Rolling mill hydraulic pipeline cleaning device

A technology for hydraulic pipelines and cleaning devices, applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of inconvenient detection of cleaning effects, low cleaning efficiency, and high cleaning costs, and avoid cleaning dead corners. The effect of reducing maintenance costs and facilitating processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

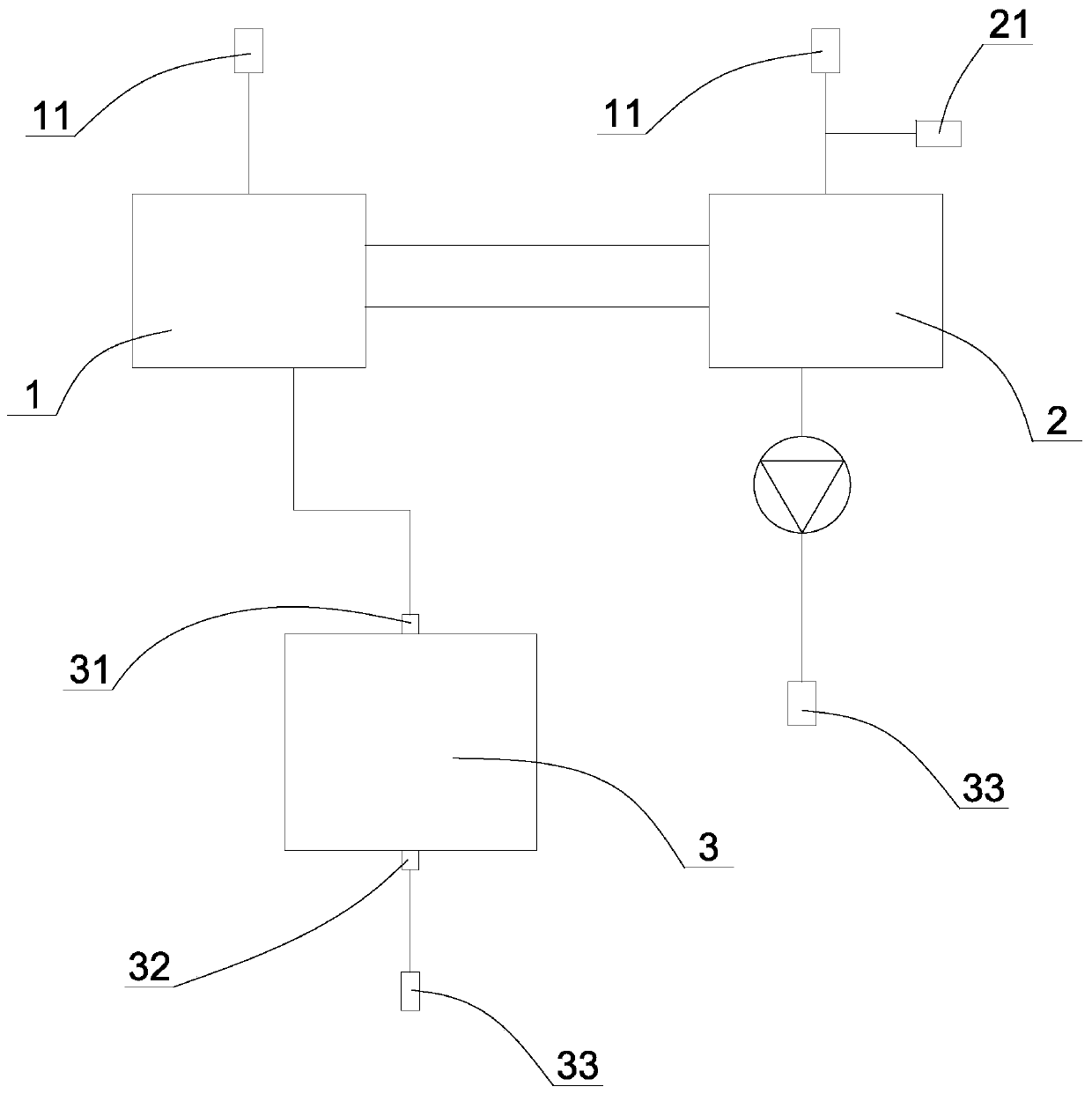

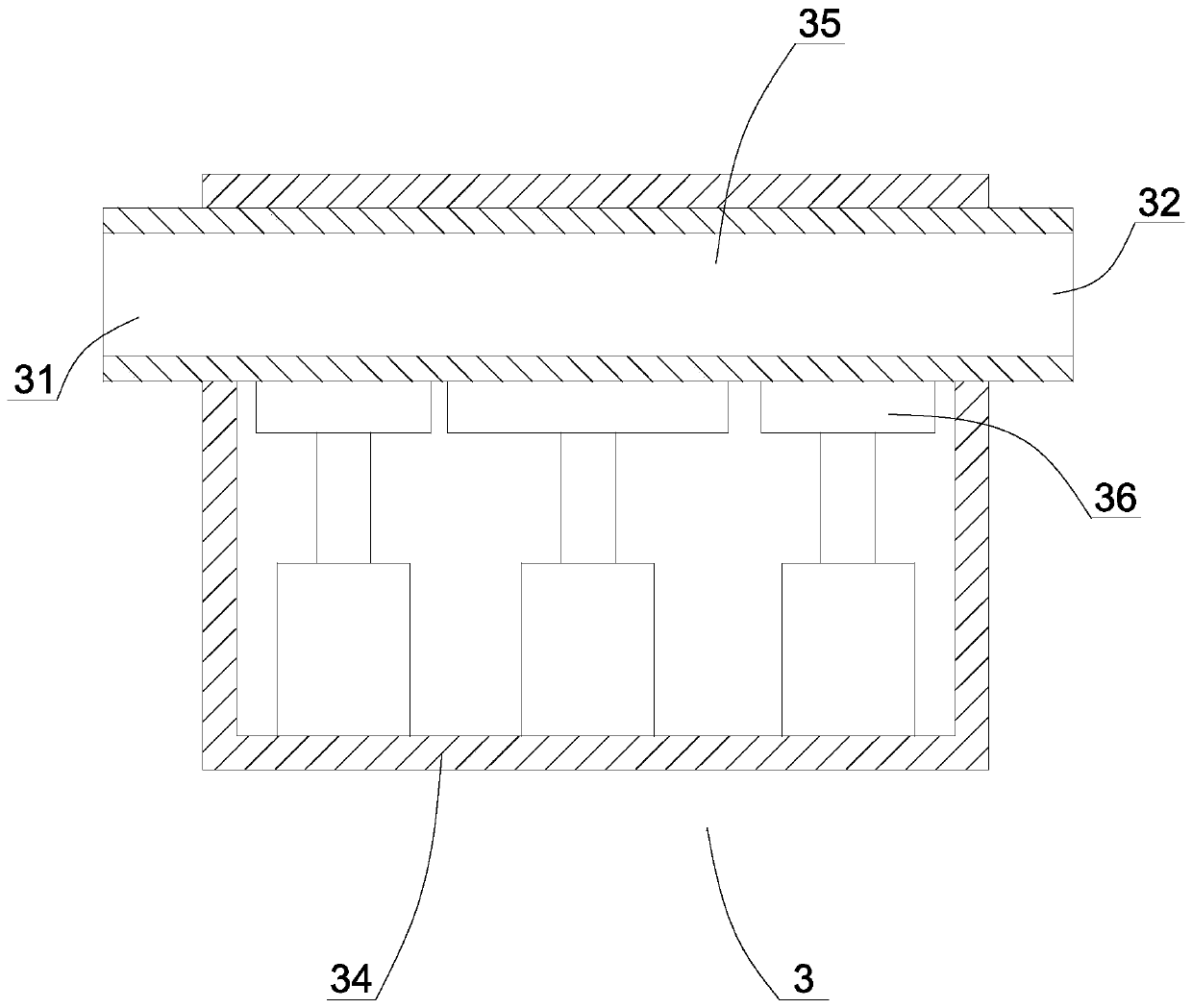

