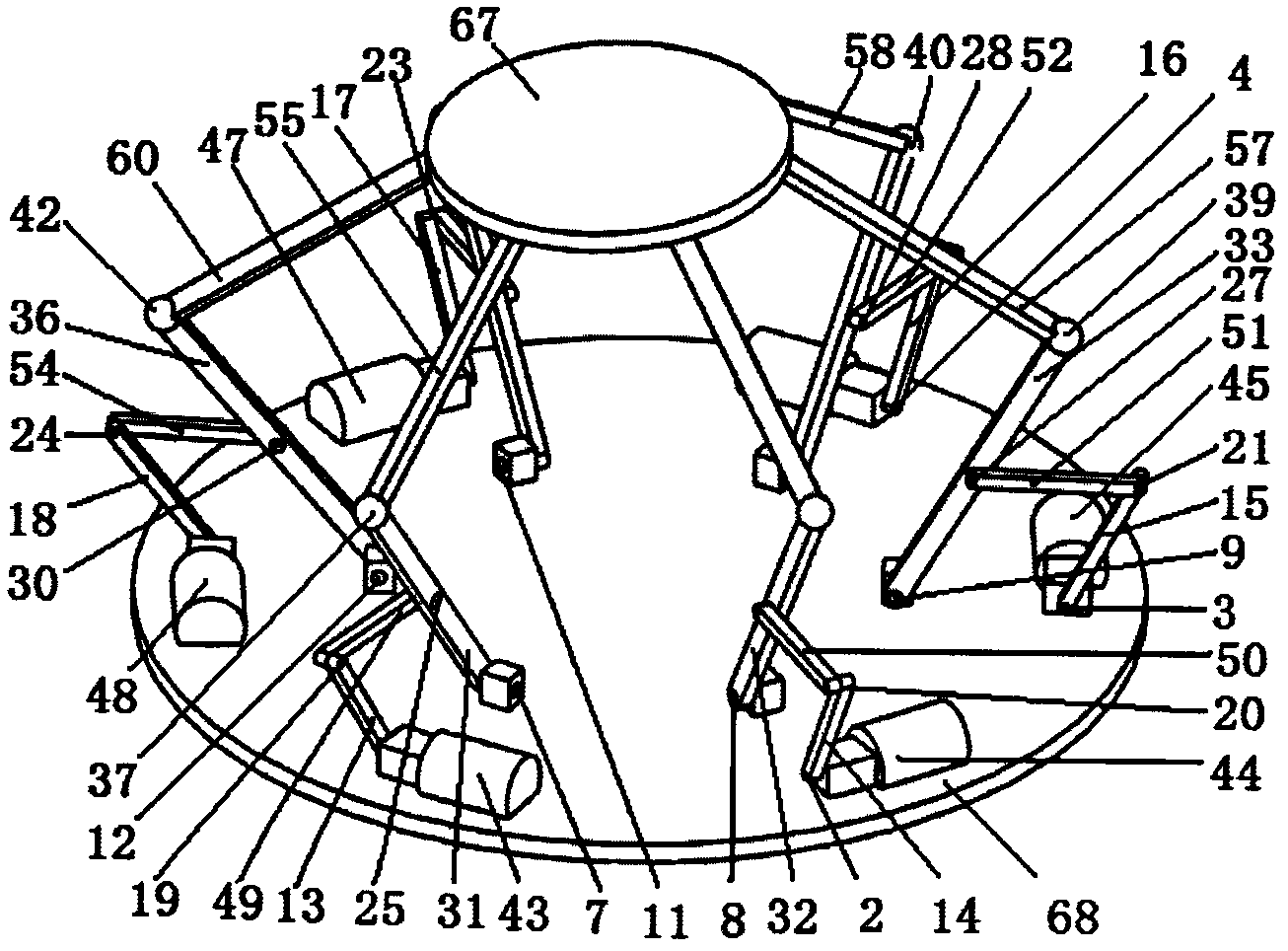

InactiveCN102528796AIncrease stiffnessImprove mechanical propertiesProgramme-controlled manipulatorDegrees of freedomMulti degree of freedom

A controllable mechanism type parallel robot platform with six degrees of freedom comprises a fixed platform, a movable platform and six branched chains. The fixed platform and the movable platform of the robot platform are connected by the six branched chains, and the six branched chains are respectively driven by six servo motors mounted on the fixed platform. The robot platform has the six degrees of freedom and is high in flexibility, carrying capacity of the robot platform is high due to the fact that the various servo motors are mounted on the fixed platform, and the controllable mechanism type parallel robot platform can be widely applied to places with multi-degree-of-freedom experiment platforms, antenna pedestals, machine tools, flight simulators and the like.

Owner:GUANGXI UNIV

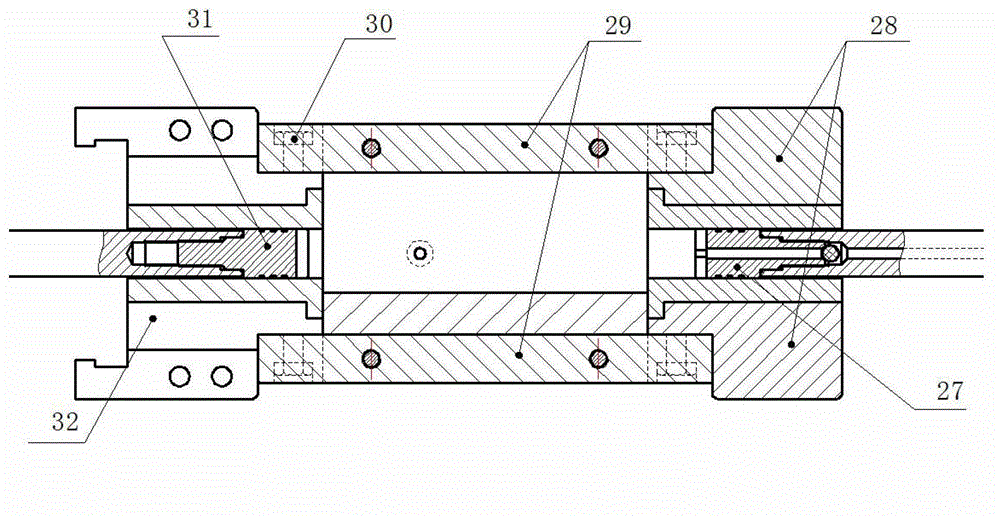

Continuous mobile waterpower drive device of nuclear reactor control rod

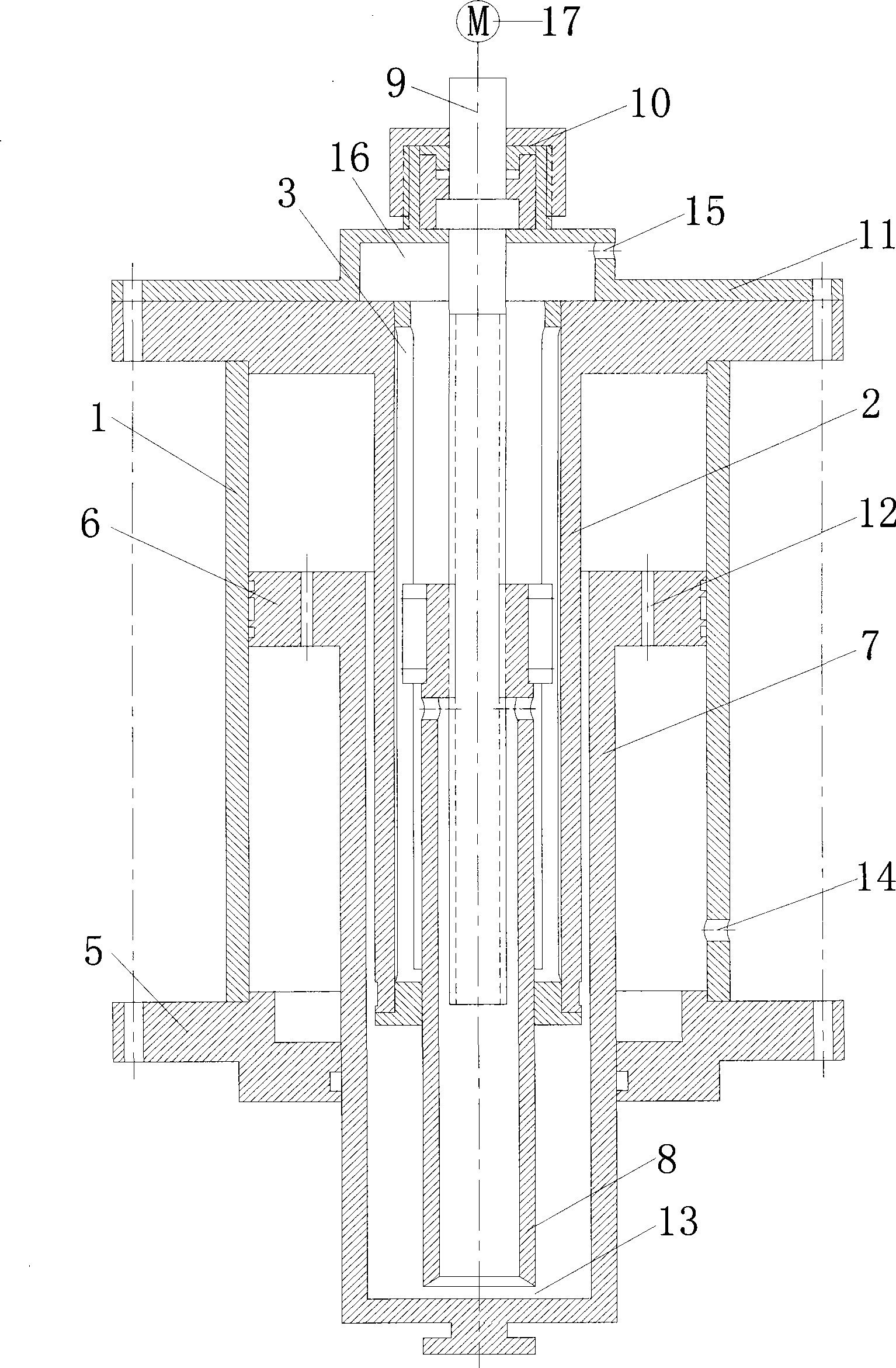

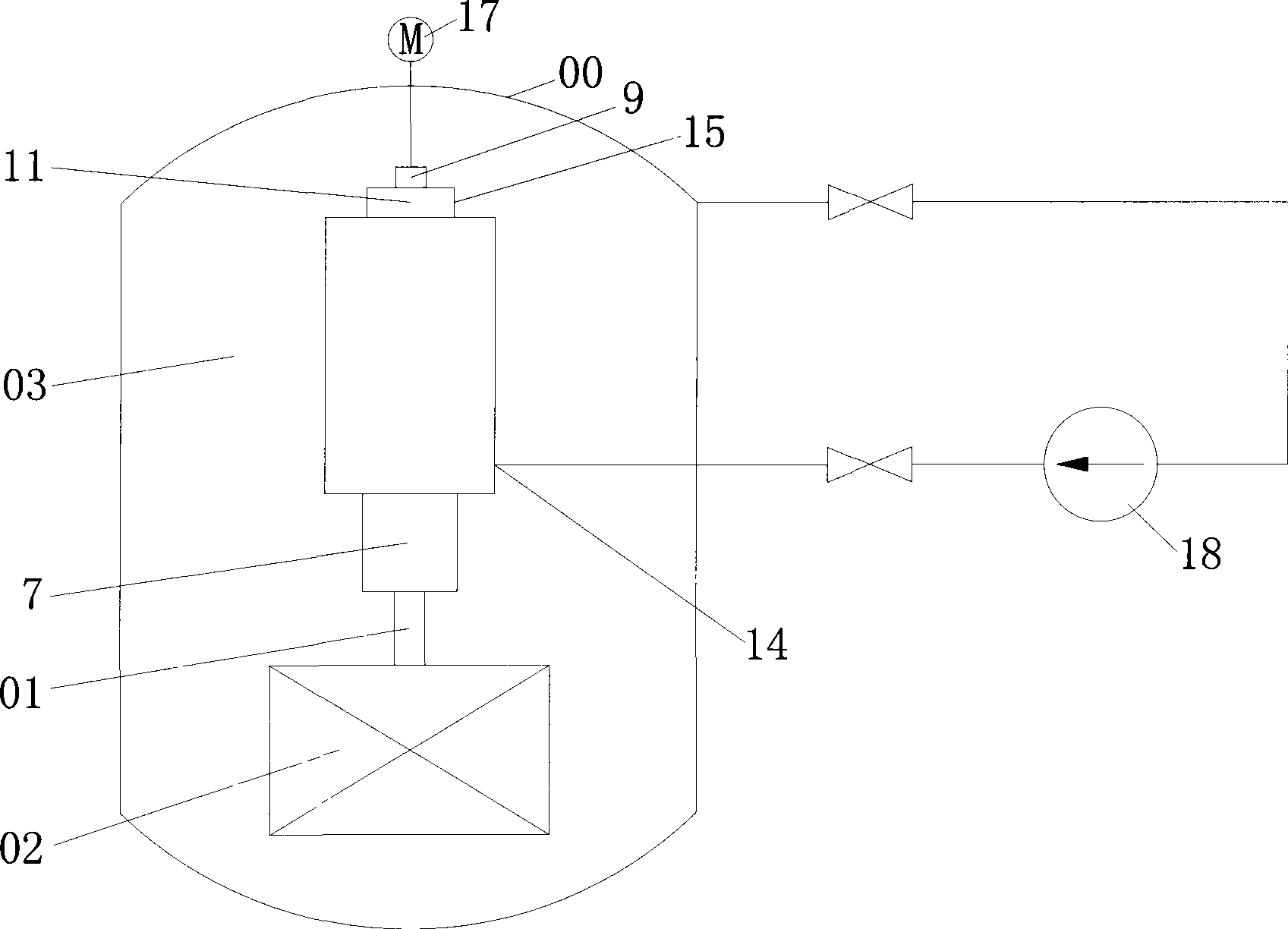

InactiveCN101510452AAchieve continuous motionSimple structureNuclear energy generationNuclear reaction controlNuclear reactorElectric machine

The invention provides a continuously moving-type control rod hydraulic drive device of a nuclear reactor, which comprises a drive cylinder barrel, an internal sleeve, a runner sleeve, a lower end cover, a piston, a hollow piston rod, a servo tube, a leading screw, a shift-stopping assembly and a power source (a motor and a water pump). The control rod hydraulic drive device takes a refrigerant (water) in a pressure container of the nuclear reactor as a working substance, and the refrigerant (water) flows along a flowing channel formed internally therein after being pressurized by a water pump; the motor and the auxiliary moving servo tube of screw transmission are used for changing the width of a changeable choke formed between the end surface of the servo tube and the inner bottom surface of the hollow piston rod so as to change the pressure at two sides of the piston and drag a control rod fixedly connected with the outer end of the hollow piston rod to move. The control rod hydraulic drive device has the advantages that since no electron device required for solenoid drive exists, the requirement on working environment is not high; the continuous movement of the control rod can be realized; the drive device has simple structure and convenient processing and is easy for operation and programmed control; the limitation change range of the pressure and flow of working water is relatively wide, and the drive device has good safety and stability.

Owner:HARBIN ENG UNIV

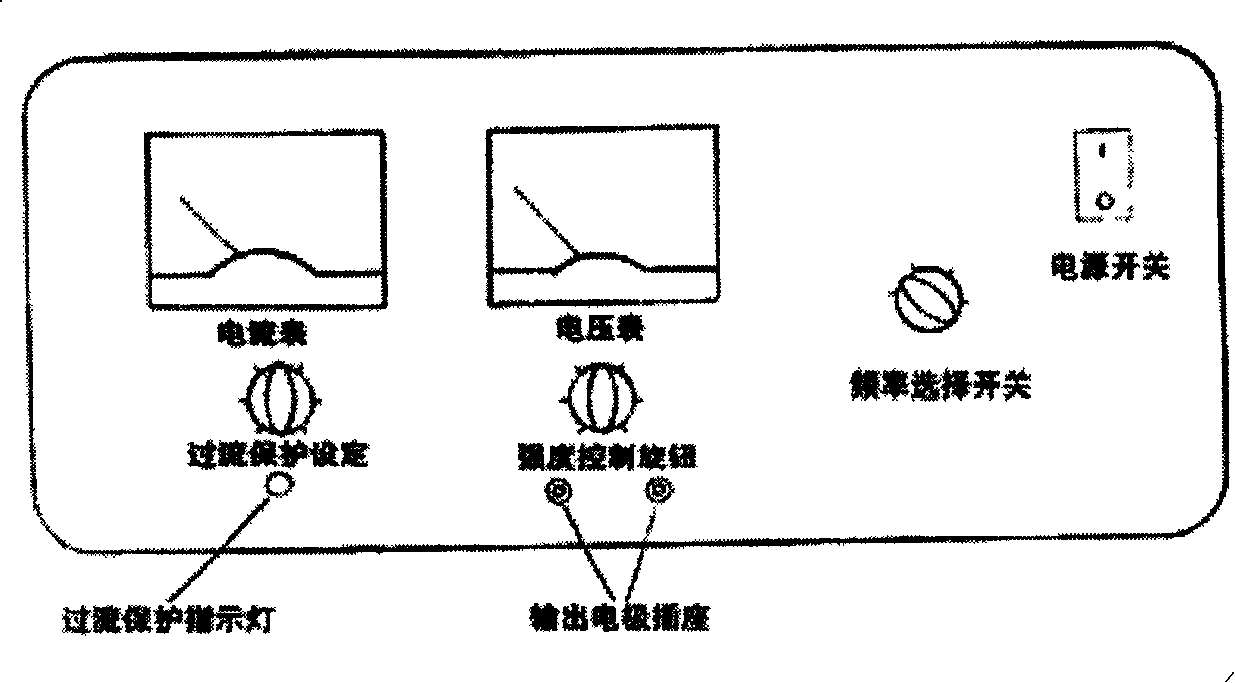

Low frequency resonance biological electric therapeutic instrument

The present invention discloses a low-frequency resonance bio-electric trerapeutic equipment, belonging to the fields of medical apparatus and instrument technology, face beautification and heath-care technology. It includes the following several portions: signal generator, signal frequency selector, gain control circuit, power amplifier, electric current sampling and full-wave rectification filter circuit and chip computer control circuit. Said invention provides the connection mode of all the above-mentioned all the portions, and its working principle and operation method.

