Drawing and heat-setting device

A heat-setting and stretching system technology, used in textiles and papermaking, etc., can solve problems such as affecting roundness, limiting application scope, and extrusion deformation of hollow fiber membranes, achieving good separation performance, excellent roundness, and operation. handy effect

Inactive Publication Date: 2012-07-25

TIANJIN POLYTECHNIC UNIV

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the multi-machine continuous stretching and heat setting process is adopted, the hollow fiber membrane is easily squeezed and deformed by the stretching roller, which affects its roundness and thus affects the hydrodynamic properties of the processed membrane module; the conventional batch method prepares the hollow fiber membrane The fiber membrane stretching and heat setting devices are easy to maintain the original roundness of the hollow fiber, but as the stretching process proceeds,

It is difficult to continuously adjust the required stretching temperature, which limits its application range

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

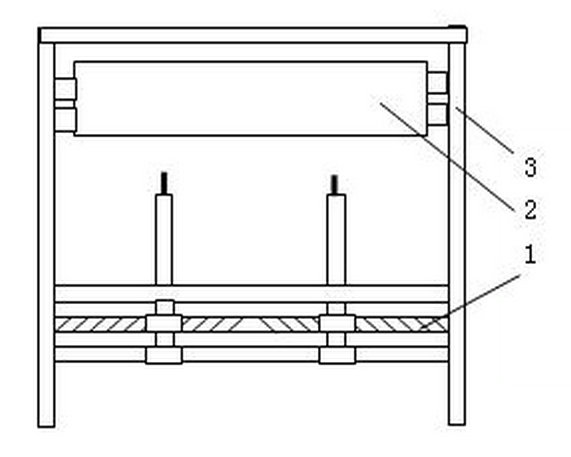

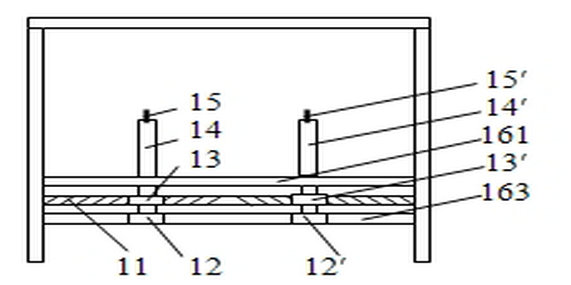

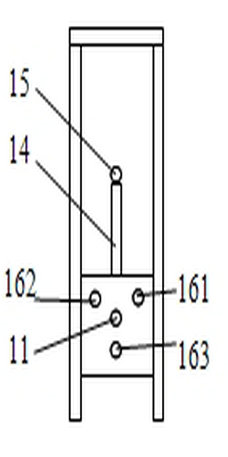

The invention discloses a drawing and heat-setting device, which is used for producing hollow fiber membranes and comprises a frame, a drawing system, a heating system and a transmission control system, wherein the drawing system, the heating system and the transmission control system are installed on the frame. The drawing and heat-setting device is characterized in that the heating system is positioned above the drawing system; the drawing system comprises a left-hand threaded and right-hand threaded screw, three polished rods and two drawing mechanisms in bilateral symmetry; the three polished rods are distributed in an inverted triangular form, and the left-hand threaded and right-hand threaded screw is disposed at the center of the inverted triangle and connected with the transmission control system; the heating system mainly comprises a heating tank and left and right screw lifting mechanisms connected with the same; the transmission control system controls screws of the lifting mechanisms to rotate in the same direction and drives the heating tank to move up and down or pause regularly; an inverted groove is reserved in the middle of the heating tank, and an infrared heating plate is mounted at the inner top of the groove; and the depth and the width of the groove are designed to fit with the length and the diameter of a drawing guide bar, and the length of the groove fits with a largest drawing distance of the drawing guide bar.

Description

technical field The invention relates to hollow fiber membrane manufacturing equipment technology, in particular to a stretching-heat setting device. The device is mainly used to prepare hollow fiber membranes. Background technique Hollow fiber membrane is one of the important types of separation membranes. It is widely used in the field of membrane separation technology because of its high packing density, no need for support materials, simple production process, and miniaturized devices. Stretching pore-forming method is one of the important methods for preparing separation membrane materials. Generally, hollow fiber membranes prepared from polyolefin materials adopt the method of uniaxial stretching to form holes. For example, the polypropylene hollow fiber obtained by melt spinning is stretched and heat-set at a temperature lower than the melting temperature of the polymer and higher than the initial annealing temperature, and a polypropylene hollow fiber microstructu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D02J1/22D02J13/00

Inventor 安树林肖长发张宇峰骆霁月

Owner TIANJIN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com