A tray automatic push-pull access device

A storage device and tray technology, applied in storage devices, transportation and packaging, can solve the problems of low utilization of shelf space and low storage efficiency, and achieve simple and compact structure, wide application range, accurate and reliable storage and retrieval. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

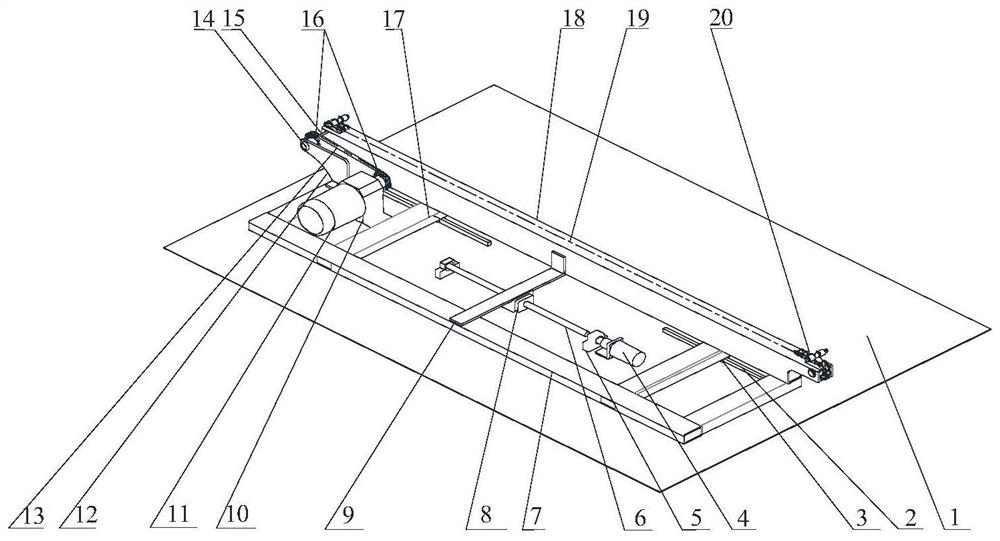

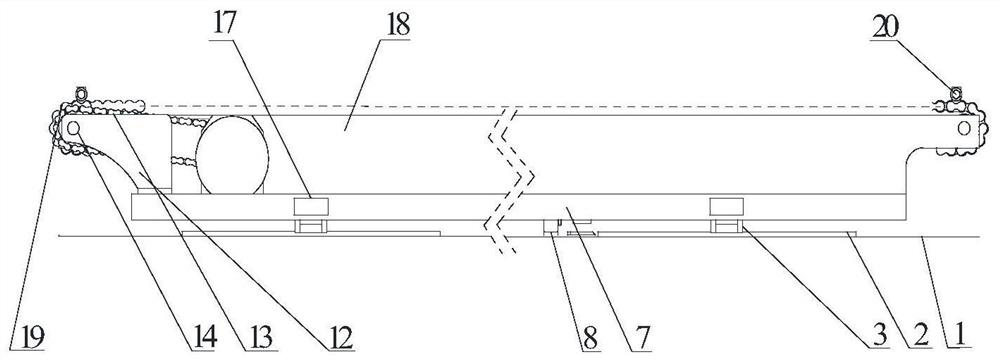

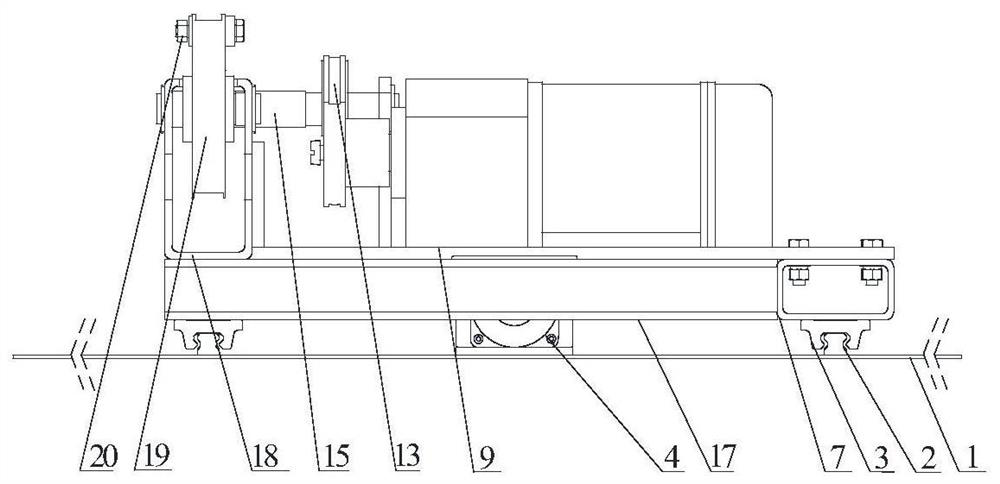

[0025] The present invention will be further described below in conjunction with accompanying drawing:

[0026] This embodiment is a pallet access device that can be automatically pushed and pulled, including a set of chain dragging mechanisms, a set of servo transmission mechanisms installed on the stacker platform, a main beam 18 with a "back"-shaped cross section, The support frame also includes a stacker platform 1, a geared motor 11 and a bearing seat 12 installed on the beam. in:

[0027] The stacker platform 1 is the carrier of the present embodiment, and two groups of guide rails are fixed on the stacker platform, and the two groups of guide rails are distributed on the upper surfaces of the two long sides of the stacker platform; each group has two root rails. The two ends of the longitudinal beam 7 in the support frame are all placed on two guide rails of one group through the slider 3; one end of two beams in the four beams is respectively placed on the other two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com