Owner:王玉玲

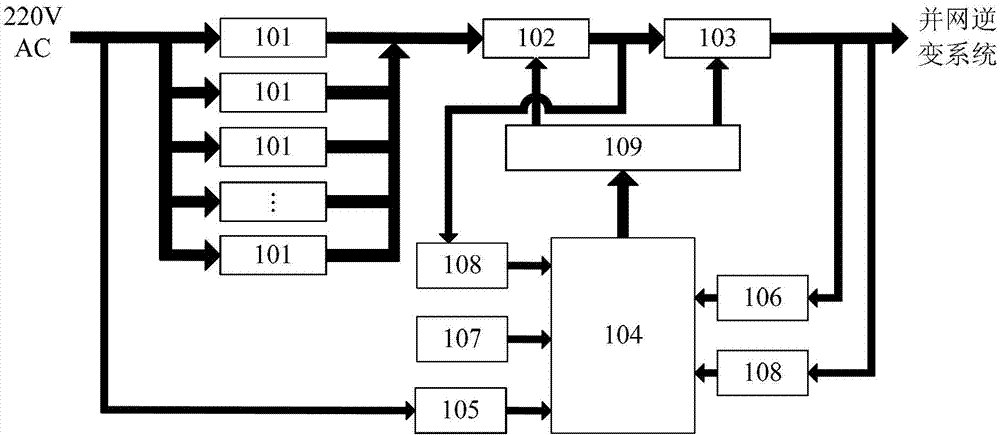

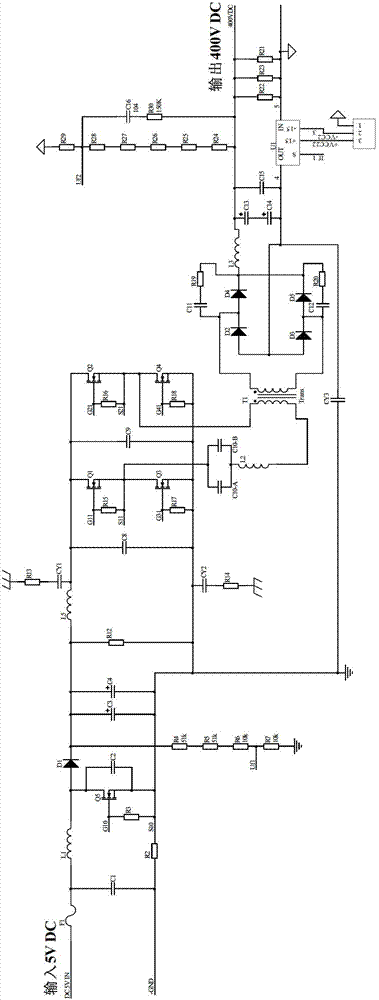

Digitalized-control low-voltage direct-current power source energy feedback type electronic loading boosting system

InactiveCN102832820ARealize full digital controlImprove scalabilityDc-dc conversionSingle network parallel feeding arrangementsLow voltageElectron

The invention discloses a digitalized-control low-voltage direct-current power source energy feedback type electronic loading boosting system comprising a main circuit and a control circuit. The main circuit comprises a Boost module and a DC (direct current)-DC boosting conversion module which are sequentially connected, the Boost module is connected with a parallel low-voltage direct-current power source, and the DC-DC boosting conversion module is connected with a grid-connected inverter system. The control circuit comprises a fault protection circuit module, a current and voltage sampling and signal processing module, a DSP (digital signal processor) embedded type system module and a high-frequency driving module. The digitalized-control low-voltage direct-current power source energy feedback type electronic loading boosting system thoroughly solves the problems that energy feedback is hard to realize during ageing of the low-voltage direct-current power source and a conventional static loading is energy-consuming, heating and large in size, and is energy-saving, efficient, environment-friendly, reliable in performance, high in automation degree and stable in power source ageing quality, and is particularly applicable to reliability test, on-load test and output characteristic test of the low-voltage direct-current power source.

Owner:SOUTH CHINA UNIV OF TECH

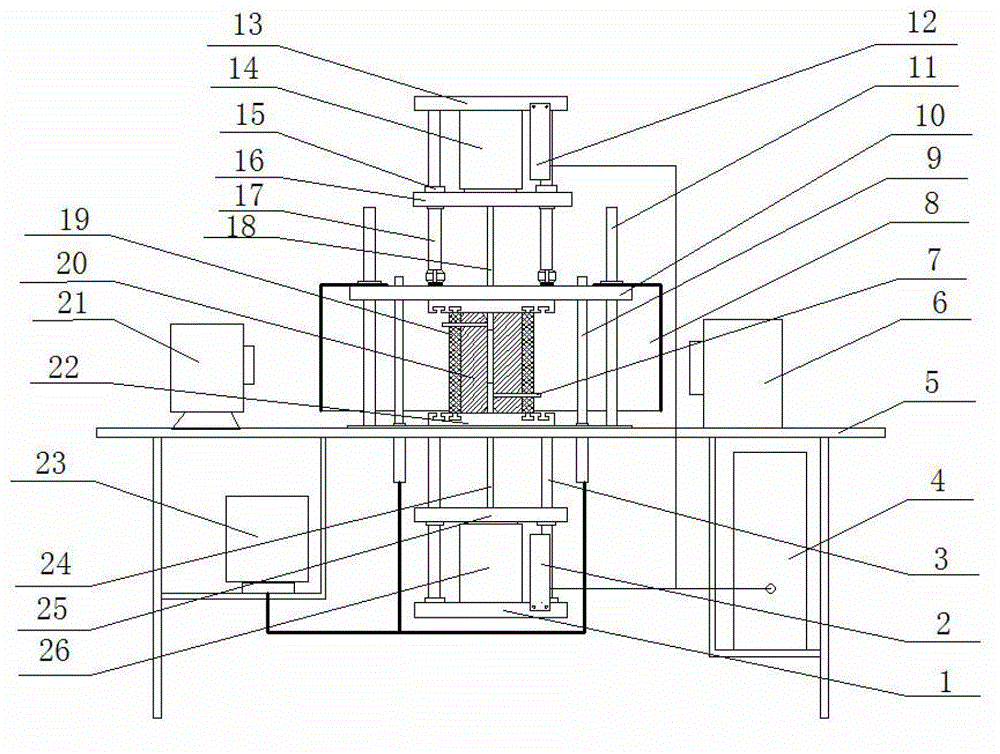

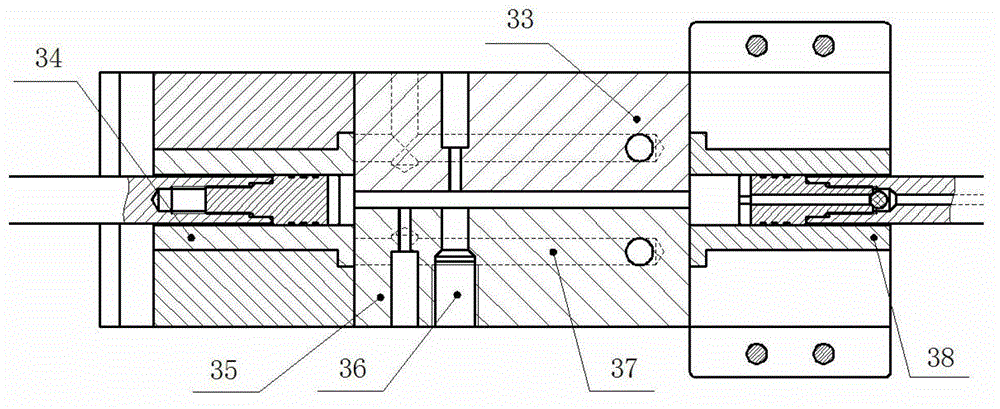

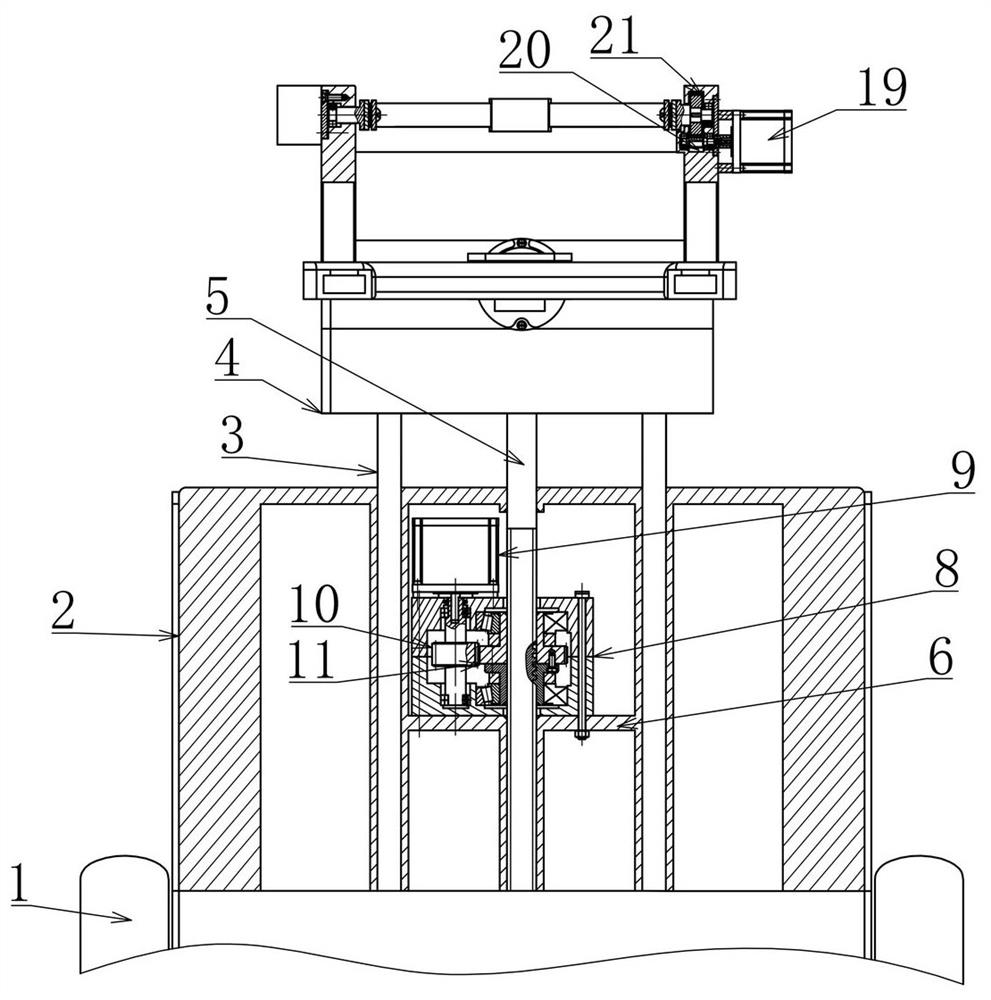

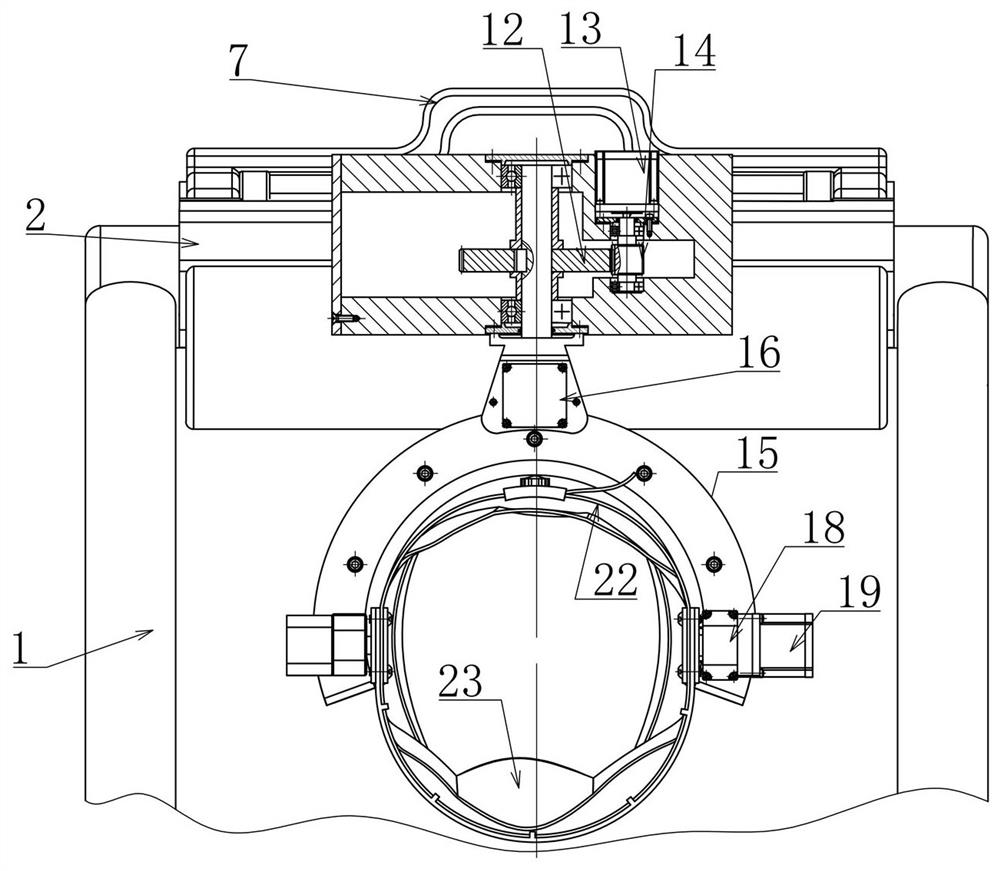

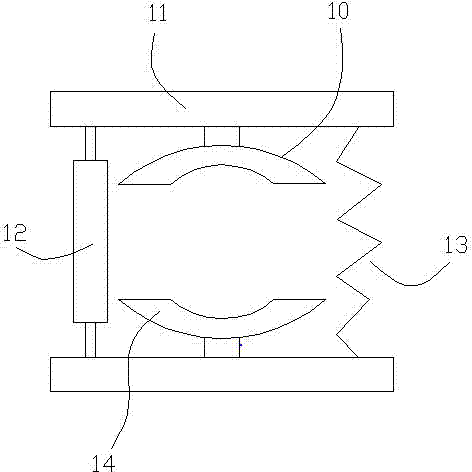

Plastic vibration processing and sample molding integration test equipment and method

The invention discloses plastic vibration processing and sample molding integration test equipment and a method. The equipment comprises a hydraulic power system, a vibration power driving system, a test platform, a piston assembly, a central mould, a visualization device, a controlling system and the like. The equipment and the method combine vibration field quantity with mould sample molding, combine cutting, pressing, vibration and sample processing molding function into a whole, are different from rheological property research limited by polymer of a traditional rheometer, avoid form change of plastic mixture structures when materials in a test cavity are taken out, monitor a microstructure online directly or directly mold and obtain detecting samples. The plastic vibration processing and sample molding integration test equipment and the method can not only achieve the rheological property test of moving state and steady state of the polymer, but also be used for microstructure form research of a plurality of polymer systems under multi-element field quantity and influence rule research between processing performance and technological conditions. The plastic vibration processing and sample molding integration test equipment and the method can be widely applied to industries of material, chemistry, pharmacy, coating, food, building and the like.

Owner:ZHEJIANG UNIV +1

Heavy-denier-yarn spinning technology of semi-continuous and high-speed spinning machine

ActiveCN103409821AReduce in quantityLow manufacturing costWet spinning methodsYarnManufacturing engineering

The invention relates to a heavy-denier-yarn spinning technology of a semi-continuous and high-speed spinning machine, and belongs to the technical field of spinning of the semi-continuous and high-speed spinning machine. The technology comprises the steps of glue supplying, thread-line forming, spinning and winding. The spinning is finished through the spinning device, the spinning device comprises three spinning rollers which are transversely arranged relative to an operation face of a spinning surface, the three spinning rollers are respectively a drafting roller, a solidifying roller and a disacidifying roller, thread-lines sequentially surround the drafting roller, the solidifying roller and the disacidifying roller, and the drafting, the solidifying and the disacidifying in the spinning steps are finished under the rotation of the spinning rollers. The heavy-denier-yarn spinning technology of the semi-continuous and high-speed spinning machine solves the problems that due to the fact that response of thread-lines of a semi-continuous spinning machine in the prior art is insufficient, the spinning speed can not be accelerated, and the production efficiency and the product quality can not be improved at the same time; by changing the arrangement direction of the spinning rollers, the thread-lines can walk a longer distance while the spinning speed of the spinning machine is accelerated and structures of other parts of original equipment are not changed, the thread-lines and acid bath react more fully, and the production efficiency and the product efficiency can be improved at the same time.

Owner:YIBIN HIEST FIBER +2

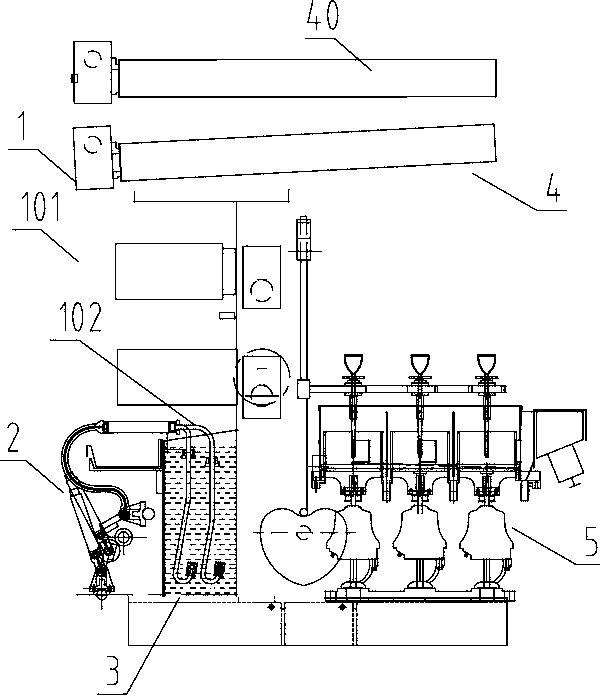

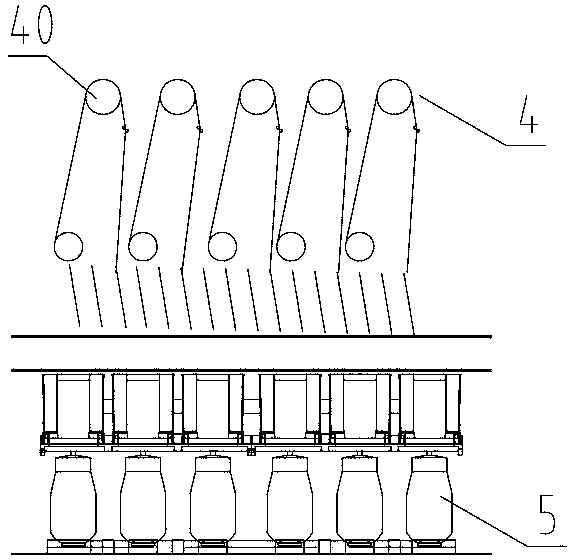

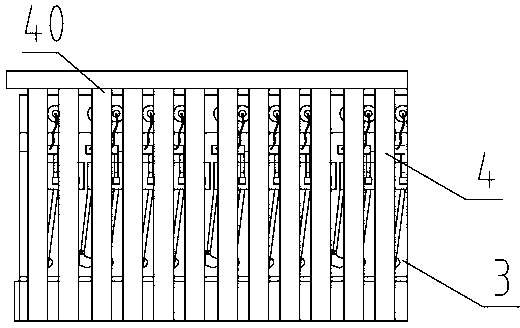

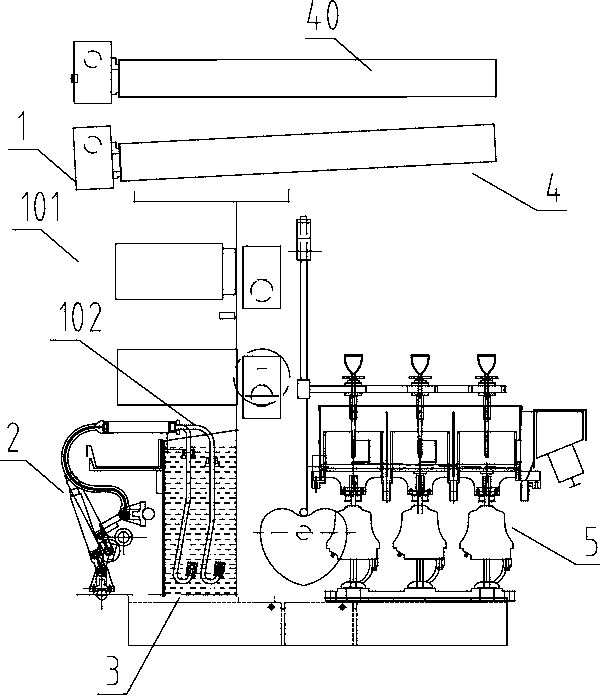

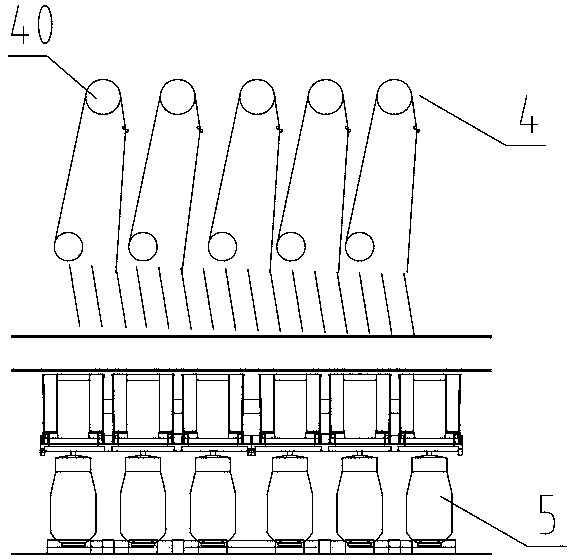

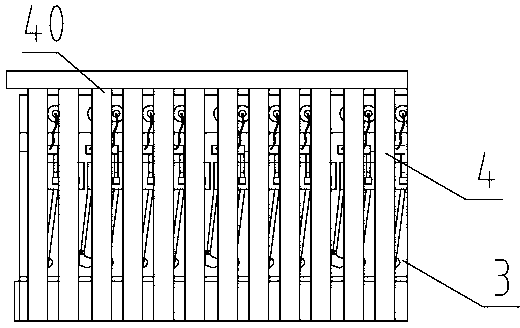

Novel semi-continuous high-speed spinning machine

ActiveCN103409825AEasy to operateControllableArtificial thread manufacturing machinesWet spinning methodsEngineeringSpin speed

The invention relates to a novel semi-continuous high-speed spinning machine which comprises a rack, a glue supply device, a filament strip forming device, a spinning device and a winding device. The spinning device comprises a spinning roller which is transversely arranged relative to the operating surface of a spinning face, and the two ends of the spinning roller are fixed on the rack. The novel semi-continuous high-speed spinning machine improves spinning speed, ensures that filament strips are sufficiently reacted, and then achieves the purposes of ensuring the quality of the filament strips, improving production efficiency and reducing spinning cost.