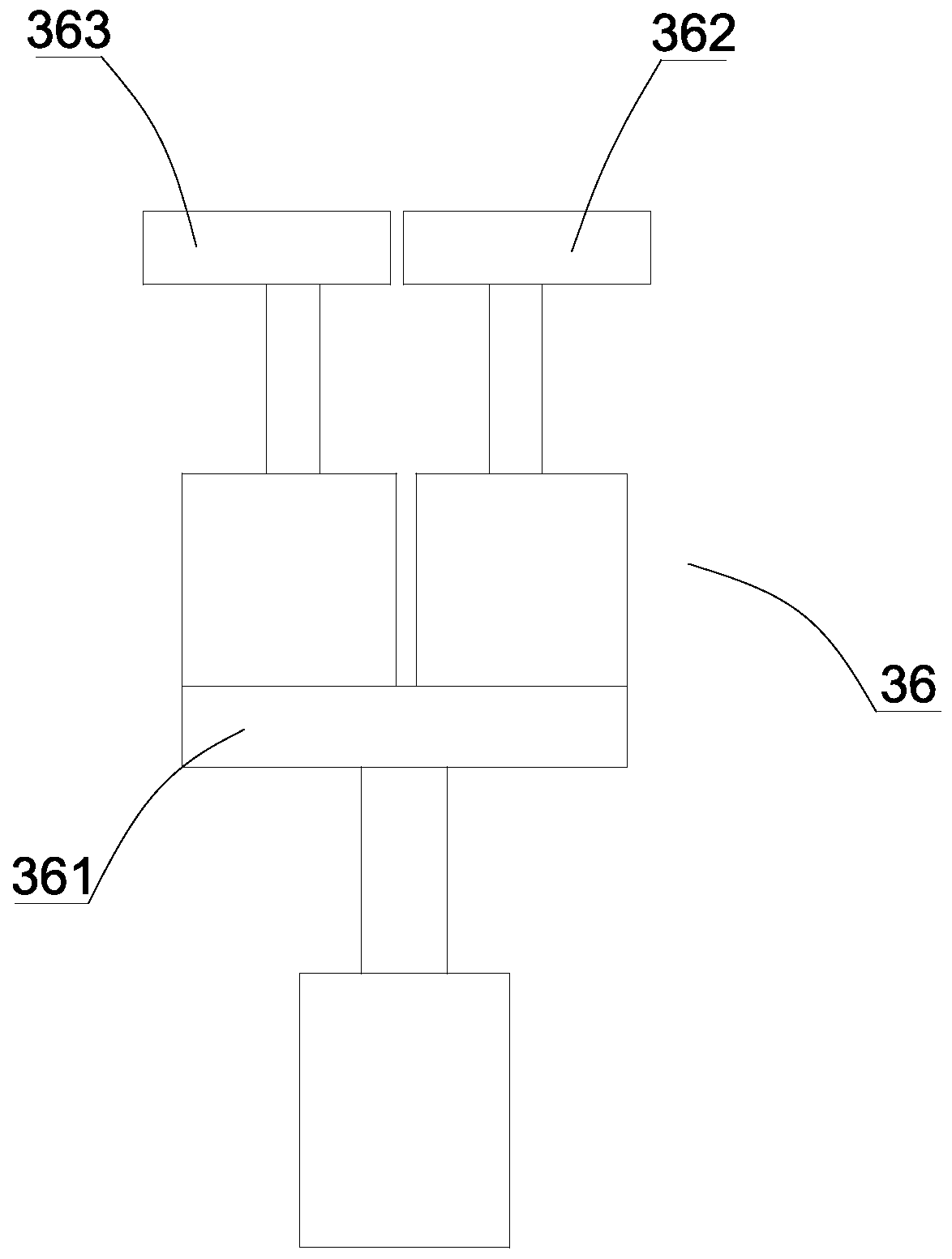

[0043] A rolling mill hydraulic pipe cleaning device, which is suitable for cleaning the hydraulic pipes in the hydraulic system of the rolling mill in the metallurgical industry before official use, so as to ensure the normal use of the hydraulic system. Of course, the hydraulic system also includes a hydraulic station and hydraulic control components , hydraulic actuators and other respected equipment and devices, which will not be described in detail here. Such as figure 1 As shown, it specifically includes a liquid storage tank 1, a hydraulic oil tank 2, a cleaning pump 3 with a liquid inlet 31 and a liquid outlet 32, the liquid inlet of the cleaning pump is connected to the liquid storage tank through a pipeline provided with a valve, and the cleaning pump The liquid outlet is provided with an infusion pipe 33 that can be connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com