Miniature multi-freedom-degree controllable mechanical type crowd shovel excavating loading mechanism

A technology of loading mechanism and degree of freedom, applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve problems such as few types, low reliability, and small carrying capacity, and achieve Use fewer connecting rods, improve reliability, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of the present invention will be further described below with reference to the accompanying drawings.

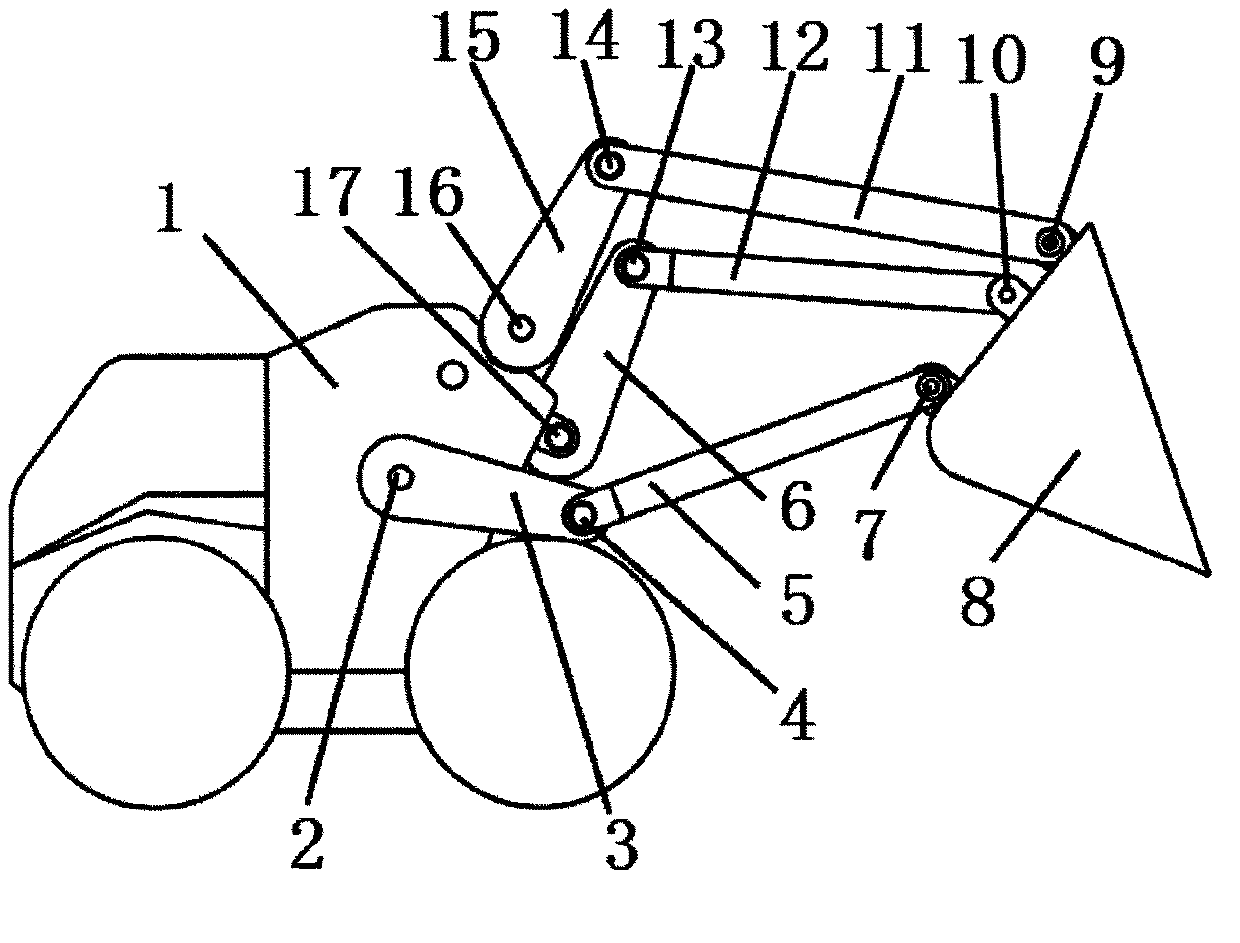

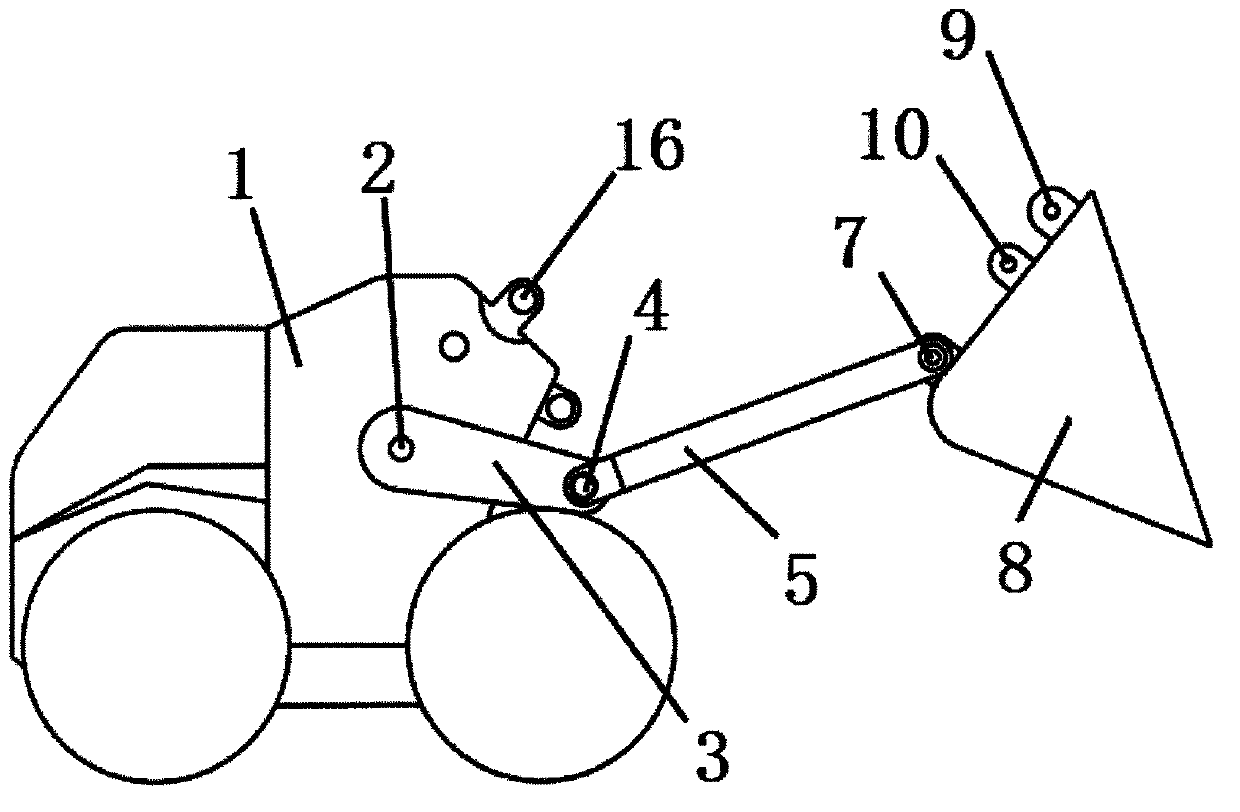

[0023] control figure 1 A miniature multi-degree-of-freedom controllable mechanism-type front shovel excavation loading mechanism includes a frame 1, a first branch chain, a second branch chain, a third branch chain, and a bucket 8.