Owner:YIBIN HIEST FIBER +2

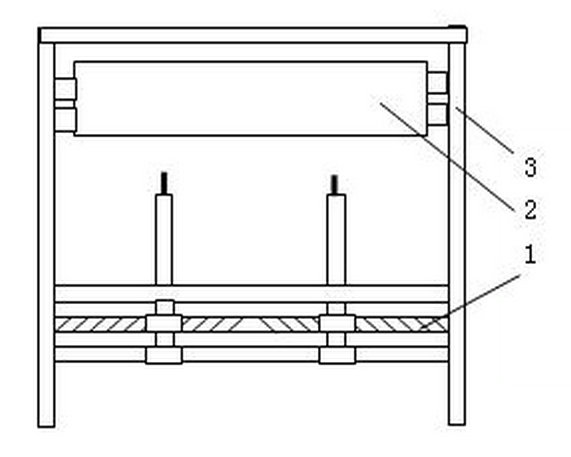

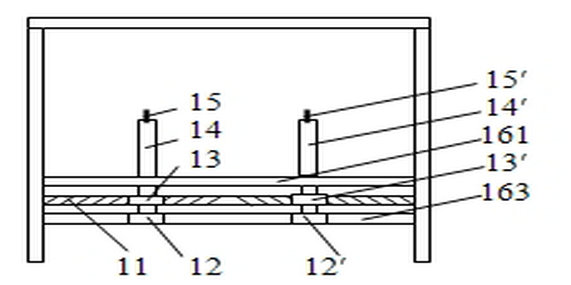

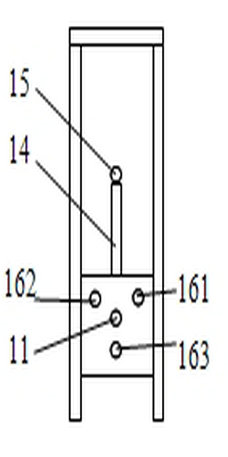

Drawing and heat-setting device

The invention discloses a drawing and heat-setting device, which is used for producing hollow fiber membranes and comprises a frame, a drawing system, a heating system and a transmission control system, wherein the drawing system, the heating system and the transmission control system are installed on the frame. The drawing and heat-setting device is characterized in that the heating system is positioned above the drawing system; the drawing system comprises a left-hand threaded and right-hand threaded screw, three polished rods and two drawing mechanisms in bilateral symmetry; the three polished rods are distributed in an inverted triangular form, and the left-hand threaded and right-hand threaded screw is disposed at the center of the inverted triangle and connected with the transmission control system; the heating system mainly comprises a heating tank and left and right screw lifting mechanisms connected with the same; the transmission control system controls screws of the lifting mechanisms to rotate in the same direction and drives the heating tank to move up and down or pause regularly; an inverted groove is reserved in the middle of the heating tank, and an infrared heating plate is mounted at the inner top of the groove; and the depth and the width of the groove are designed to fit with the length and the diameter of a drawing guide bar, and the length of the groove fits with a largest drawing distance of the drawing guide bar.

Owner:TIANJIN POLYTECHNIC UNIV

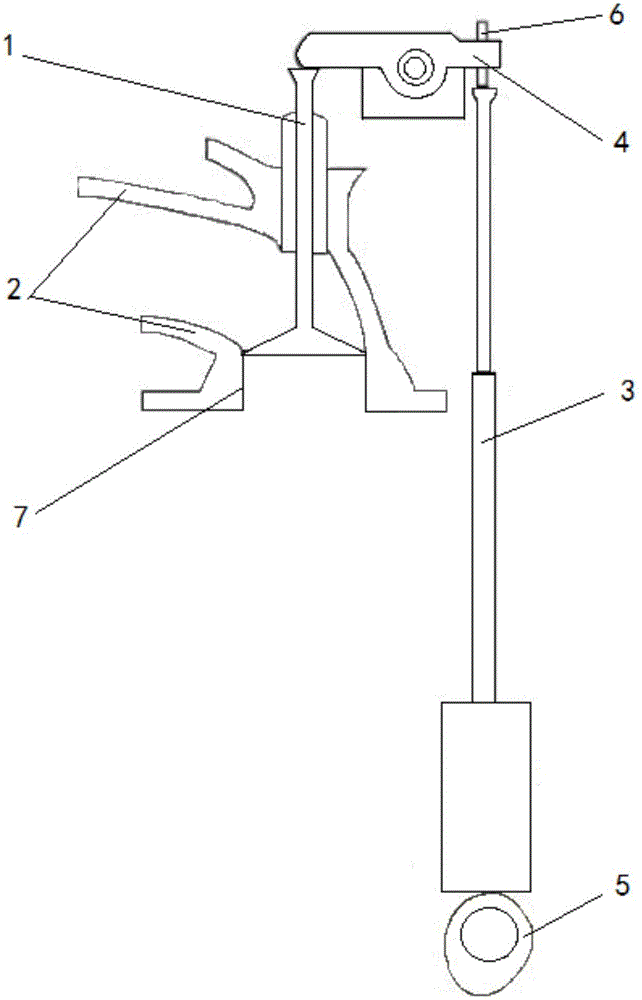

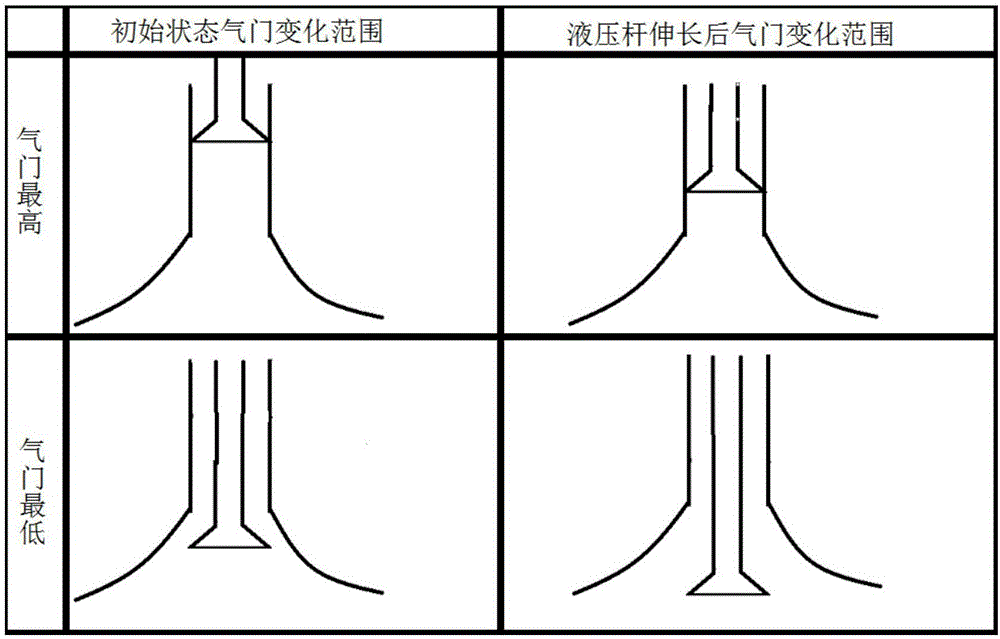

Variable valve timing mechanism

InactiveCN106368755AImprove performanceImprove powerValve arrangementsMachines/enginesVariable valve timingEngineering

The invention relates to a variable valve timing mechanism. The variable valve timing mechanism comprises a valve and a valve transmission assembly. The valve transmission assembly comprises a camshaft, a push rod and a rocker arm. The middle portion of the rocker arm is hinged to a cylinder cover, the left end of the rocker arm abuts against the top of the valve, and the right end of the rocker arm abuts against the top of the push rod. The lower end of the push rod abuts against a cam of the cam shaft. The push rod is an automatic telescopic push rod. During operation, the camshaft rotates, the cam drives the push rod to move up and down, the left end of the rocker arm pushes the valve downwards to make the valve move downwards to open an air channel when the push rod pushes the rocker arm upwards to make the rocker arm swing anticlockwise, and the valve moves upwards along with uplifting of the left end of the rocker arm to close the air channel when the push rod falls to drive the rocker arm to swing clockwise; and when the push rod moves up and down, the upward stroke of the upper end of the push rod is changed by changing the expansion and contraction quantity of the push rod, and accordingly the valve opening and closing positions and the stroke are changed. According to the variable valve timing mechanism, valve lift can be adjusted and controlled in a stepless mode, the timing phase is made optimal all the time, and the performance of an engine is remarkably improved.

Owner:ZHEJIANG UNIV

Spinning process of three-spinning-roller semicontinuous high-speed spinning machine

InactiveCN103409823AReduce in quantityReduce manufacturing costArtificial thread manufacturing machinesArtificial filament washing/dryingPolymer scienceSpinning

The invention relates to a spinning process of a three-spinning-roller semicontinuous high-speed spinning machine, and belongs to the technical field of spinning of semicontinuous spinning machines. The spinning process comprises the steps of glue supplying, silk strip forming, spinning and winding. The spinning is completed through a spinning device, the spinning device comprises three spinning rollers transversely arranged relative to an operating surface of a spinning face, silk strips surround the spinning rollers, and drafting, solidification and deacidification in spinning steps are completed under rotation of the spinning rollers. The spinning process solves the problem that due to the fact that the silk strips of a semicontinuous spinning machine in the prior art reacts insufficiently, the spinning speed cannot be improved, and consideration cannot be given to production efficiency and product quality at the same time; the distribution direction of the spinning rollers is changed, so the spinning speed of the spinning machine is improved, structures of other parts of original equipment are not changed, meanwhile the silk strips can be moved for longer distances and react with acid bath more sufficiently, and the consideration is given to the production efficiency and the product quality at the same time.

