Continuous mobile waterpower drive device of nuclear reactor control rod

A nuclear reactor and hydraulic drive technology, applied in the control of nuclear reactions, reactors, nuclear engineering, etc., can solve the problem that the control rods are not continuous, and achieve the effects of easy operation and programmed control, good safety and stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

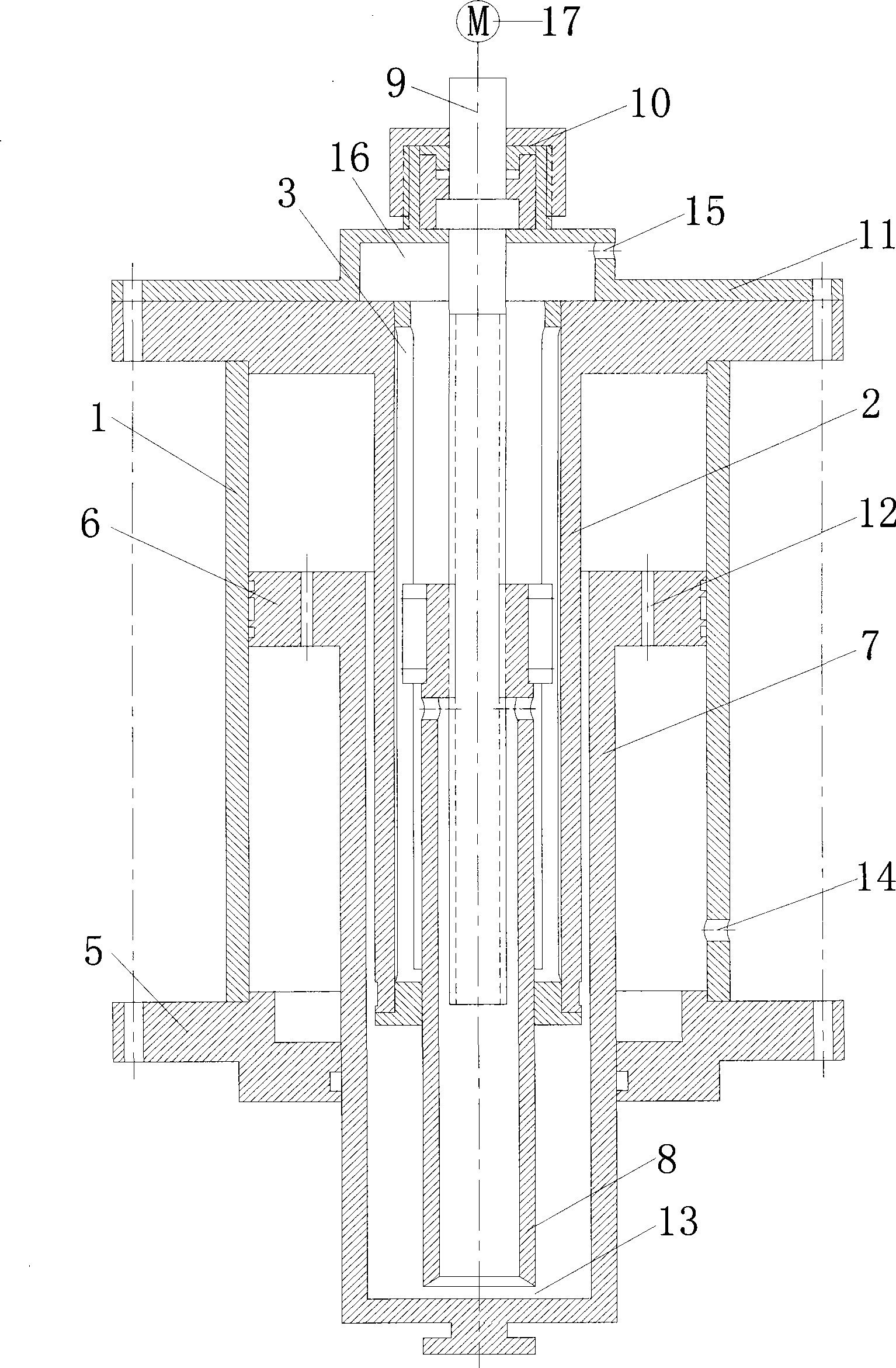

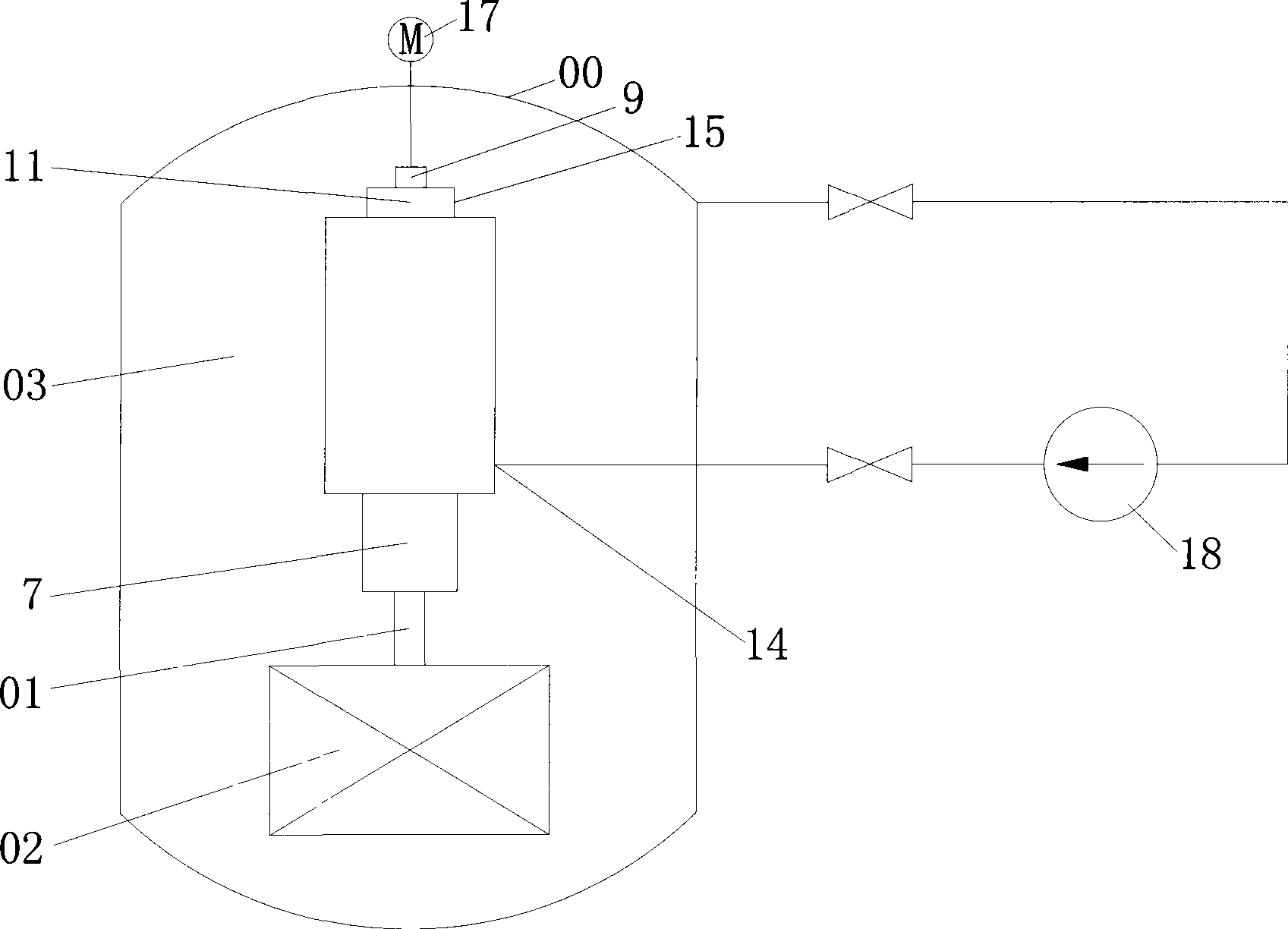

[0017] combine figure 1 , the specific composition of the hydraulic driving device for the control rod of the continuous mobile nuclear reactor includes a driving cylinder 1, an inner sleeve 2, a chute sleeve 3, a lower end cover 5, a piston 6, a hollow piston rod 7, a servo tube 8, a screw 9 and a stopper. Channel assembly 10, buffer chamber cover 11 and its power source (motor 17 and water pump 18 (see figure 2 )); wherein, the integrated piston 6 and hollow piston rod 7 are inserted coaxially with the drive cylinder 1; the inner sleeve 2 inserted in the hollow piston rod 7 is a flange with an end The cylinder body and part of the outer wall are processed into a plane, so that the arc surface on the outer wall can be slidably matched with the hollow piston rod 7, and the plane on the outer wall and the inner wall of the hollow piston rod 7 can form a working m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com