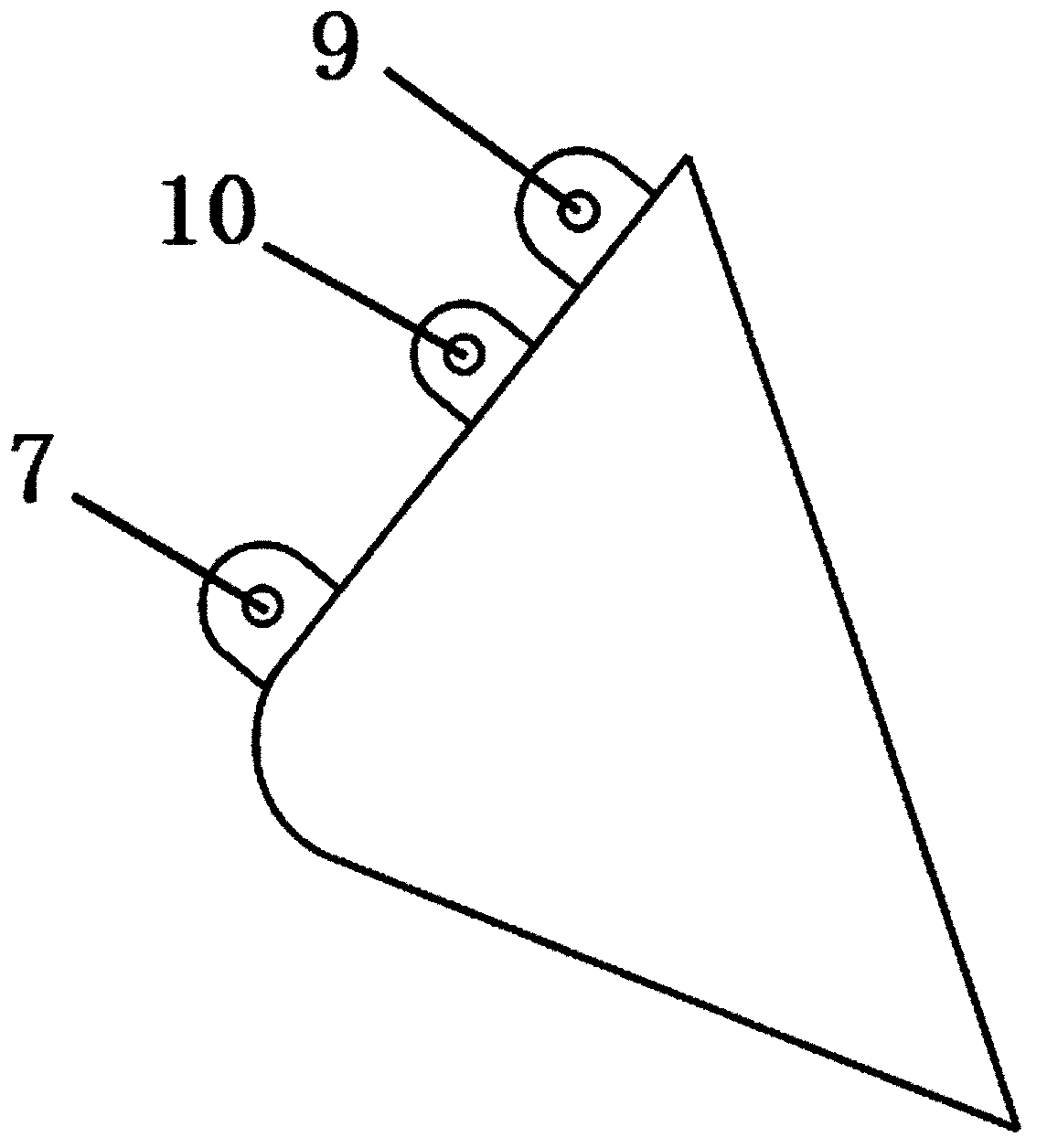

[0024] control figure 1 , figure 2 , image 3 , the first branch chain is composed of the first active rod 3 and the first connecting rod 5, one end of the first active rod 3 is connected to the frame 1 through the first rotating pair 2, and the other end is connected to the frame through the second rotating pair 4 One end of the first connecting rod 5 is connected, and the other end of the first connecting rod 5 is connected with the bucket 8 through the third rotating pair 7 .

[0025] control figure 1 , image 3 , Figure 4 , the second branch chain is composed of a second active rod 6 and a second conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com