Owner:YIBIN HIEST FIBER +2

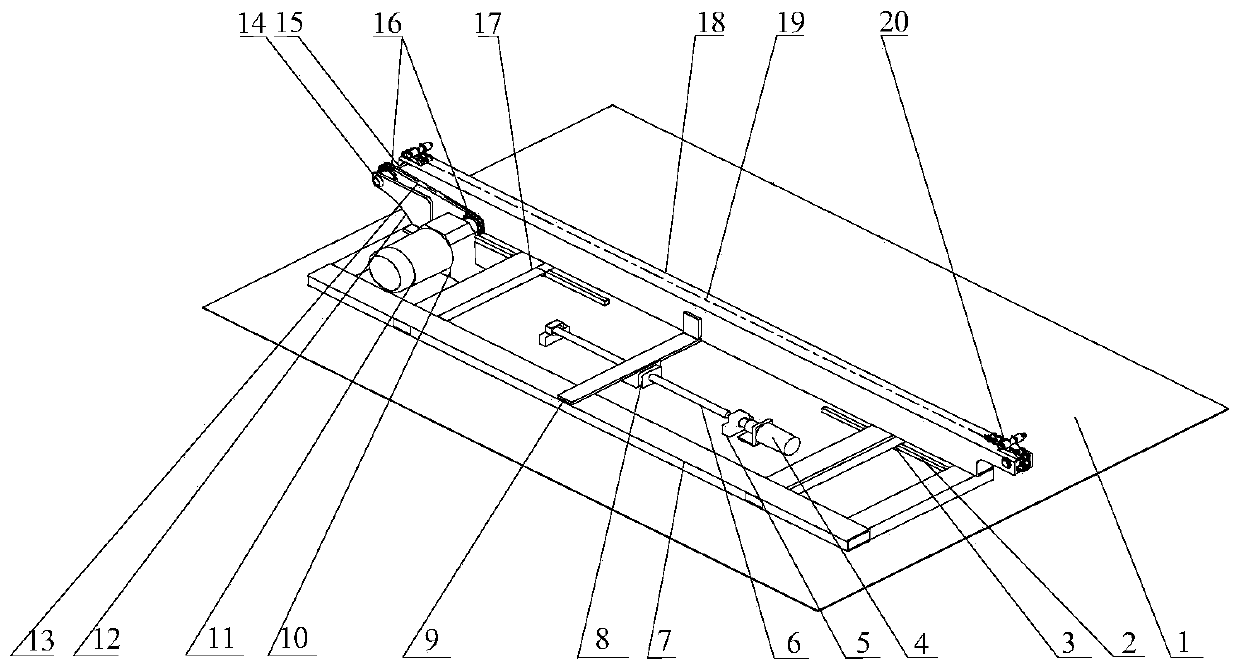

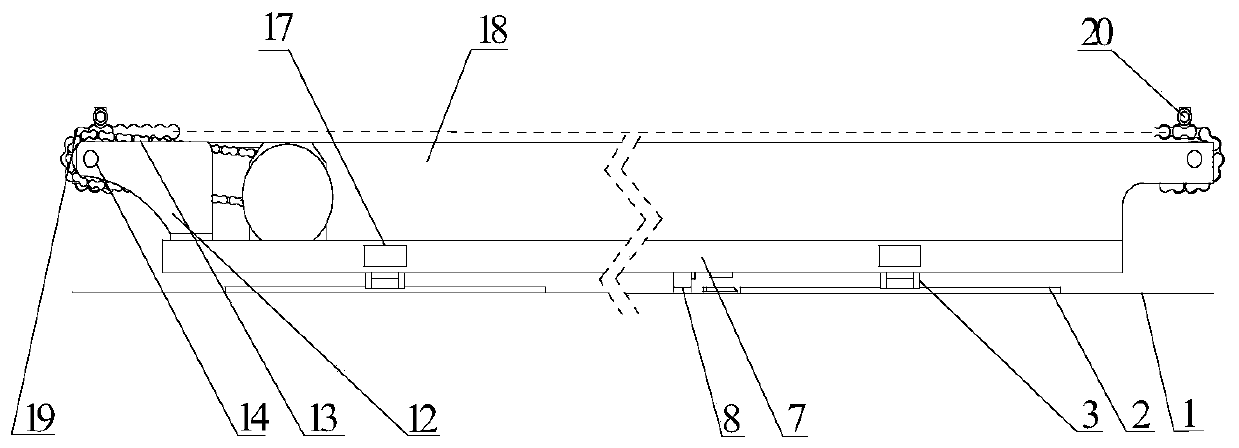

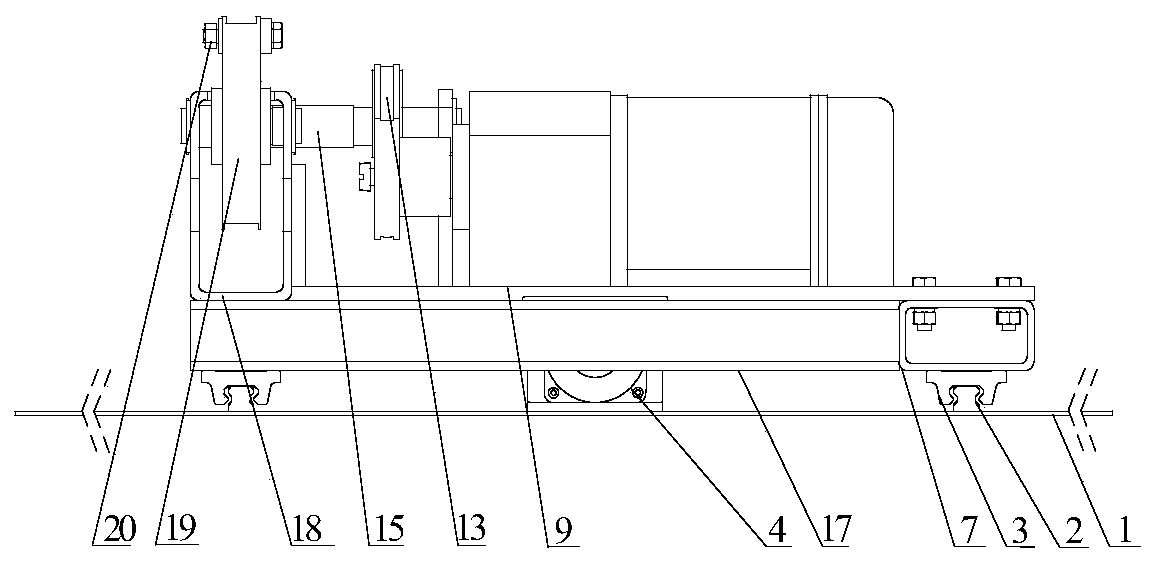

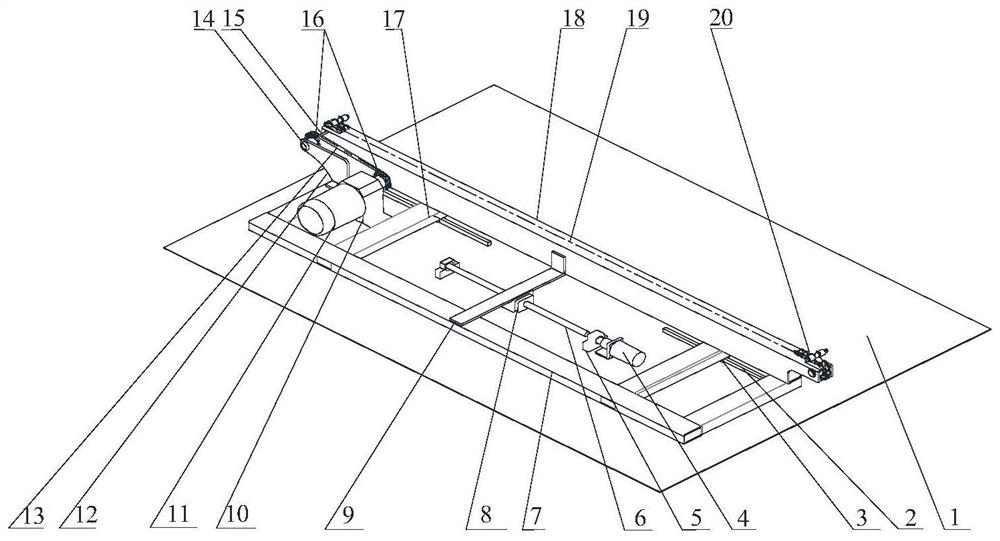

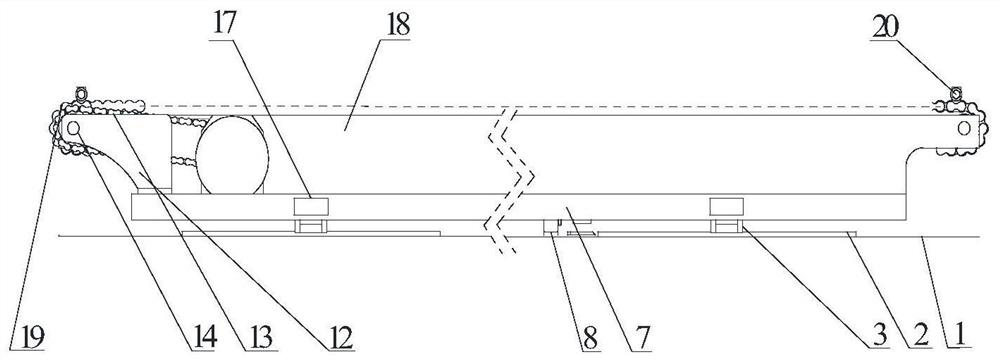

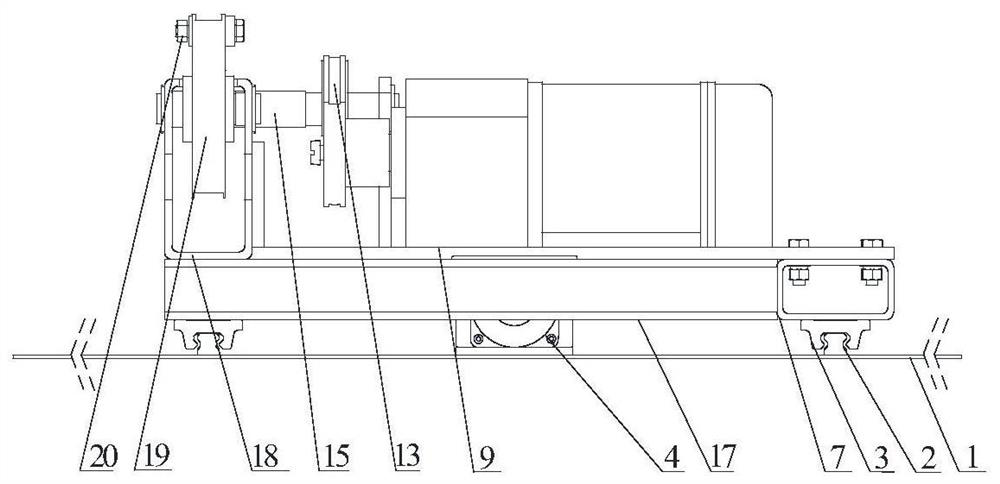

Push-pull pallet automatic storing and taking device

The invention provides a push-pull pallet automatic storing and taking device. The storing and taking device is characterized in that two sets of guide rails are fixed on the upper surface of a stacking machine platform; a longitudinal beam in a supporting frame is located on one side of the stacking machine platform, a main beam is located on the other side of the stacking machine platform; supporting shafts are arranged at the two ends of the inner cavity of the main beam respectively; driven chains are arranged on the supporting shafts at the two ends of the inner cavity of the main beam ina sleeved mode, so that the driven chains penetrate through the supporting shafts at the two ends and penetrate through the inner cavity of the main beam to form an operation loop; two drag hook components are connected to the driven chains in a chain mode; one end of a nut seat connecting plate is fixed on the inner side surface of the main beam, and the other end of the nut seat connecting plate is fixed on the upper surface of the longitudinal beam. The device has the advantages that the structure is simple and compact, the operation is light and efficient, and the storing and taking tasksof the pallets of various sizes can be completed by changing the position of the drag hooks

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

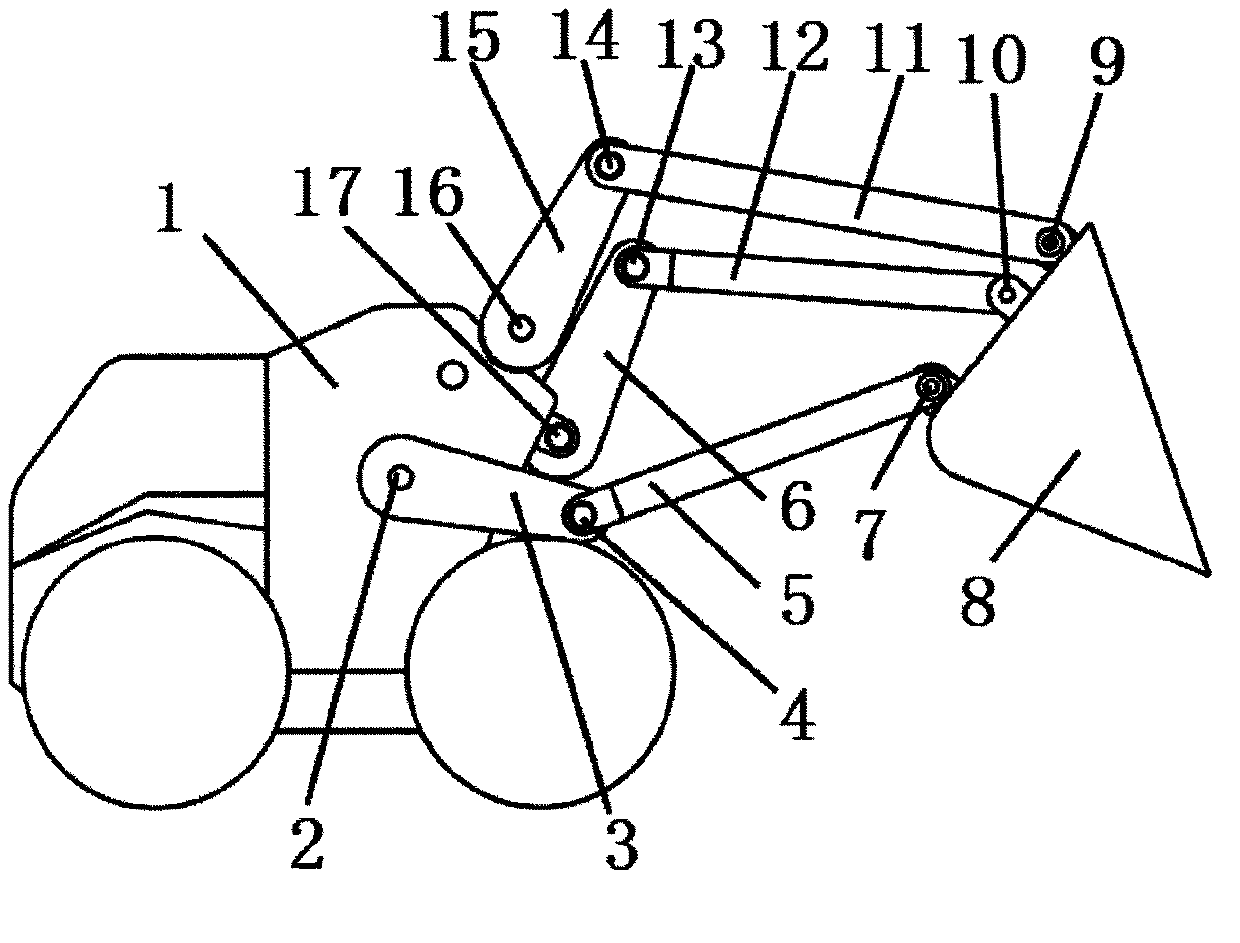

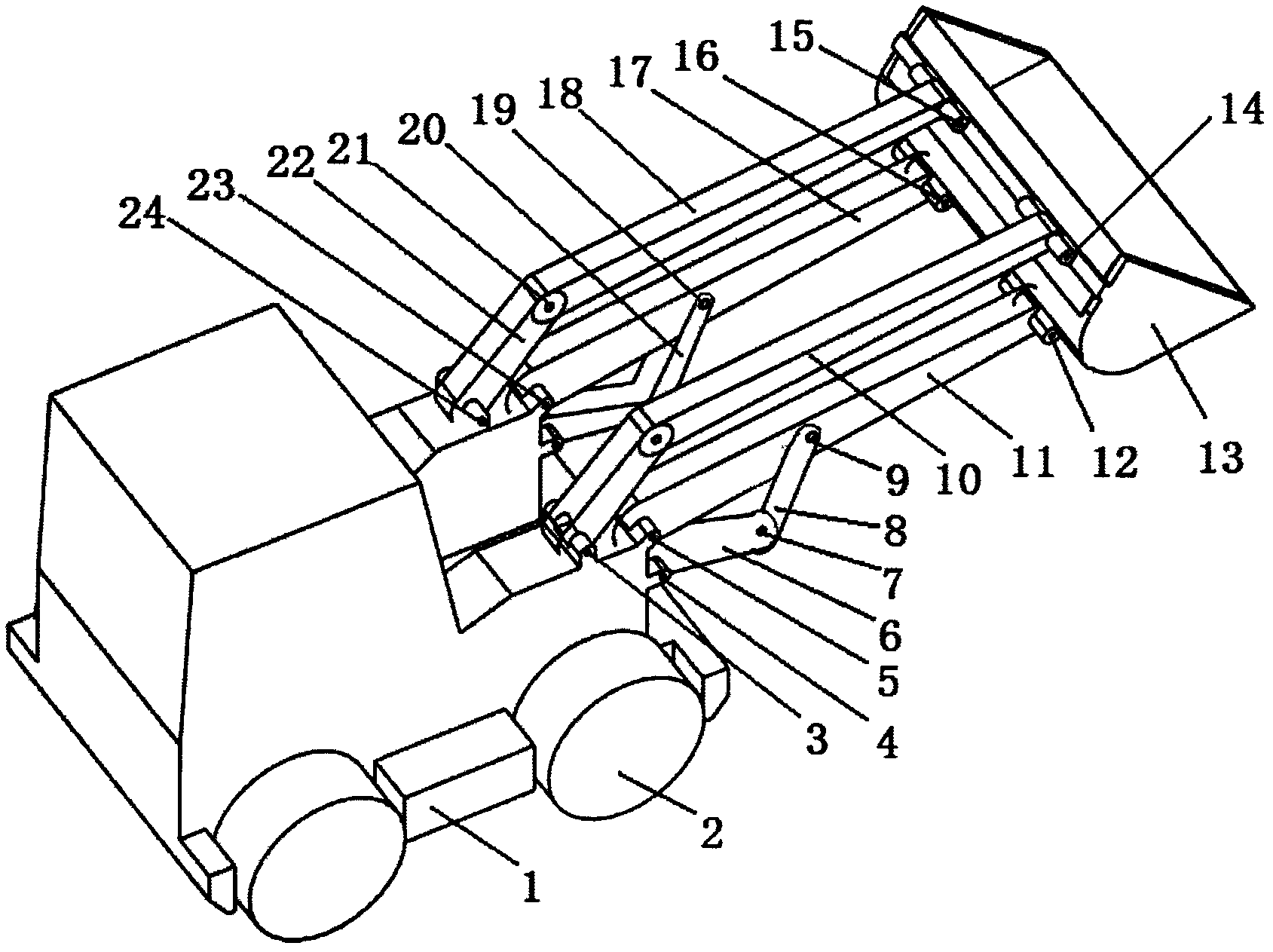

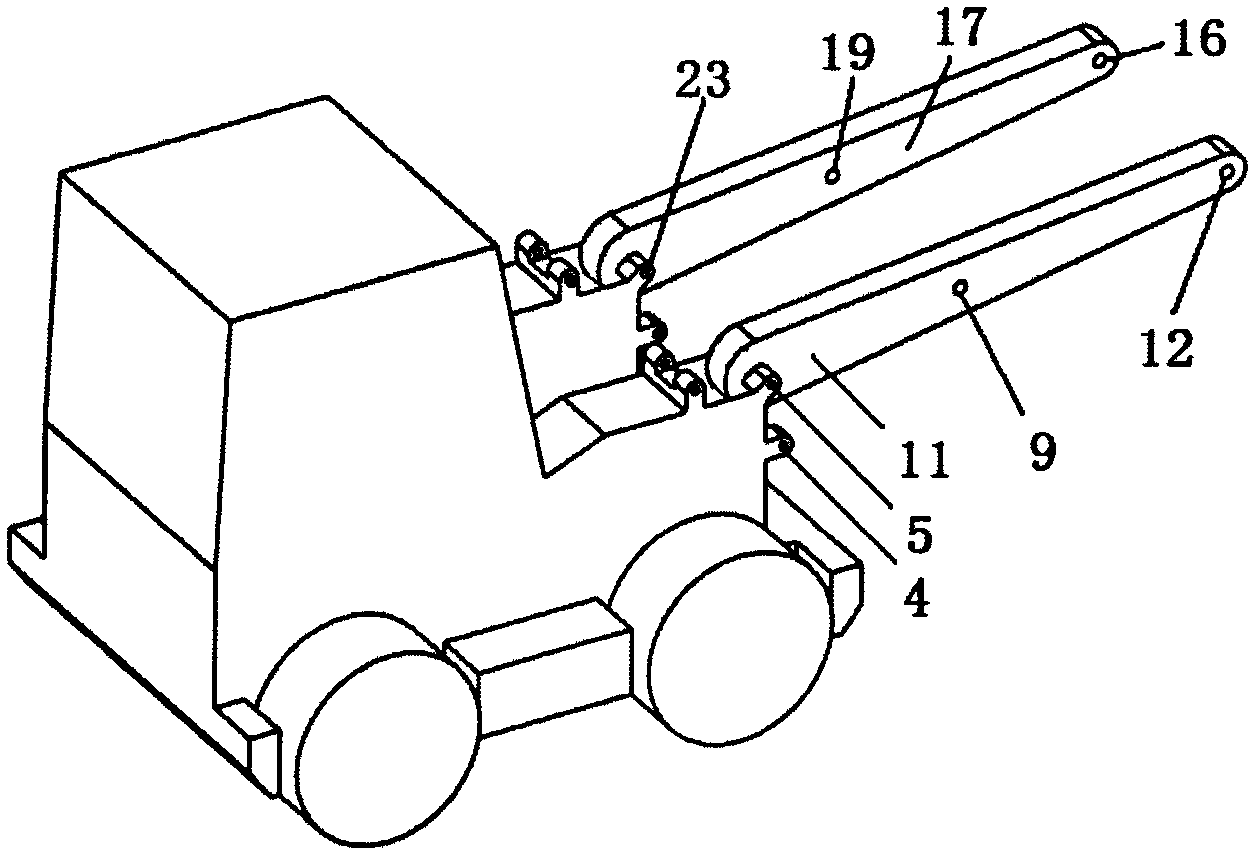

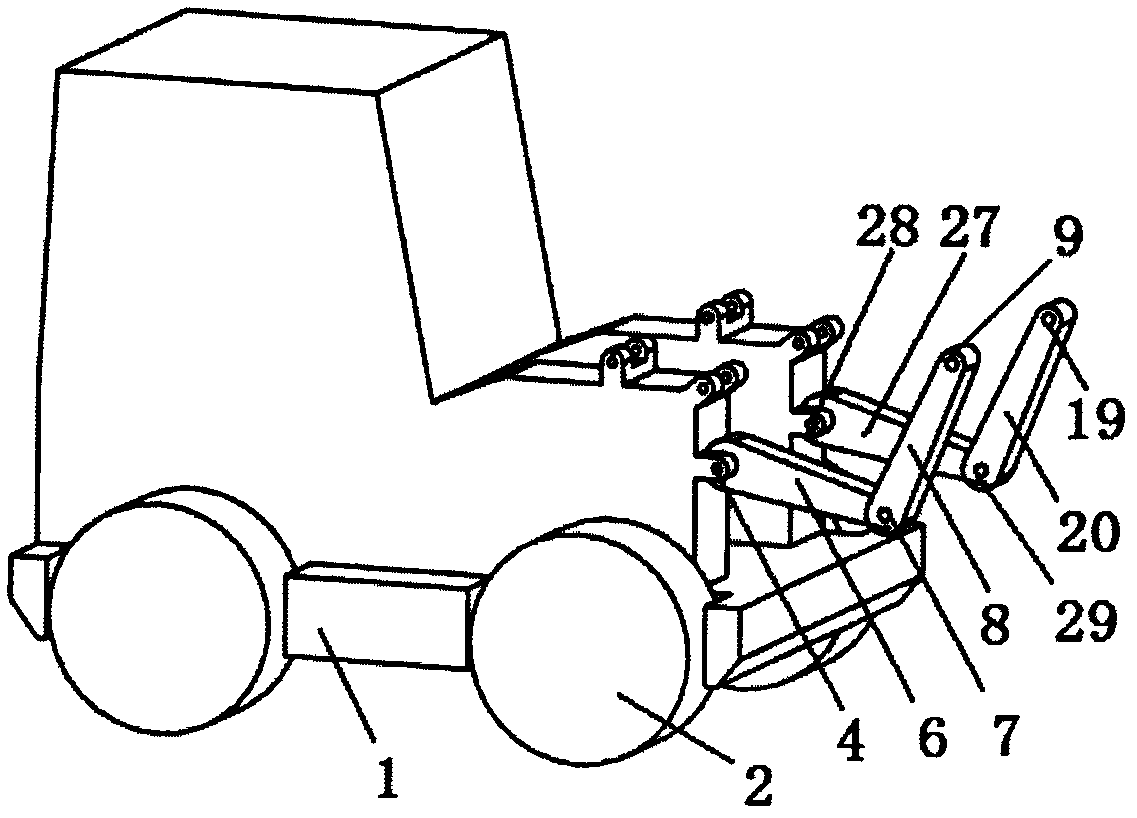

Miniature multi-freedom-degree controllable mechanical type crowd shovel excavating loading mechanism

InactiveCN102995674AReduce usageReduce weightMechanical machines/dredgersNumerical controlEngineering

A miniature multi-freedom-degree controllable mechanical type crowd shovel excavating loading mechanism comprises a machine frame, a first branch chain, a second branch chain, a third branch chain and a bucket. The first branch chain, the second branch chain and the third branch chain are driven by a servo motor installed on the machine frame, and actions of excavating, shoveling, discharging and the like are achieved through mutual matching of the first branch chain, the second branch chain and the third branch chain to jointly finish the excavating loading operations. The excavating loading mechanism has the working space and flexibility of a traditional loader, meets the loading requirements, further can perform excavating operation, meets certain excavating requirements and avoids the shortcomings of high manufacture cost, complex maintenance and the like of a hydraulic element of the hydraulic loader. By adopting the servo motor for driving, automation and numerical control can be achieved easily, and compared with other excavating loading mechanisms, the miniature multi-freedom-degree controllable mechanical type crowd shovel excavating loading mechanism is simple in structure, low in manufacture cost, easy to maintain and particularly suitable for manufacturing miniature excavating loading all-in-one machines.

