A light-transmitting and air-permeable cabin for continuous surface forming 3D printing and its operating method

A 3D printing and ventilation cabin technology, applied in the field of 3D printing, can solve the problems of limited photosensitive resin flow characteristics, slow material replenishment, easy deformation, etc., to overcome the inability to print large parts, make up for slow replenishment, and avoid bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

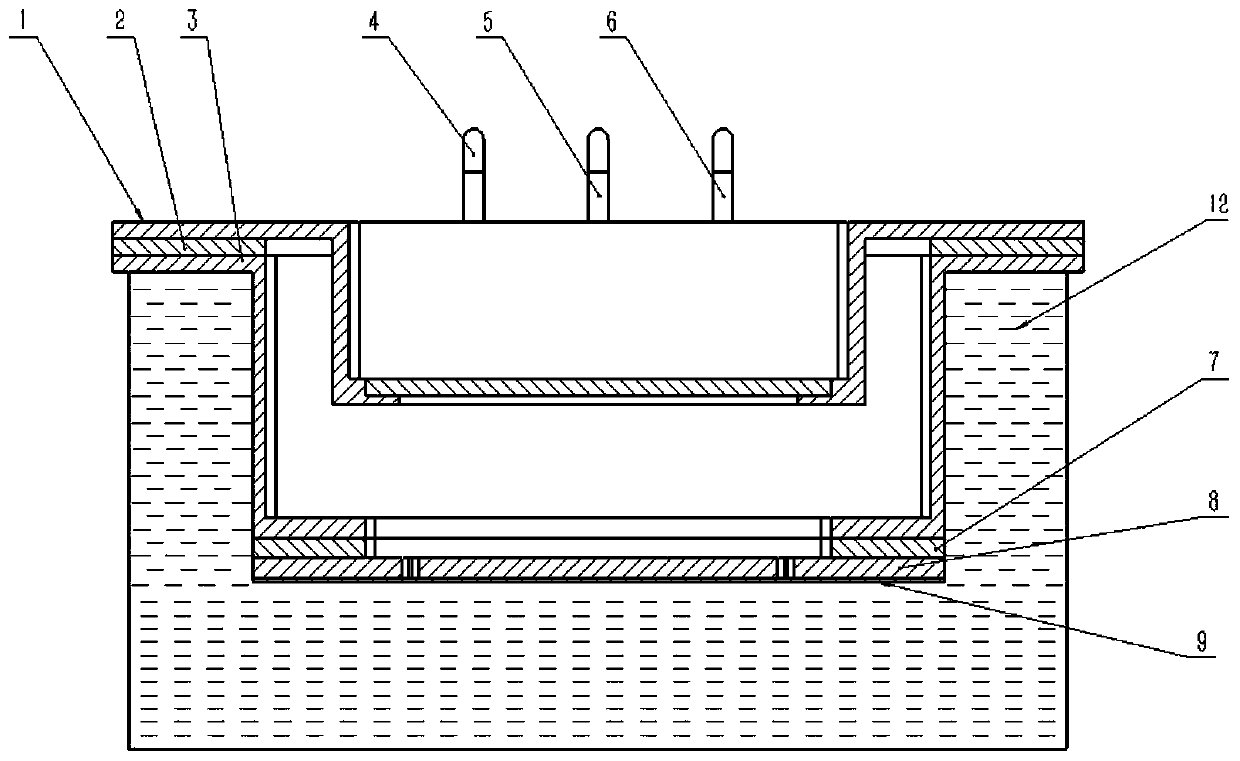

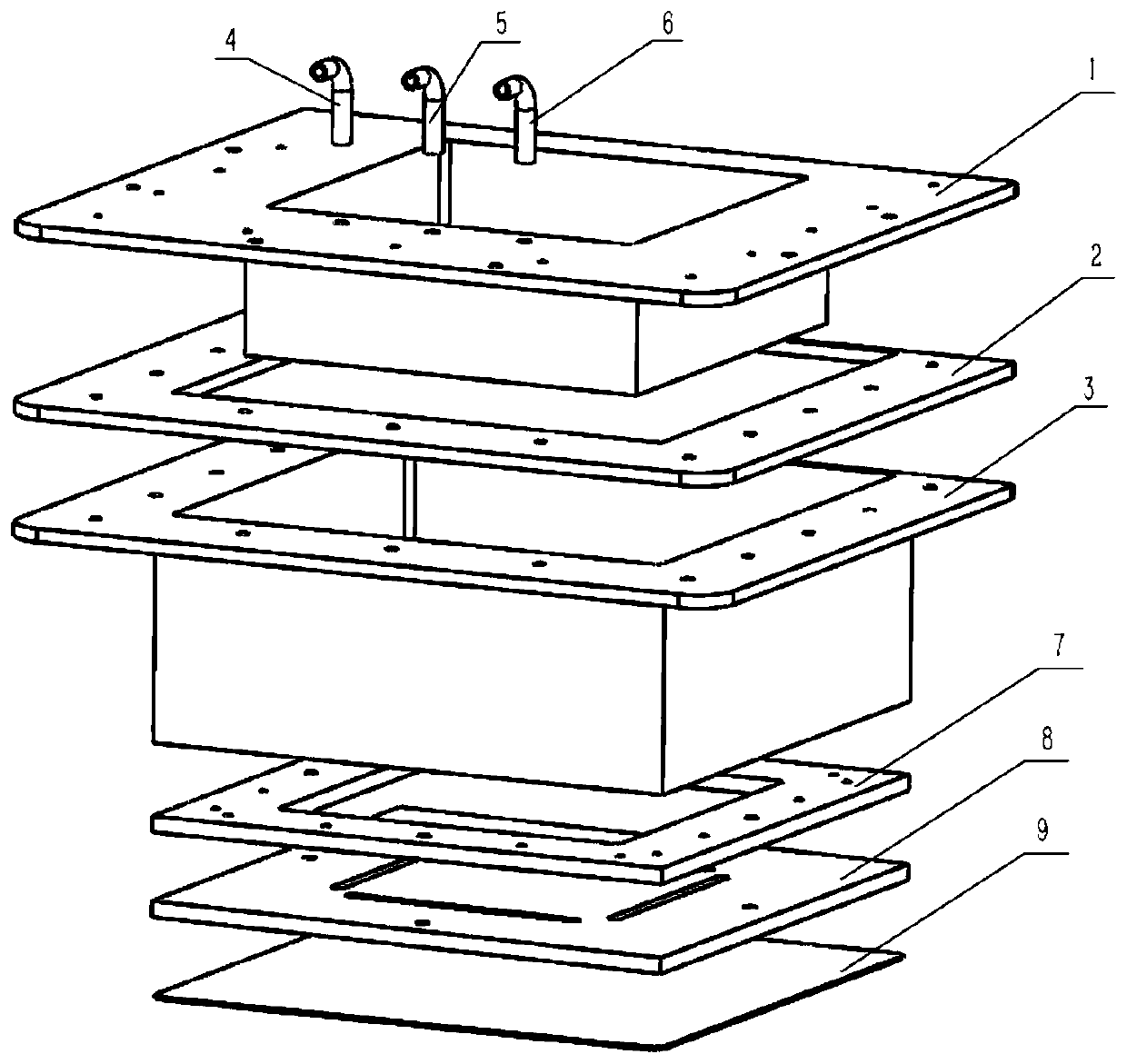

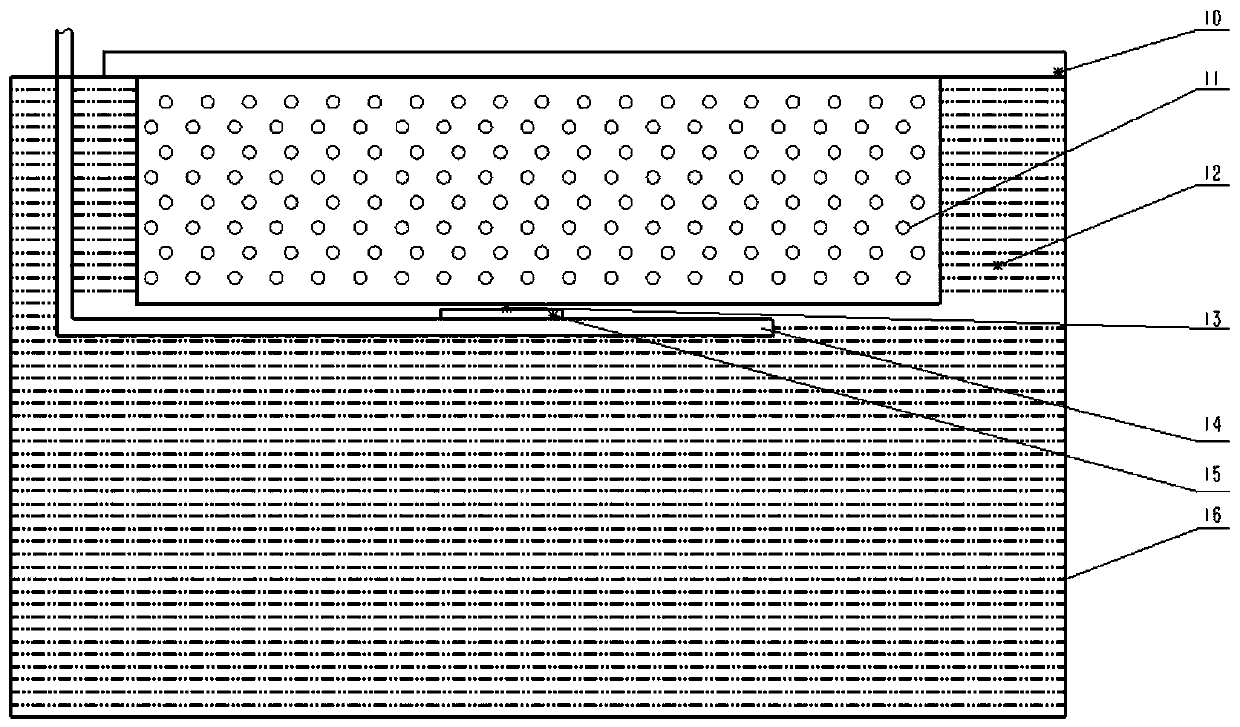

[0027] The present invention is further described below in conjunction with accompanying drawing:

[0028] see Figure 1-Figure 4 , a light-transmitting and air-permeable cabin for continuous surface forming 3D printing, including a cabin body 3, a hatch cover 1, an air supply joint 4, an exhaust joint 5, and a gas-permeable membrane 9; the cabin body 3 is a cylindrical structure with openings at both ends , the air-permeable membrane 9 is sealingly arranged at one end of the cabin body 3, and the other end of the cabin body 3 is sealed with a hatch cover 1 to form a sealed space; the hatch cover 1 is provided with an air supply joint 4 and an exhaust joint 5, and the air supply joint 4 and the exhaust joint 5 are all communicated with the sealed space, and the air supply joint 4 is connected to the air supply system.

[0029] A first sealing gasket 2 is provided between the hatch cover 1 and the cabin body 3, and a detection joint 6 is provided on the hatch cover 1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com