Variable valve timing mechanism

A valve mechanism and valve technology, applied in mechanical equipment, engine components, machines/engines, etc., can solve problems such as insufficient output, limited engine performance, and insufficient power at high speeds to achieve high fuel utilization. , Improve power performance and fuel economy, and reduce exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

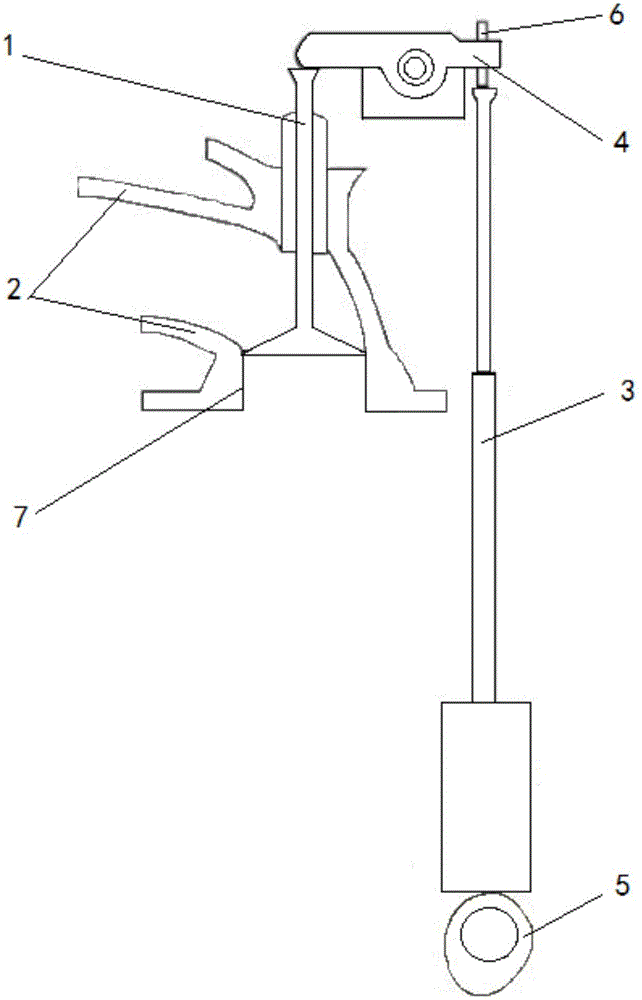

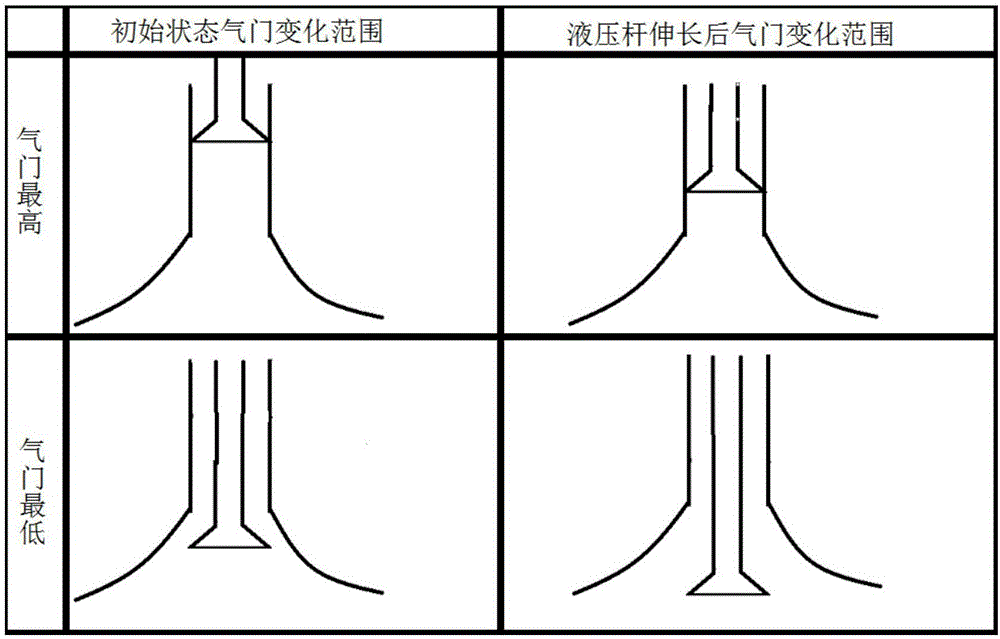

[0025] The invention discloses a variable valve distribution mechanism, such as figure 1 , 2 As shown, it includes a valve 1 and a valve transmission assembly. The valve transmission assembly includes a camshaft, a push rod 3 and a rocker arm 4. The middle part of the rocker arm is hinged to form a lever through the rocker shaft. The rocker shaft is opposite to the cylinder head. 2 fixed, the left end of the rocker arm is against the top of the valve, the right end of the rocker arm is against the top of the push rod, and the lower end of the push rod is against the cam 5 of the camshaft, so The top of the push rod moves up and down, drives the rocking arm to swing around the rocker shaft, and then drives the valve to move up and down. The push rod is an automatically retractable push rod (VPR, Variable Push Rod). When working, the camshaft rotates, and the cam drives the push rod to move up and down. When it swings counterclockwise, the left end of the rocker arm pushes dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com