Owner:GUANGXI UNIV

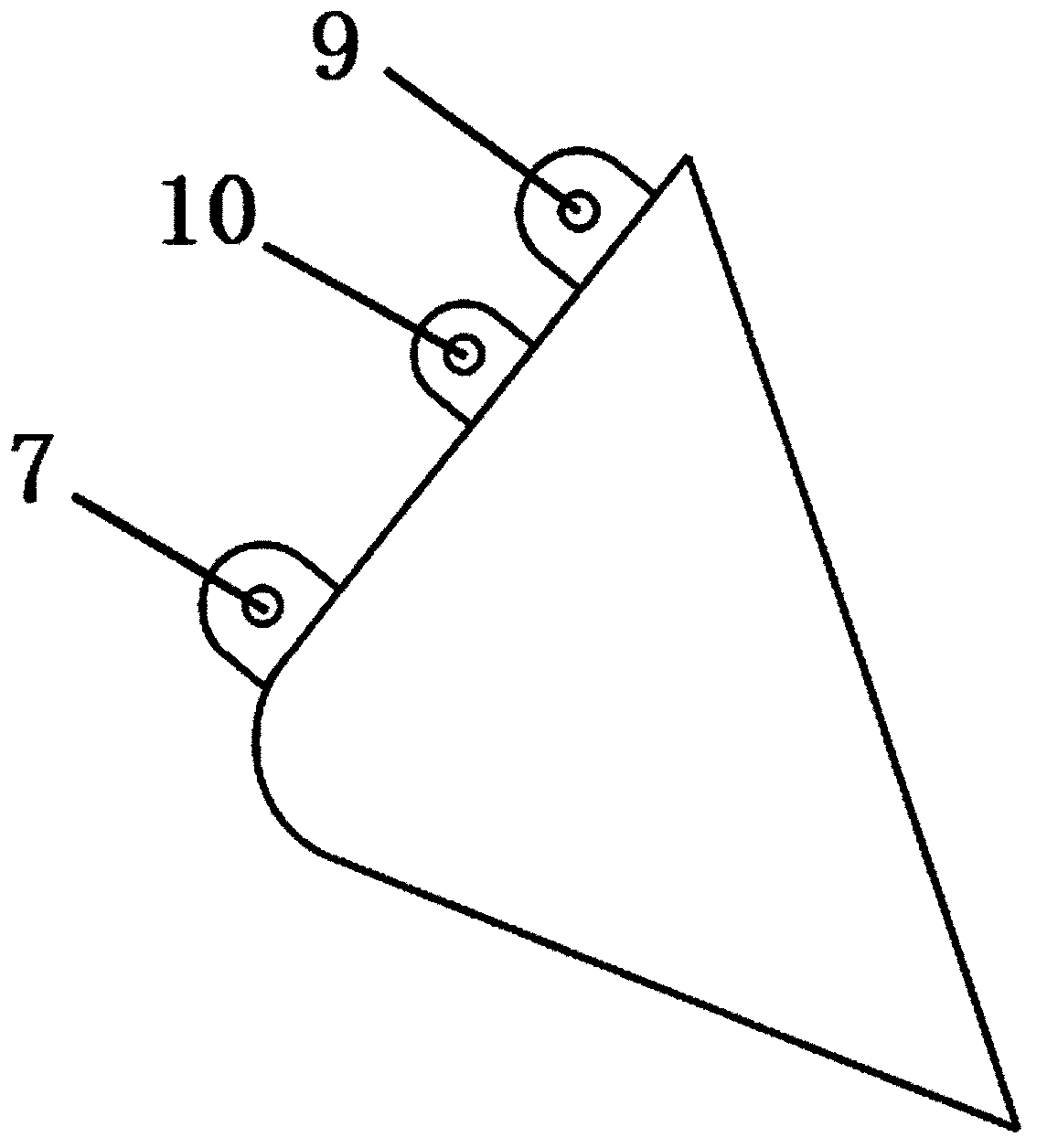

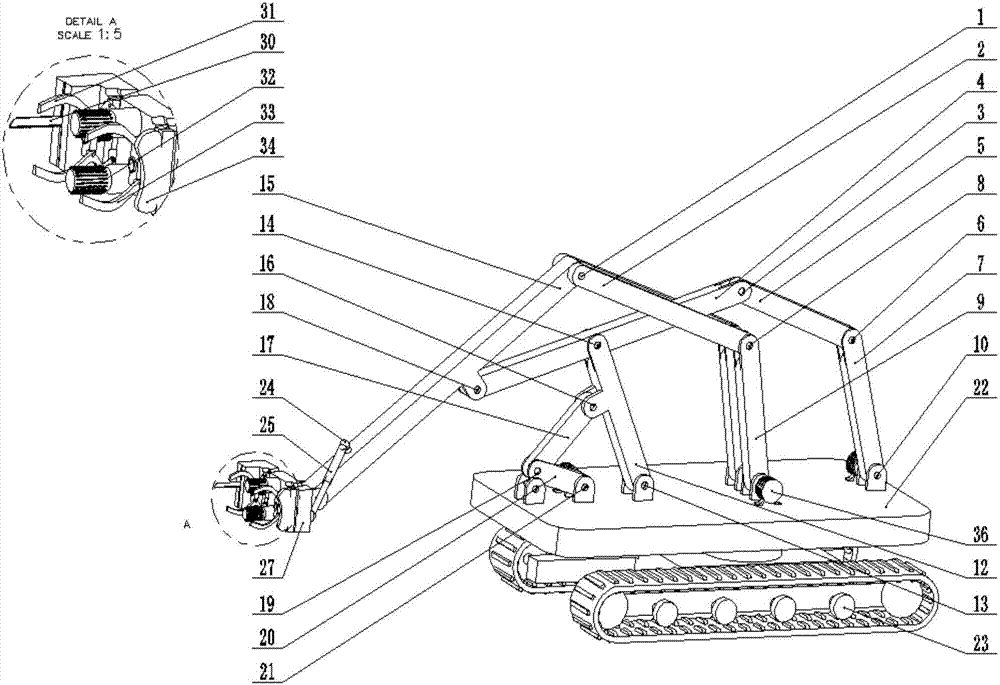

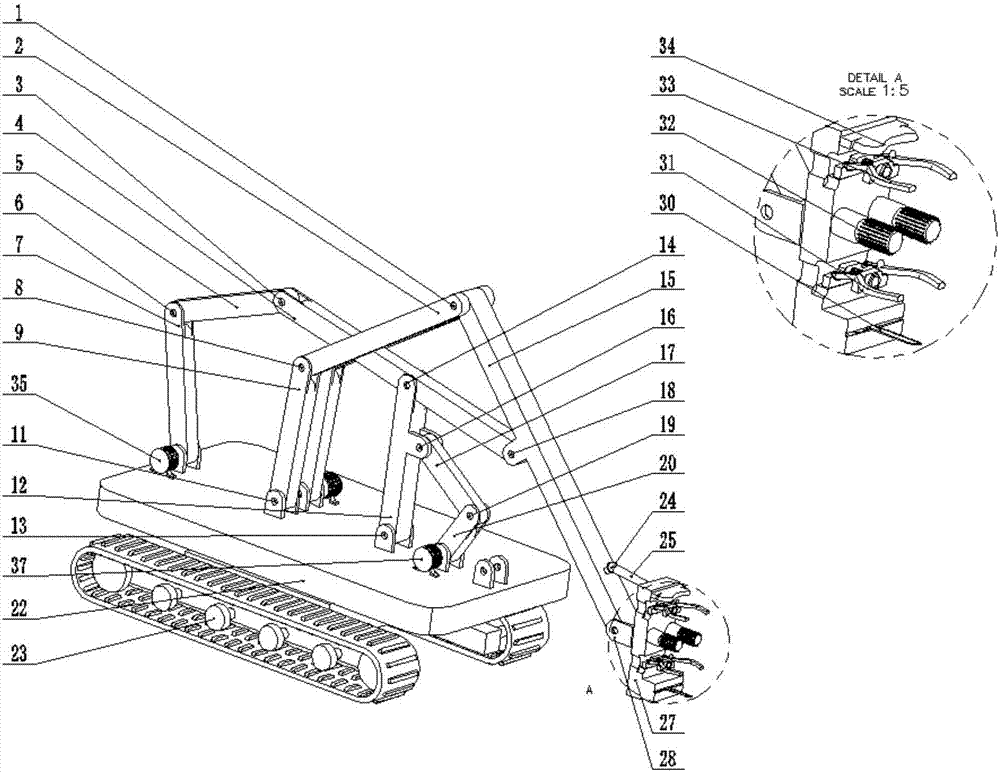

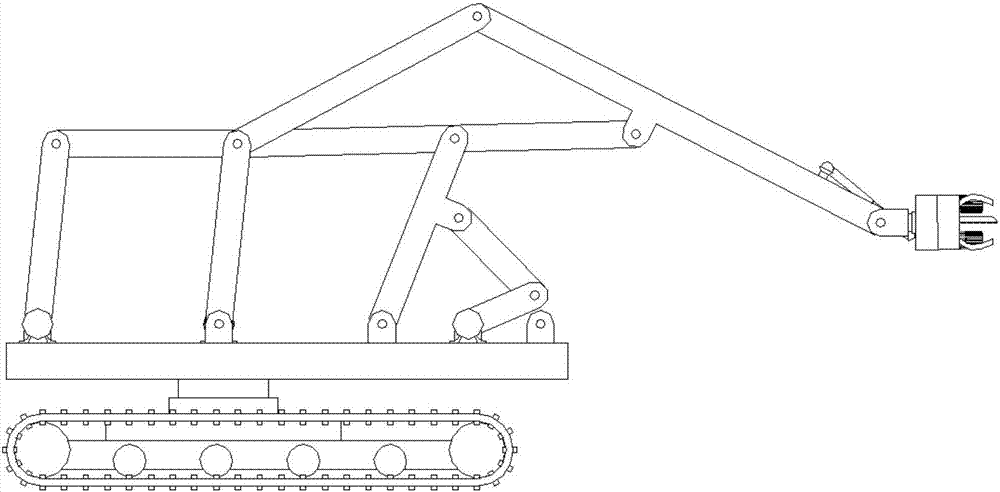

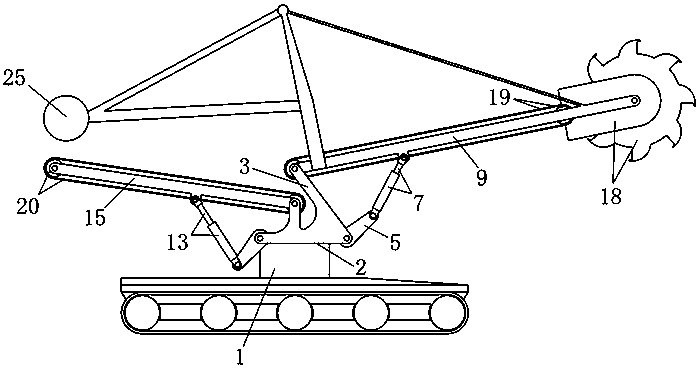

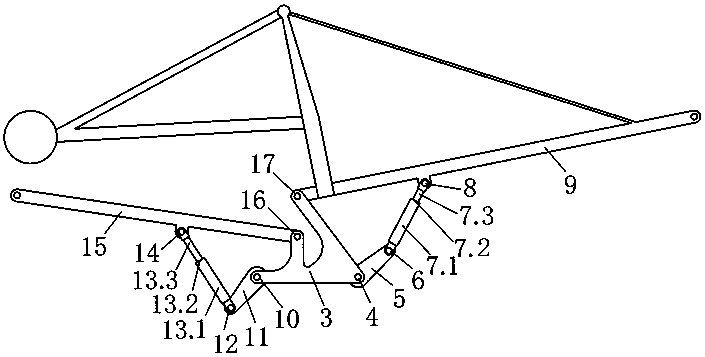

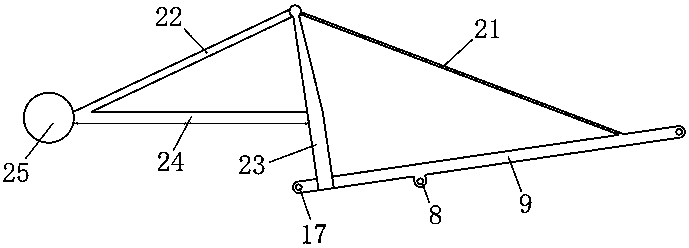

Servo-driven large-space dual-configuration metamorphic-type pruning and cutting robot for trees

A servo-driven large-space dual-configuration metamorphic pruning and cutting robot for trees comprises servo motors, pruning and cutting saw assembly, a crawler-type walking device, a rack, a driving arm, a transmission arm, a working arm, a hinge, a hydraulic cylinder and a hooke joint, wherein the driving arm comprises three connecting rods, and the transmission arm comprises five connecting rods; the working arm is used as an output component and connected with the pruning and cutting saw assembly, and the pruning and cutting saw assembly comprises a knife and saw mechanism, a lower clamping mechanism, a roller, an upper clamping mechanism and a pruning knife. Because the driving arm is subjected to programmable servo controls by the three servo motors, combining with dual configurations of the robot capable of achieving flexible metamorphism, the robot can flexibly complete tasks of pruning, cutting or sectional cutting out within large space. The robot has the prominent advantages of being controllable through the programmable servo controls, big in working space, high and dynamic in stability and low in manufacturing cost.

Owner:GUANGXI UNIV

Three-degree-of-freedom electrohydraulic-mechanism numerically-controlled bucket wheel machine

InactiveCN109677944ARealize three-degree-of-freedom flexible and controllable motionLarge working spaceLoading/unloadingHigh energyThree degrees of freedom

The invention discloses a three-degree-of-freedom electrohydraulic-mechanism numerically-controlled bucket wheel machine. The three-degree-of-freedom electrohydraulic-mechanism numerically-controlledbucket wheel machine comprises a travelling mechanism, a rack, a front cantilever lifting mechanism, a bucket wheel mechanism and a conveying system. The front cantilever lifting mechanism is a full-revolute-pair planar two-degree-of-freedom mechanism; under computer programming control, a drive rod drives a front cantilever to carry out pitching movement through the transmission of a connection rod, and then completes two-degree-of-freedom excavation working; the connection rod is a telescopic rod, composed of a cylinder body and a piston rod, and fully filled with a liquid; and the tipping load of the front cantilever can be effectively overcome and the problem of overload protection can be solved in actual engineering application. The numerically-controlled bucket wheel machine avoids the problems of high energy consumption, high maintenance cost and the like of a hydraulic bucket wheel machine, avoids the defects of low flexibility, small working space and the like of a pure mechanical bucket wheel machine, has the characteristics of being low in energy consumption, low in maintenance cost, high in reliability and the like, is larger in working space and higher in flexibility compared with a single-degree-of-freedom front cantilever lifting mechanism, and is powerful equipment for modernized industrial continuous loading and unloading for bulk materials.

