DSP (digital signal processor) based energy-feedback electronic load grid-connected inverting system and control method thereof

An electronic load and inverter system technology, applied in the direction of high-efficiency power electronic conversion, electrical components, single-network parallel feeding arrangement, etc., can solve the problems of unsuitable low-voltage and high-current DC power supply aging test, heat generation, bulky volume, and waste of electric energy, etc. problems, to achieve good portability, simple maintenance, and good instantaneous response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

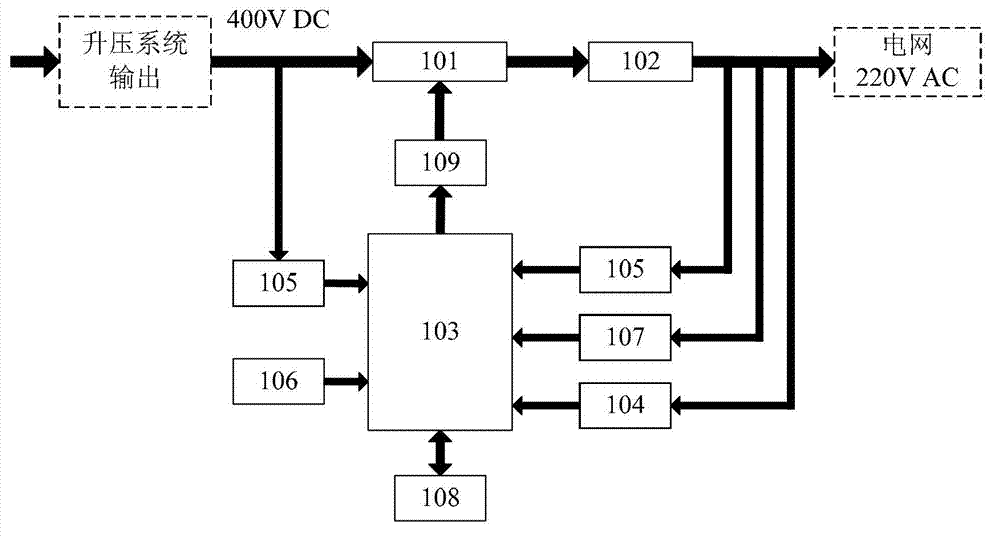

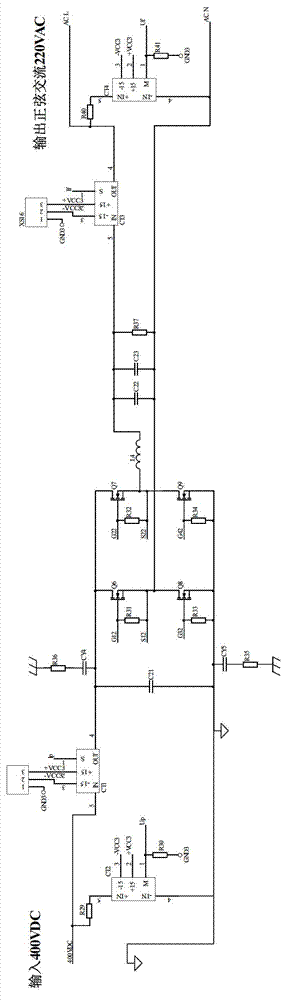

[0048] Such as figure 1 As shown, the DSP-based energy-feedback electronic load grid-connected inverter system of the present invention includes a main circuit and a control circuit, and the main circuit includes a grid-connected inverter module 101 and an output filter module 102 connected in sequence, The grid-connected inverter module 101 is connected to the 400VDC output terminal of the boost system, and the output filter module 102 is connected to the public power grid;

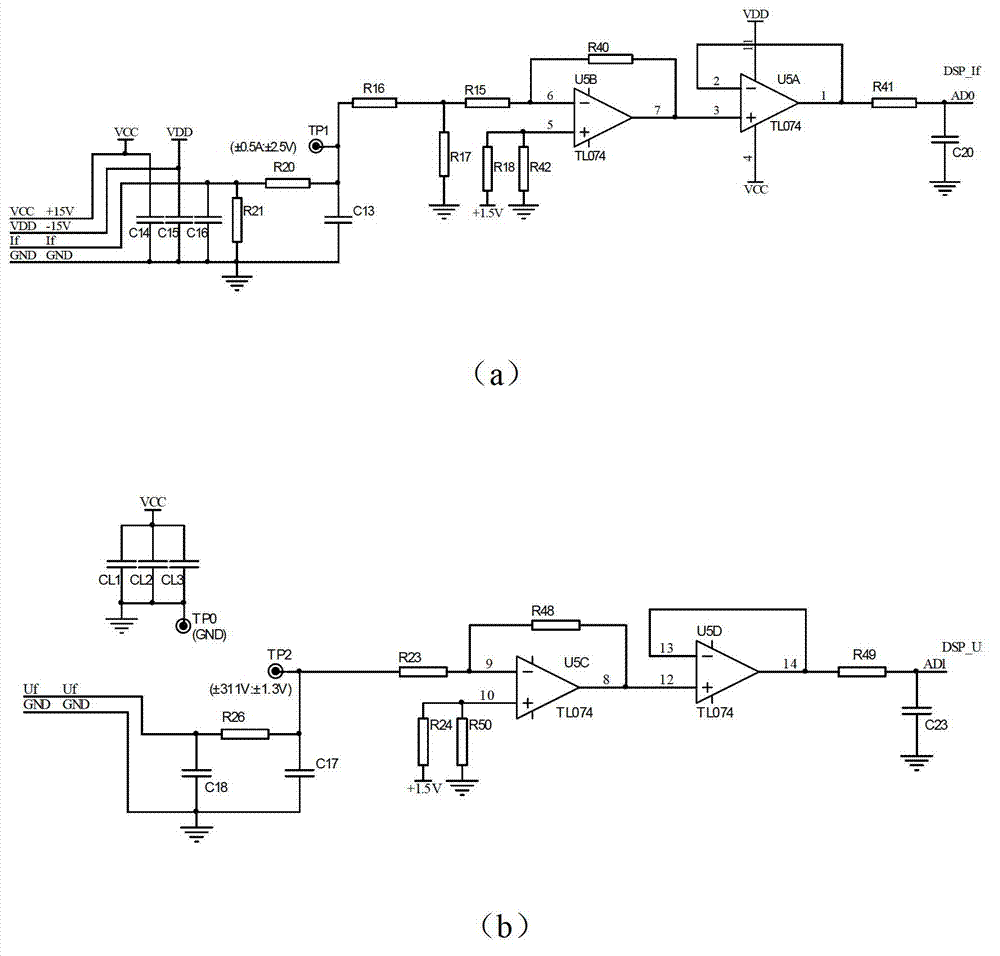

[0049] The control circuit includes a fault protection circuit module, a current and voltage sampling and signal processing module 107 , a human-computer interaction module 108 , a DSP embedded system module 103 and a high frequency drive module 109 .

[0050] The DSP embedded system module 103 is connected with the human-computer interaction module 108, and controls the human-computer interaction module 108. The human-computer interaction module 108 includes an LCD display for displaying the electronic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com