Owner:SHANDONG JIAOTONG UNIV

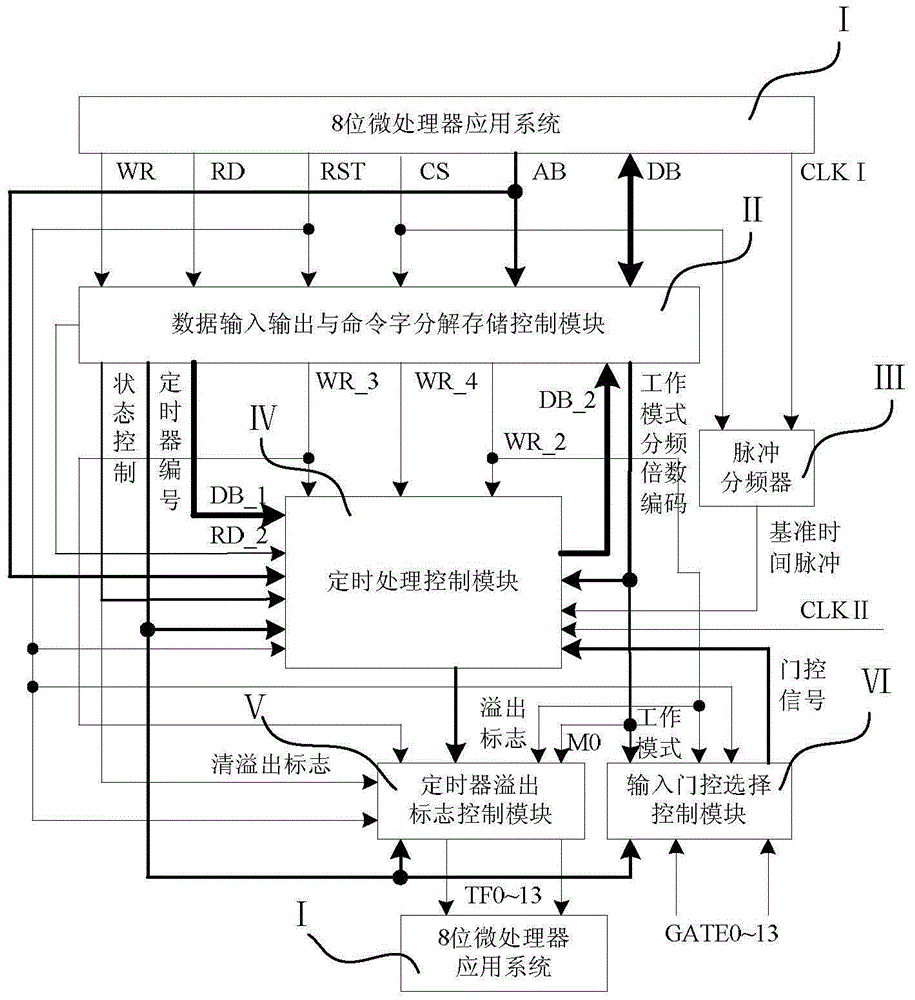

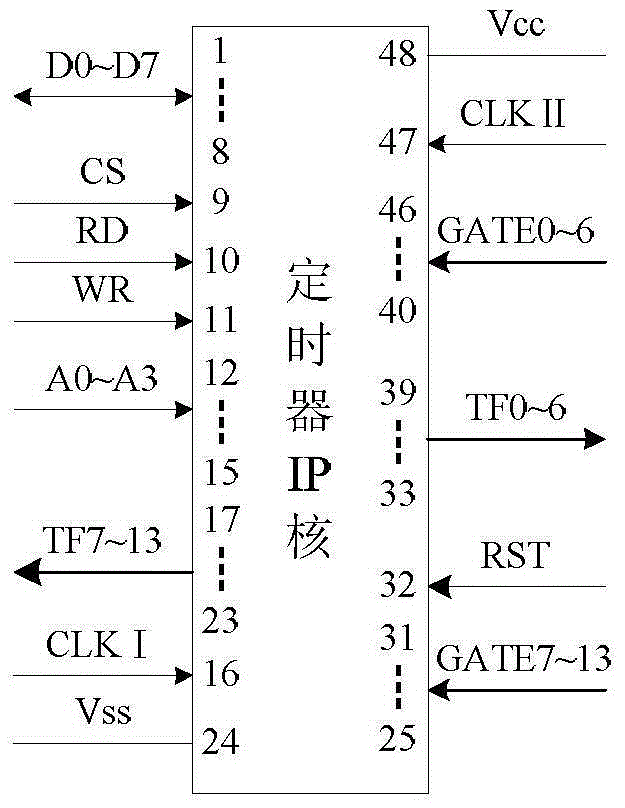

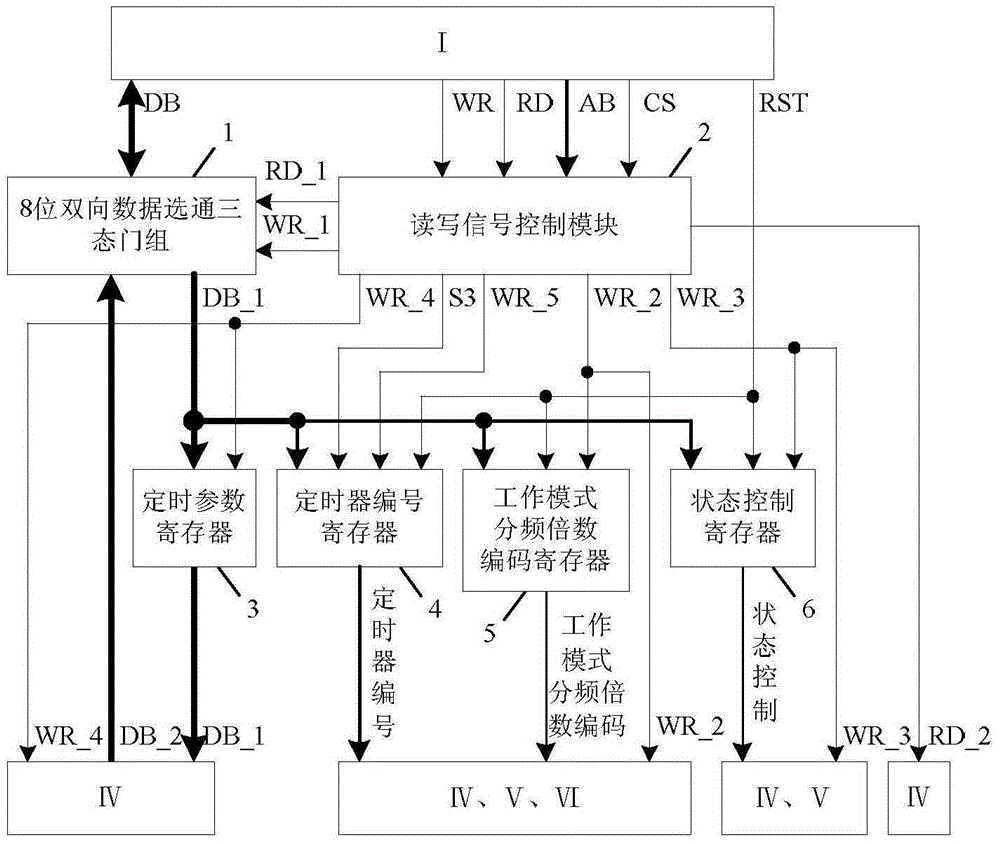

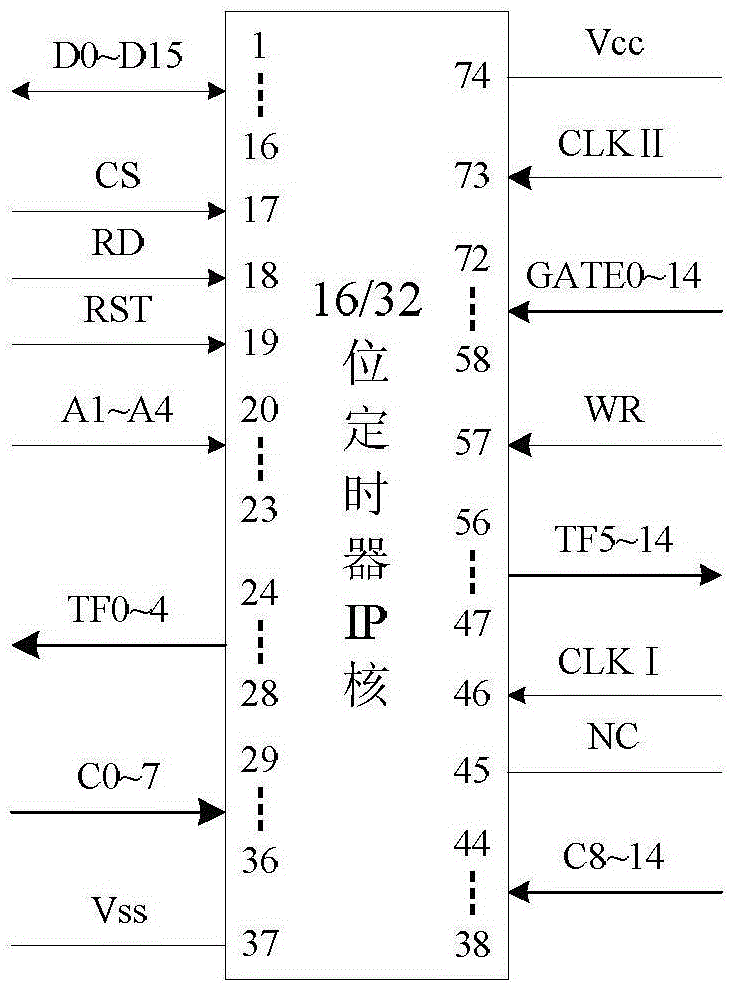

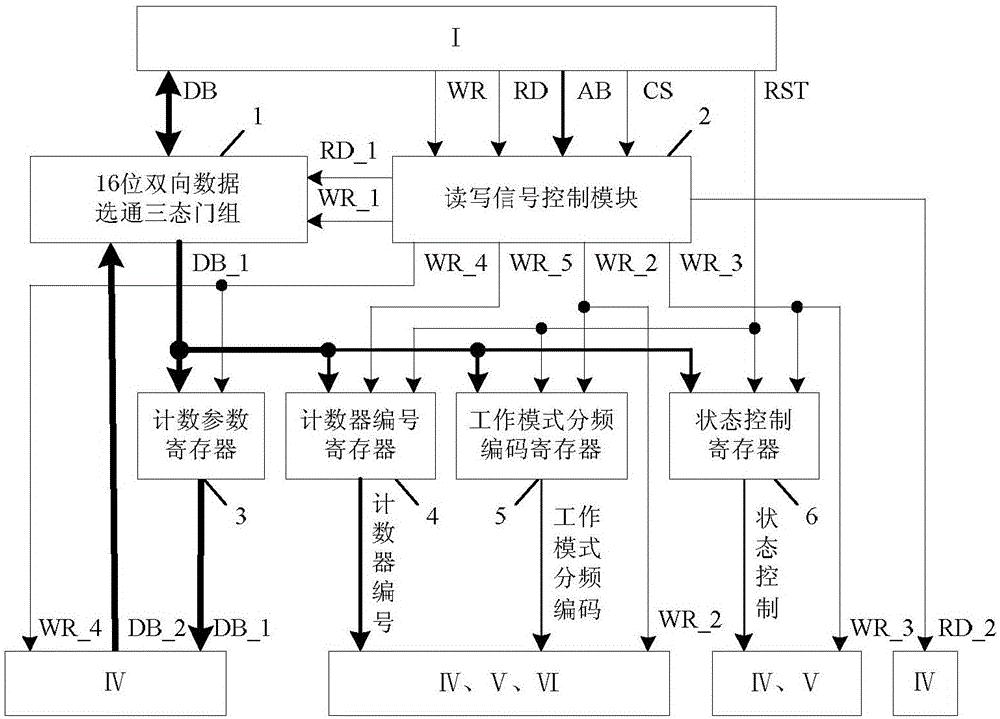

Timer IP (Intellectual Property) core connected with 8-bit microprocessor application system and method thereof for realizing timing control of timer

InactiveCN105183430AEasy to program controlHigh time accuracyMachine execution arrangementsDecompositionIntellectual property

The invention discloses a timer IP (Intellectual Property) core connected with an 8-bit microprocessor application system. The timer IP core comprises a data input / output and command word decomposition storage control module, a pulse 12 frequency divider, a timing processing control module, a timer overflow flag control module and an input gating selection control module. An FPGA (Field Programmable Gate Array) is applied to design the timer IP core formed by a hard connection control circuit, the timer IP core is provided with fourteen 16-bit timers, wherein twelve 16-bit timers can form six 32-bit timers, one command word sets a working mode and selects the reference clock frequency division multiple of the timer, and the other command word controls a working state. The program execution time of the 8-bit microprocessor is not occupied except that the 8-bit microprocessor carries out the operations, including function and state setting, timing parameter transmission and current timing value reading, on the timer. Each 16-bit / 32-bit timer has a function of automatically reloading the timing parameter, so that timing precision is improved. The requirements of the timing of a plurality of timers and the timing control of a system can be met.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH +1

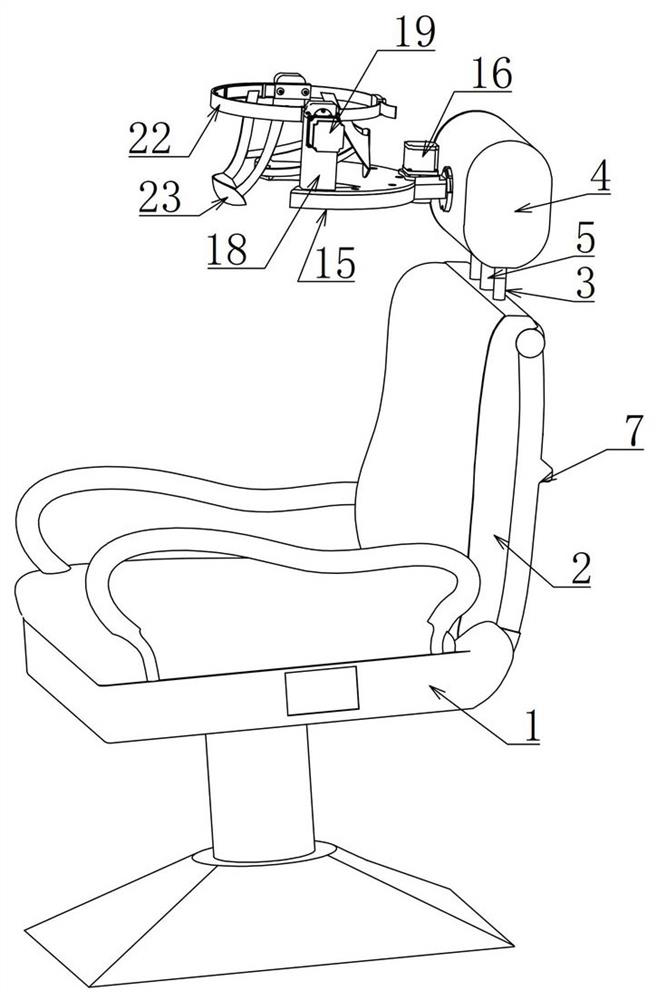

Intelligent angle-measurement multifunctional auxiliary treatment chair for cervical spondylosis

The invention relates to the technical field of medical devices, in particular to an intelligent angle-measurement multifunctional auxiliary treatment chair for cervical spondylosis, and aims to solve problems that with acceleration of pace of life, long-term overtime working, driving and the like of young people are increasingly common and patients with cervical spondylosis are continuously increased. Front flexion and rear extension, left and right rotation, and left and right lateral flexion and traction are independently controlled by stepping motors for independent movement and sequential and circular movement, and program control is facilitated; Height of a chair seat and a head fixing device can be freely adjusted, and individualized treatment can be achieved for patients with different illness conditions; the patients can freely change body positions between 90 degrees (sitting posture) and 180 degrees (lying posture), movement angles and traction forces have program and mechanical dual protection functions, and neck movement angles and the traction forces are strictly controlled within an allowable range; and a wireless device is used to meet operation requirements of the patients at different treatment body positions, such that the intelligent angle-measurement multifunctional auxiliary treatment chair can realize self-service treatment, and is suitable for hospital treatment and family treatment.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

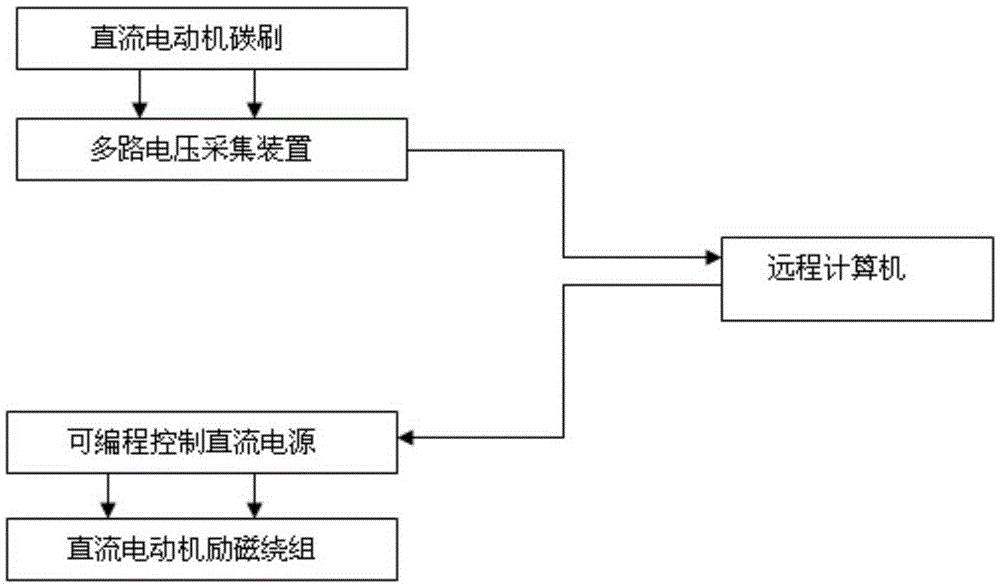

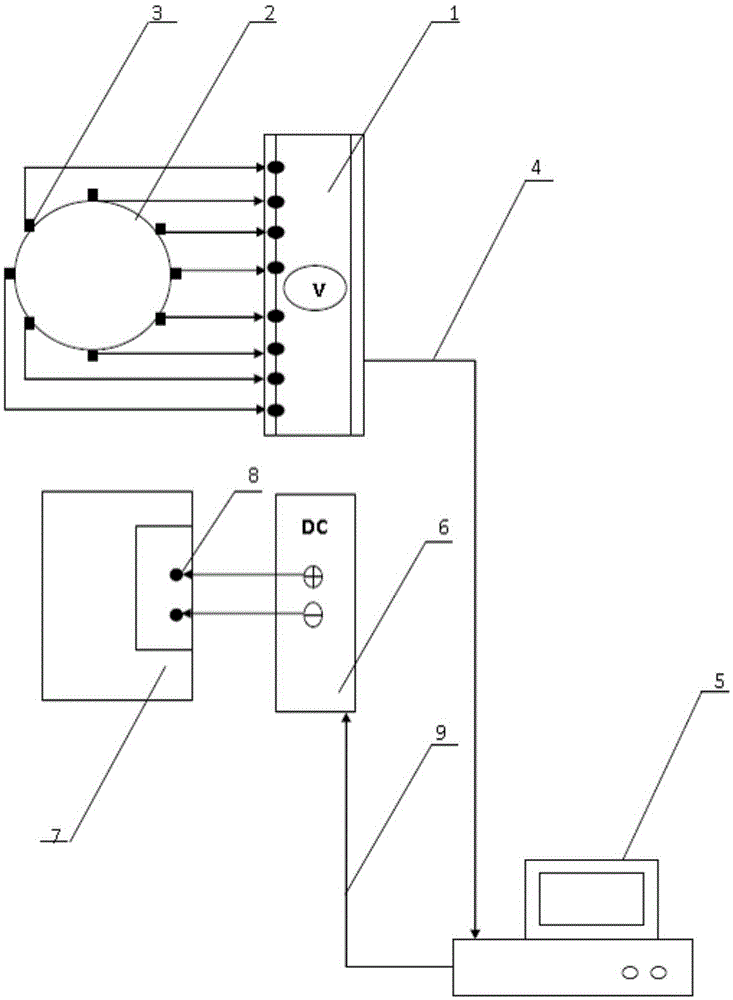

Automatic positioning device for neutral line of direct current motor

The invention provides an automatic positioning device for a neutral line of a direct current motor. A remote computer controls a programmable direct current power supply to provide direct current voltage for an excitation winding of the direct current motor in an interrupted manner, and the remote computer acquires induced voltage in an armature winding of the direct current motor from each carbon brush via a multichannel voltage acquisition device, displays and compares uploaded voltage data, and calculates the position of the neutral line of the direct current motor. According to the automatic positioning device, the structure is simple, the automation degree is high, the wiring is convenient, automatic, accurate, and rapid positioning of the neutral line of the direct current motor is realized, the adjusting time of the neutral line of the direct current motor is shortened, and on-site debugging personnel is reduced; besides, the computer analyzes and calculates the voltage data of each carbon brush via software so that manual errors are avoided, and guarantee is provided for safety operation of the direct current motor.

Owner:HARBIN ELECTRIC MASCH CO LTD

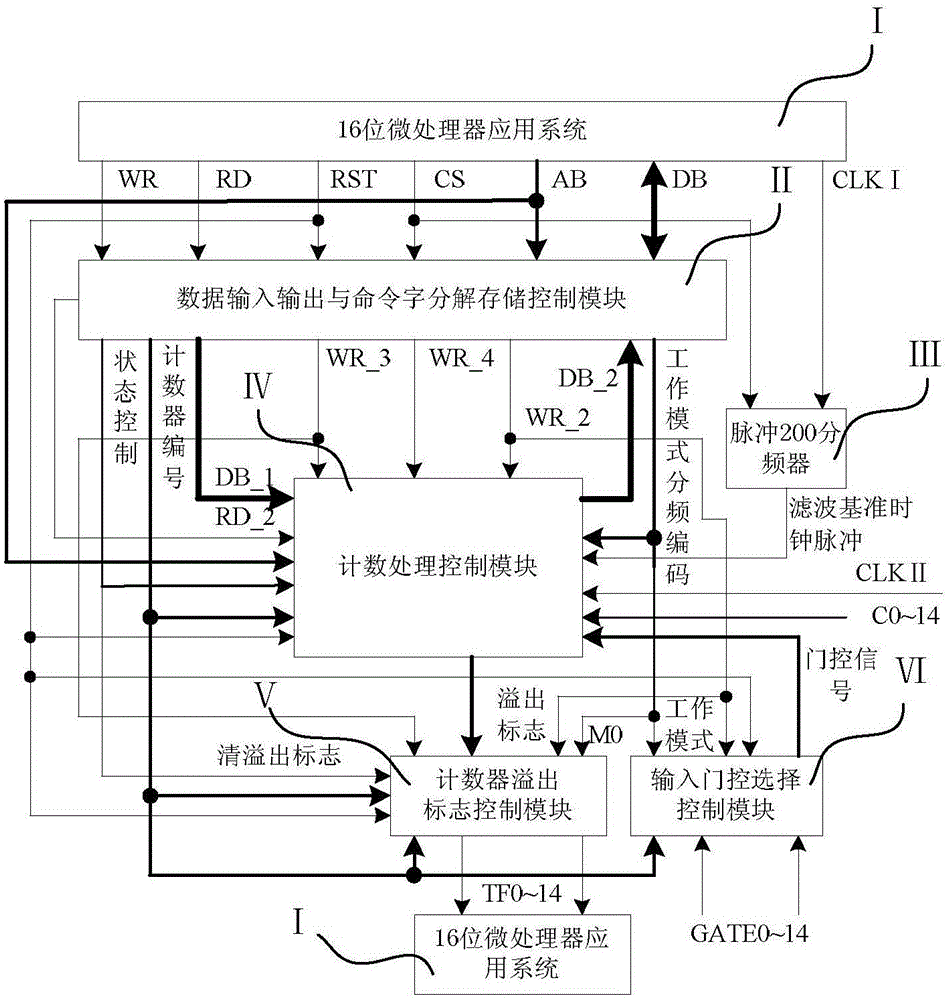

Counter IP core connected with 16-bit microprocessor application system, and counter counting control realization method thereof

InactiveCN105117200AEasy to program controlGood value for moneyMachine execution arrangementsComputer architectureDecomposition

A counter IP core connected with a 16-bit microprocessor application system comprises a data input / output and command word decomposition storage control module, a pulse 200 frequency divider, a counting processing control module, a counter overflow sign control module and an input gated selection control module; the FPGA design counter IP core is in hard connection with a control circuit; the counter IP core comprises 15 16-bit counters, wherein 14 counters can form 7 32-bit counters; one command word sets the work mode of the counter, sets counting filtering reference clock frequency division times, and controls the work state; the counter IP core only uses the 16-bit microprocessor to set functions and states, counting parameter transmission and read counting present value operation of the counters, so program execution time of the 16-bit microprocessor is not used by other programs; each 16 / 32 bit counter has a counting parameter automatic afresh loading function, thus satisfying counting and counting control system demands of many counters.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Motor control intelligent separation and combination system of double-body automobile

ActiveCN102205858ASimple structureEasy to program controlElectric/fluid circuitVehicle bodiesMotor controlEngineering

The invention relates to a motor control intelligent separation and combination system of a double-body automobile. The system mainly solves the technical problem of separation and combination of the double-body automobile. The double-body automobile comprises a primary single-body automobile and a secondary single-body automobile which are arranged in parallel on the left side and the right side. The system comprises a driving feed device arranged on the primary single-body automobile and an enclasping device arranged on the secondary single-body automobile, wherein the driving feed device comprises a connecting screw rod capable of stretching automatically; the enclasping device comprises an enclasping claw matched with the connecting screw rod, and a trigger switch used for controlling the enclasping claw to open and close; the trigger switch is arranged on one side of the enclasping claw; and when the connecting screw rod is connected with the enclasping claw in a matching mode, the top end of the connecting screw rod presses against the trigger switch. The driving feed device and the enclasping device are arranged on the double-body automobile respectively, and the separation and the combination of the two single-body automobiles are realized by matching the driving feed device with the enclasping device. The system is simple in structure and convenient for program control.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

DSP (digital signal processor) based energy-feedback electronic load grid-connected inverting system and control method thereof

InactiveCN102832639BImprove consistencyImprove good performanceEfficient power electronics conversionAc-dc conversionDigital signal processingElectronic load

The invention discloses a DSP (digital signal processor) based energy-feedback electronic load grid-connected inverting system and a control method thereof. The system comprises a main circuit and a control circuit. The main circuit comprises a grid-connected inverting module and an output filter module in sequential connection, the grid-connected inverting module is connected with a 400V DC (direct-current) output end of a booster system, the output filter module is connected with a public power grid phase, and the control circuit comprises a fault protection circuit module, a current voltage sampling and signal processing module, a human-computer interaction module, a DSP embedded system module and a high-frequency driving module. Fully digitalized control of the grid-connected inverting system is realized by a reliability test aiming at low-voltage direct-current power output characteristics for the first time in China, on the basis of the high-frequency PWM (pulse-width modulation) technology and adopting an industrial-level high-performance digital signal processor DSP chip, 400V high-voltage direct-current output by the energy-feedback electronic load booster system is inverted into 220V single-phase power-frequency current, and an output side is connected into a power grid.

Owner:SOUTH CHINA UNIV OF TECH

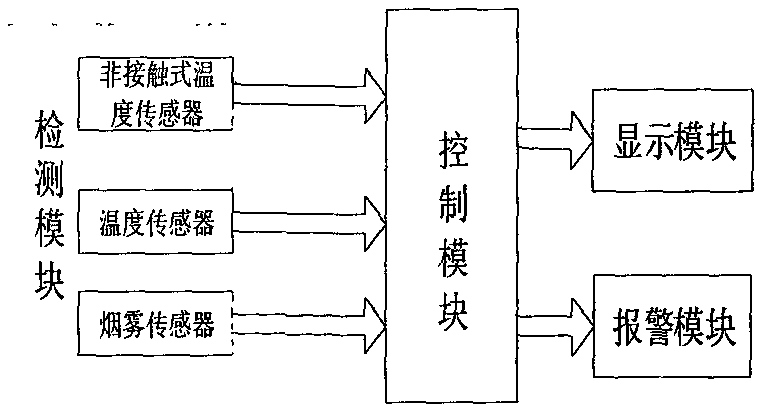

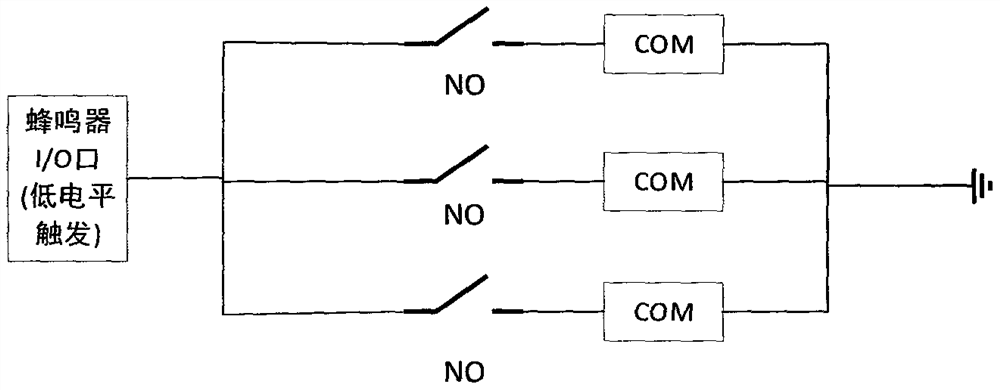

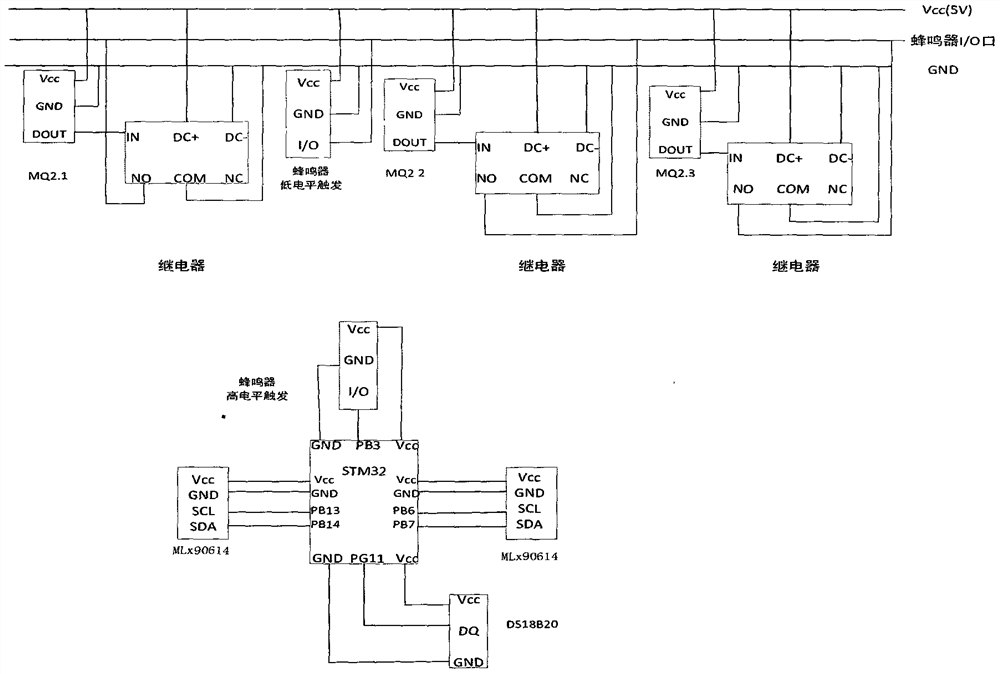

Distributed non-contact measurement and early warning system for vehicle spontaneous combustion phenomenon

InactiveCN111951512AHigh precisionShort response timeFire alarm electric actuationFire alarm smoke/gas actuationData displayEarly warning system

The invention relates to a distributed non-contact measurement early warning system for a vehicle spontaneous combustion phenomenon, which is specifically applied to early warning of the vehicle spontaneous combustion phenomenon to achieve real-time monitoring and early warning of vehicle temperature and smoke concentration. Aiming at a fire disaster caused by a vehicle circuit system fault and threatening human life, the invention provides an early warning monitoring system, which comprises a detection module taking a smoke sensor MQ-2, a non-contact infrared temperature sensor MLx90614 and atemperature sensor DS18B20 as cores, a minimum system taking an STM32F103ZET6 chip as a core, an additional display module TFT LCD screen and an alarm module active buzzer, the system can achieve thefunctions of real-time data measurement, data display and early warning, is practical and intelligent, is simple in design, is wide in application range, is high in universality, is lower in cost, and is convenient to use.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

A tray automatic push-pull access device

The invention provides a push-pull pallet automatic storing and taking device. The storing and taking device is characterized in that two sets of guide rails are fixed on the upper surface of a stacking machine platform; a longitudinal beam in a supporting frame is located on one side of the stacking machine platform, a main beam is located on the other side of the stacking machine platform; supporting shafts are arranged at the two ends of the inner cavity of the main beam respectively; driven chains are arranged on the supporting shafts at the two ends of the inner cavity of the main beam ina sleeved mode, so that the driven chains penetrate through the supporting shafts at the two ends and penetrate through the inner cavity of the main beam to form an operation loop; two drag hook components are connected to the driven chains in a chain mode; one end of a nut seat connecting plate is fixed on the inner side surface of the main beam, and the other end of the nut seat connecting plate is fixed on the upper surface of the longitudinal beam. The device has the advantages that the structure is simple and compact, the operation is light and efficient, and the storing and taking tasksof the pallets of various sizes can be completed by changing the position of the drag hooks

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

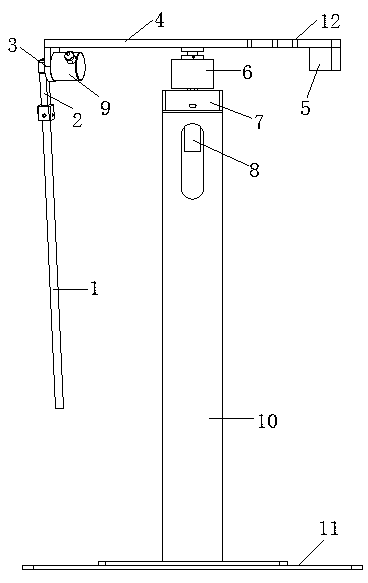

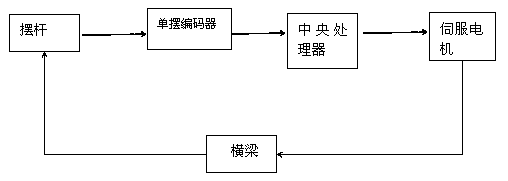

Rotary type inverted pendulum with counterweight

InactiveCN105511501ASmall footprintLess external interferenceControl using feedbackControl theoryInverted pendulum

A rotary type inverted pendulum with a counterweight comprises the components of a vertical pole, the counterweight, a crossbeam and a swing rod. The bottom of the vertical pole is fixed to a vertical column base. The vertical column is vertically arranged on a horizontal experimental table through the vertical column base. The upper part of the vertical column is internally provided with a servo motor. The servo motor is connected with a central processing unit and a power supply. The crossbeam is arranged at the top of the vertical column. The servo motor can drive the crossbeam to rotate at the top of the vertical column. The swing rod is suspended at one end of the crossbeam. The end of the crossbeam is also provided with a simple pendulum encoder. The simple pendulum encoder is connected with the servo motor and the central processing unit. The simple pendulum encoder can recode a deviation angle between the swing rod and the vertical direction in the rotation process of the crossbeam. The counterweight is fixed to the crossbeam. The counterweight is used for keeping the balance of the crossbeam. According to the rotary type inverted pendulum with the counterweight, a relatively small external force interference is realized in an experiment process; the crossbeam is provided with the counterweight and the crossbeam can be adjusted to realize balance, thereby performing a function of protecting the servo motor.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

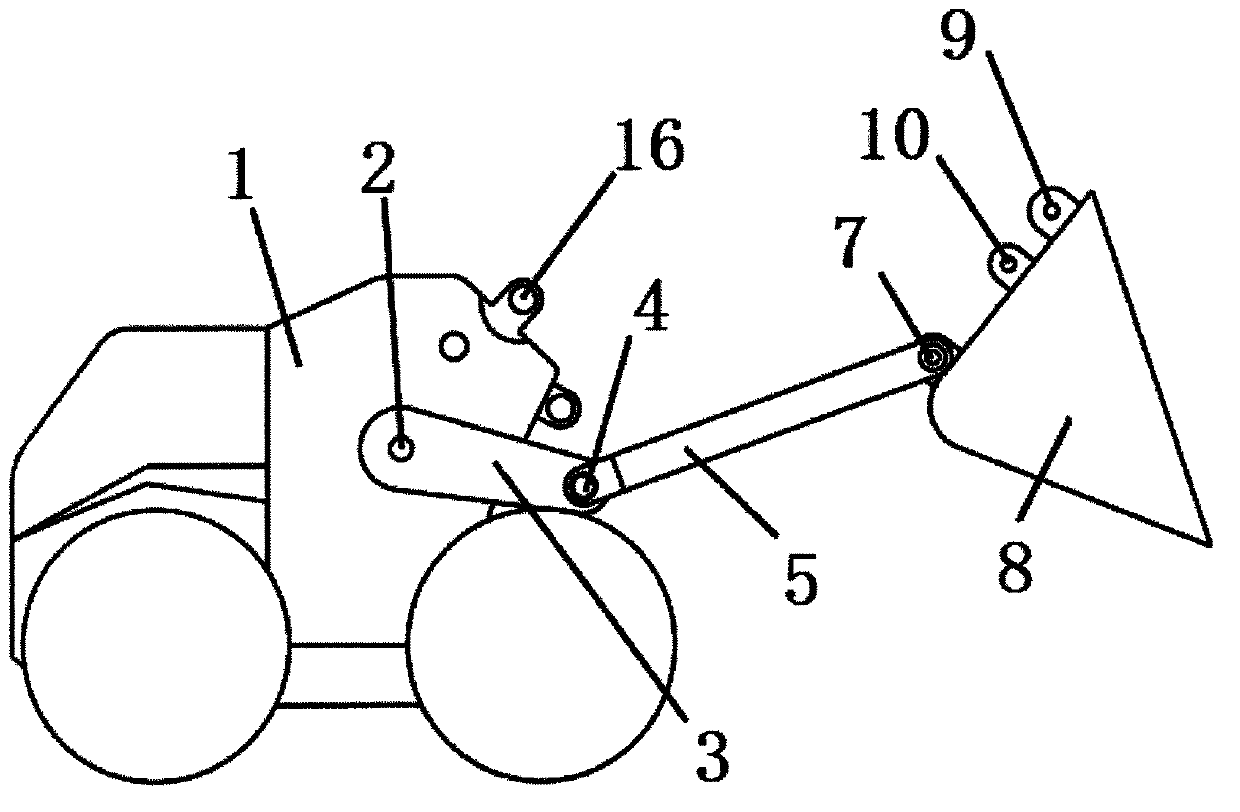

Controllable-mechanism type heavy-duty loader with high bearing capacity

InactiveCN102535545ALight weightImprove reliabilityMechanical machines/dredgersShock resistanceControl theory

The invention relates to a controllable-mechanism type heavy-duty loader with high bearing capacity, which comprises a double-large-arm mechanism, a large arm lifting branch chain, a bucket overturning branch chain, a bucket, a travelling device and a stand, wherein the stand is arranged on the travelling device; the double-large-arm mechanism is articulated on the stand, and the other end of the double-large-arm mechanism is articulated with the bucket; the large arm lifting branch chain is used for controlling large arms to ascent and descend; the bucket overturning branch chain is used for controlling the bucket to overturn; the large arm lifting branch chain and the bucket overturning branch chain are respectively driven by a servo motor arranged on the stand; and the large arm lifting branch chain is matched with the bucket overturning branch chain, so that the loading operation of the heavy-duty loader can be completed. The controllable-mechanism type heavy-duty loader with high bearing capacity not only overcomes the defects that a hydraulic element of the traditional hydraulic loader is high in manufacturing cost, complicated in maintenance and the like, but also is compact in structure, less in the number of rod pieces, high in bearing capacity and reliability, and strong in shock resistance compared with other controllable-mechanism type loaders, and the large heavy-duty loader manufacture is facilitated.

Owner:GUANGXI UNIV

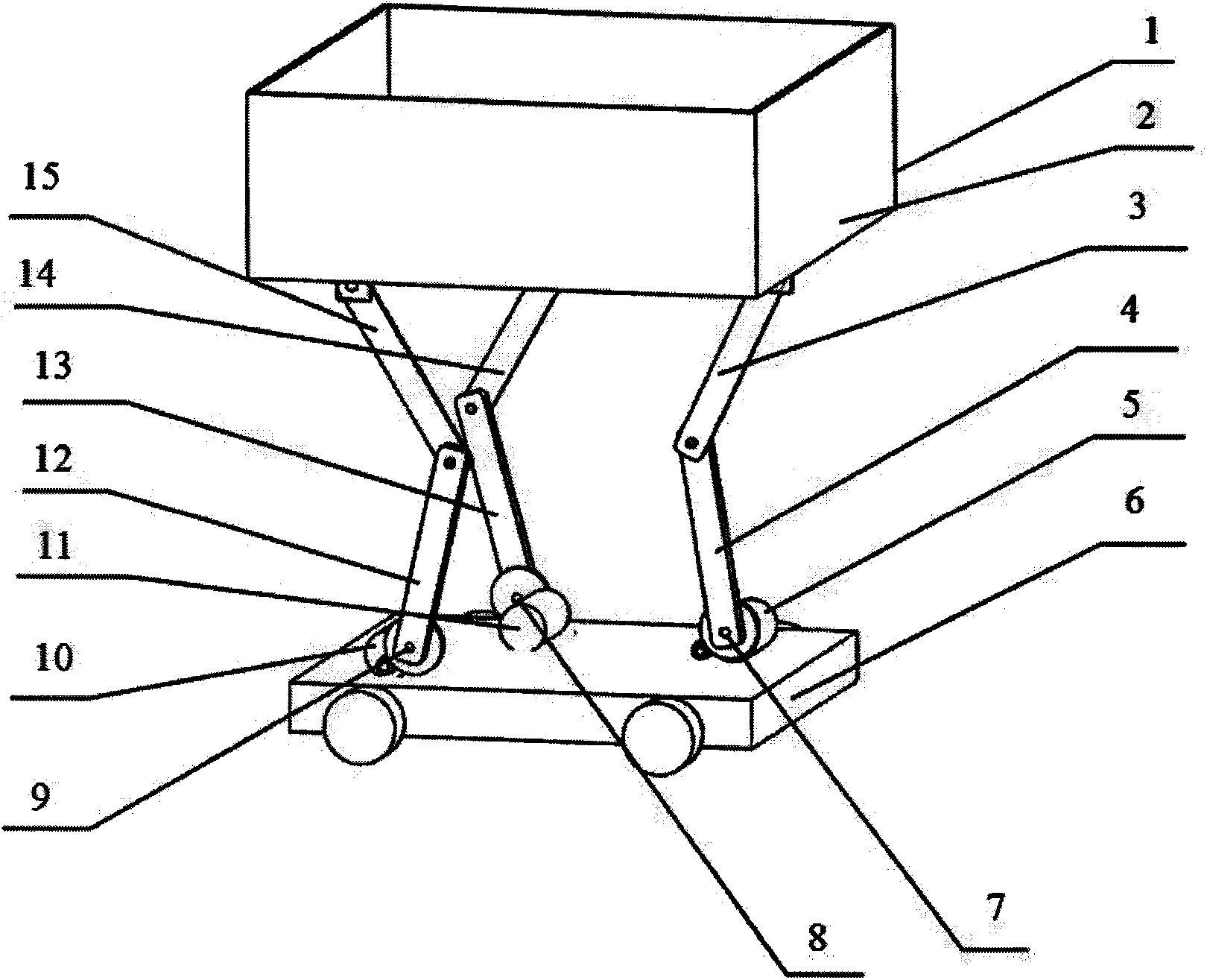

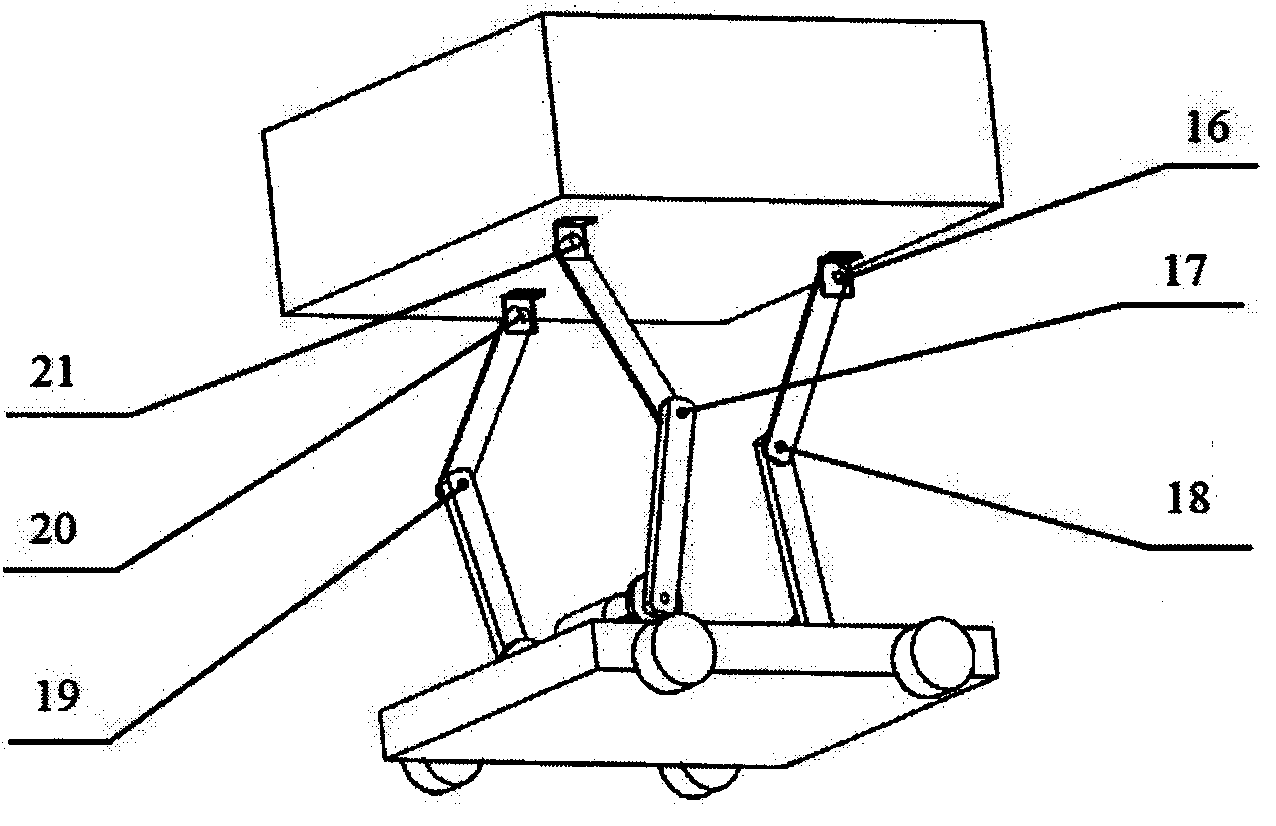

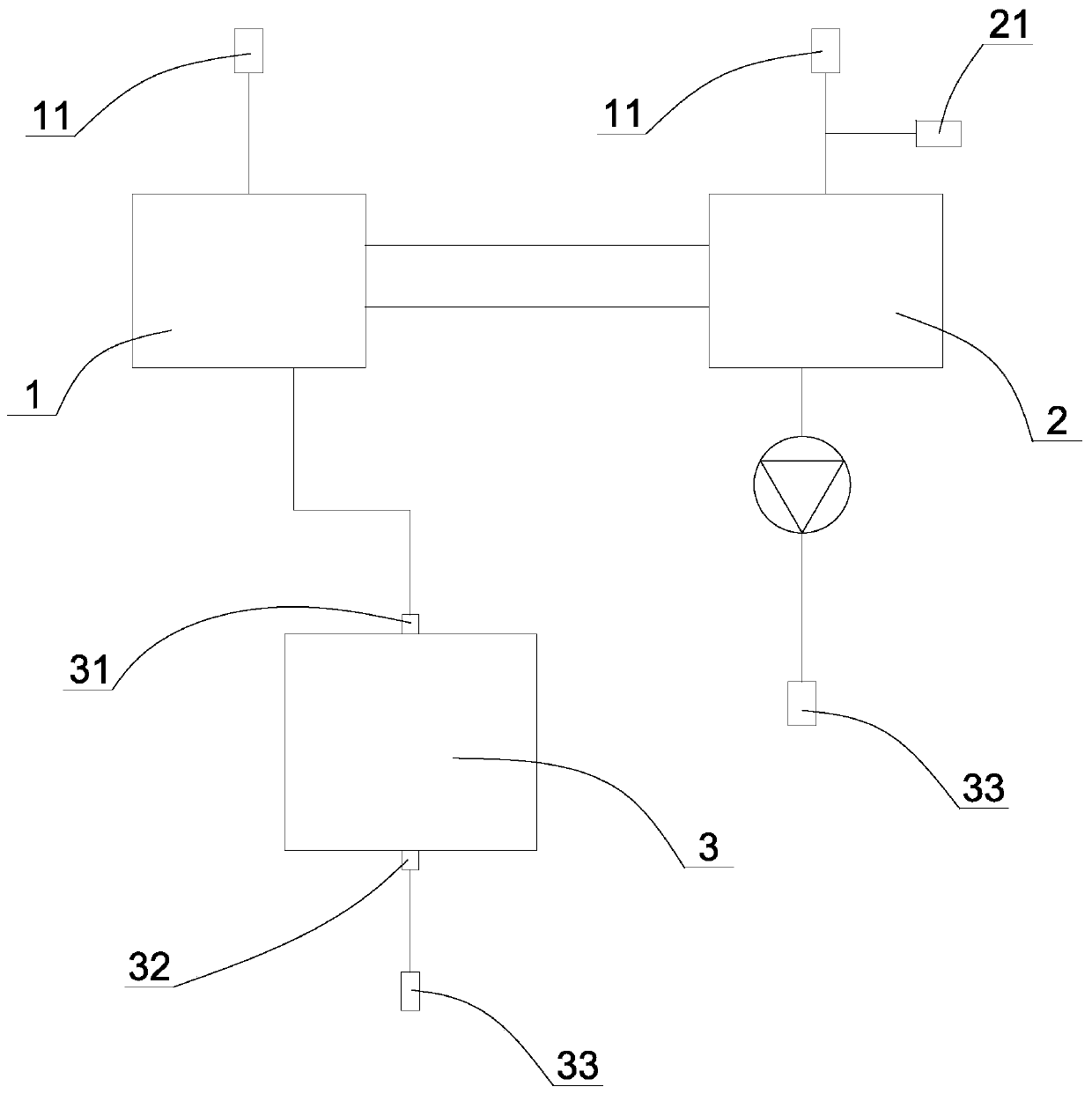

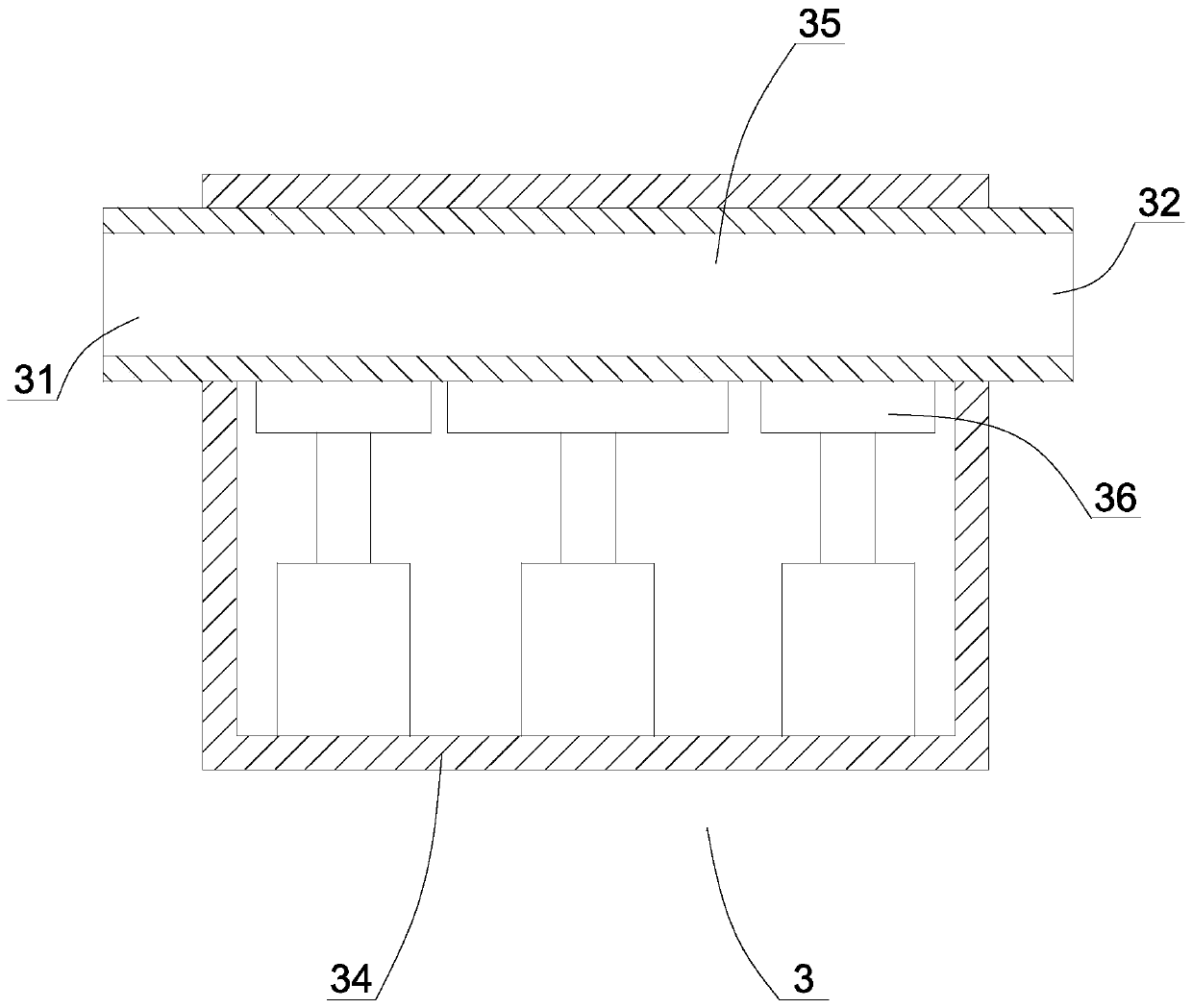

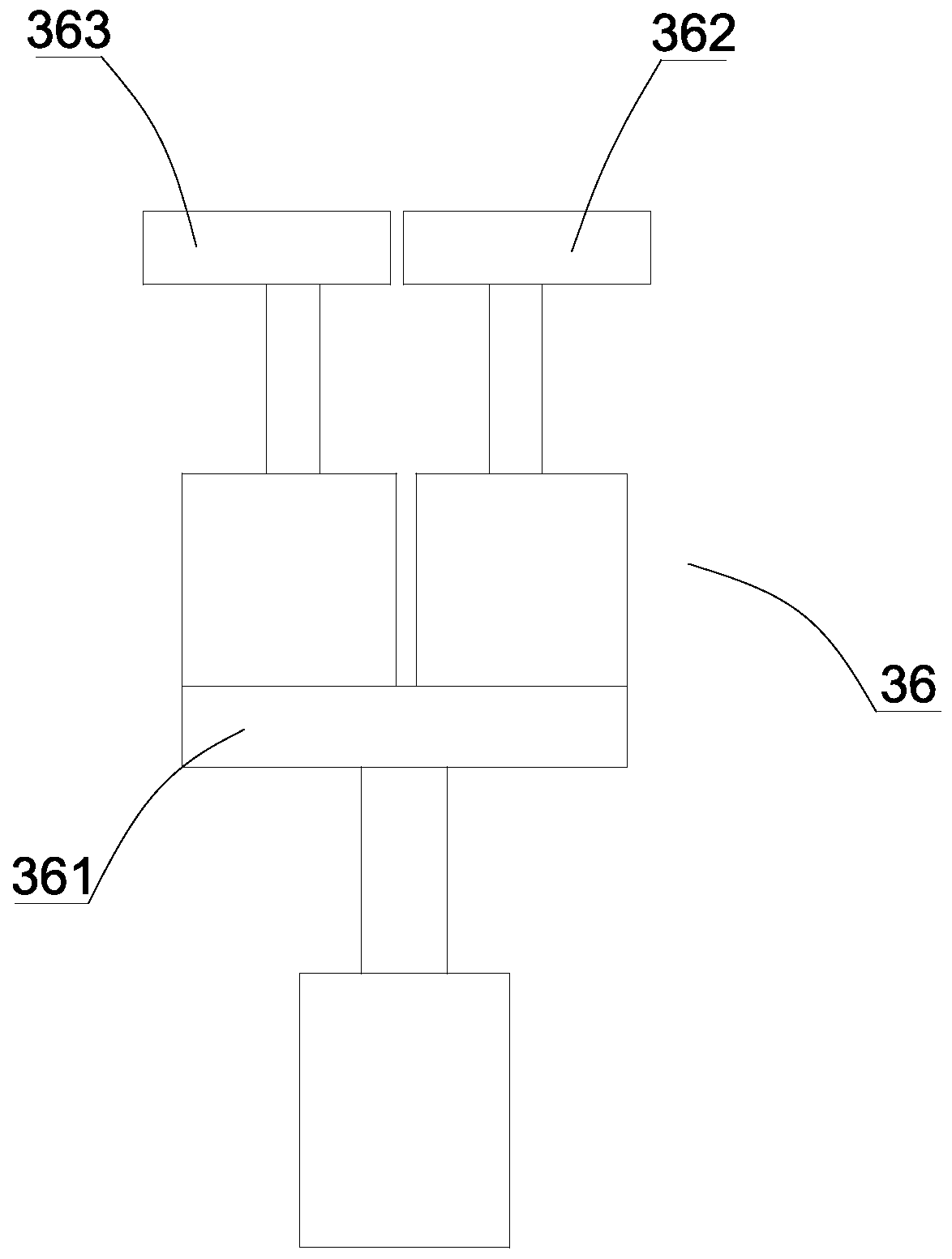

Multifunctional household lifting trolley

A multifunctional household lifting trolley comprises a walking device, a first lifting branched chain, a second branched chain, a third branched chain and a working platform. Each lifting branched chain is composed of a driving rod and a connecting rod, the driving rods are driven by a servo motor to rotate to drive the corresponding connecting rods to rotate, and therefore the lifting of the working platform is achieved. The working platform is composed of a bottom plate and a guard bar, the working platform and the lifting branched chains can be dismounted conveniently through the bottom plate and the guard bar, and the lifting branched chains and the walking device can be dismounted. According to the multifunctional household lifting trolley, the characteristics of an ordinary trolley and the characteristics of a lifting platform are ingeniously combined. The multifunctional household lifting trolley is easy to manufacture, small in size, convenient to use, high in practicability, wide in application range and very suitable for modern household using.

Owner:GUANGXI UNIV

Rolling mill hydraulic pipeline cleaning device

ActiveCN110735143ADoes not affect delivery efficiencyReduce maintenance costsHollow article cleaningOil canLiquid storage tank

The invention discloses a rolling mill hydraulic pipeline cleaning device. The rolling mill hydraulic pipeline cleaning device comprises a liquid storage tank, a hydraulic oil tank and a cleaning pump, a liquid inlet of the cleaning pump is connected with the liquid storage tank, a liquid outlet of the cleaning pump is provided with a liquid conveying pipe which can be connected with a to-be-cleaned hydraulic pipeline, the liquid storage tank is provided with a liquid return pipe which can be connected with the to-be-cleaned hydraulic pipeline, the cleaning pump comprises a shell, an elastic pipe arranged in the shell and a plurality of extrusion heads, the extrusion heads are connected with a piston rod of an oil cylinder so that the extrusion heads can move vertically relative to the elastic pipe, each extrusion head has an extrusion position where the extrusion head is attached to the elastic pipe and a releasing position where the extrusion head is away from the elastic pipe, and the oil cylinder is connected with a hydraulic pump through an electrically controlled main reversing valve so that each extrusion head can stretch out and retract in sequence according to certain interval time. According to the rolling mill hydraulic pipeline cleaning device, the cleaning efficiency can be remarkably improved, secondary pollution is avoided, automatic collection of hydraulic oil can be achieved, and then the accuracy of cleanliness detection of the hydraulic oil can be improved.

Owner:CHINA THIRD METALLURGICAL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com